Dwyer DCP200 User Manual

Page 2

3.0 Pressure Module Maintenance 4

1.0 Installation

Caution: Prior to installing the

DCP100A/200A please review the

operating specifications carefully.

Some operating systems, especially in

pneumatic conveying applications, may see

static pressure or vacuum conditions that

exceed the capability of the

DCP100A/200A pressure module. For

these conditions there are a number of

alternate Dwyer Instruments, Inc. pressure

products that can be used to meet your

application requirements, all of which can

be terminated to the Dwyer

®

DCT1000 Dust

Collector Timer Controller. For more infor-

mation on these and other Dwyer

®

prod-

ucts, please call us at (219) 879-8000, or

visit us on the web at www.dwyer-inst.com

or www.dust-controls.com.

1.1 Location

The system should be located in an enclo-

sure that meets relevant safety standards

and electrical codes. There are no other

special orientation requirements as the

pressure module is not orientation sensitive.

Care should be observed when routing the

air hoses to ensure that any potential con-

densation or moisture will not drain into the

sensor. Where heavy condensation is pre-

sent, a drip loop or an in-line filter should be

installed to ensure long term operation.

1.2 Connections

When a pressure module is installed, the 4-

20 mA process signal and the alarm relay

contacts are available. The circuit may be

used with the internal 24-volt power source

or with an external source. In either case,

the 4-20 mA circuit is isolated from ground

and other signals. The alarm relay contacts

are isolated, normally open contacts.

Pressure connections may be made to the

stepped hose barbs with either 1/8

″ or

3/16

″ I.D. tubing. The following subpara-

graphs describe the external switch con-

nections. Refer to Figure 1 (above) for

switch connection illustration.

1.3 Pressure Module Installation

The pressure module is attached to the

Master Controller using integral connectors

on both units. The insertion ports for the

pressure module are located in the upper

2

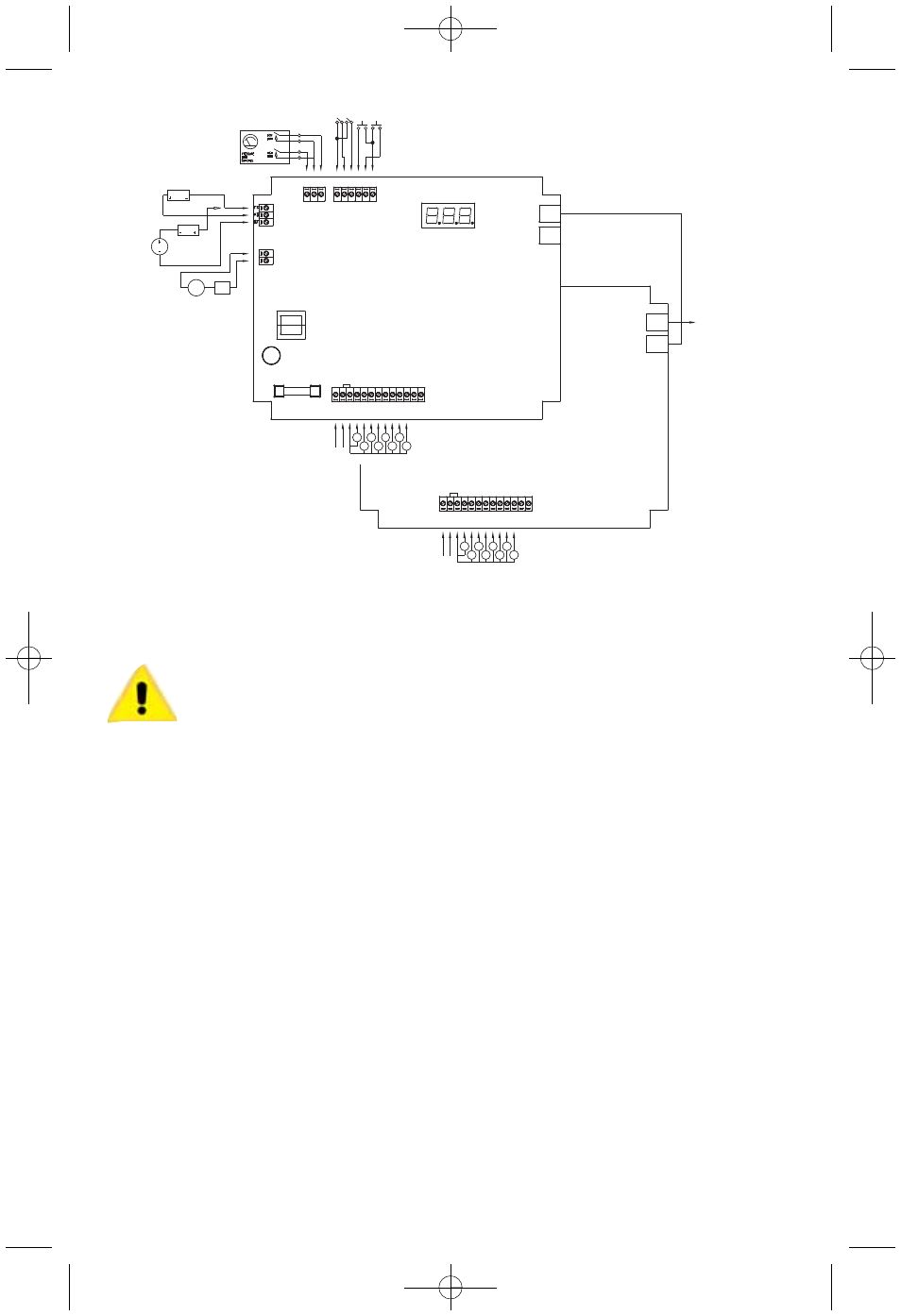

Fig. 1 - Switch

Connections

4-20 mA CONNECTIONS

RECEIVER

USING DCT1000

24V SUPPLY

RECEIVER

SUPPLY

OPTIONAL

CONNECTION

USING EXTERNAL

POWER SUPPLY

4-20 MA

OUTPUT

TB4

4-20 MA

SOURCE

EXTERNAL

INTERNAL ALARM

CONT

ACTS

TB5

NORMALLY OPEN CONTRACTS

MASTER CONTROLLER

MASTER CONTROLLER

INPUT MUST NOT BE

CONNECTED

TO ADDITIONAL

EXPANDER MODULES

SLAVE CHANNEL EXPANDER

HIGH

LIMIT

LOW

LIMIT

COM

TB3

COM

ALARM

MODE

MAN

OVR

D1

CLN

ALARM

RESETCOM

DAISY

CHAIN

OUT

DAISY

CHAIN

IN

DAISY

CHAIN

OUT

DAISY

CHAIN

IN

(INTERNALLY CONNECTED)

TB1

L1

L2

SOL

COM

1

2

3

4

5

6

7

8

9

10

(10 CHANNEL SHOWN)

SOLENOIDS

LINE

INPUT

SOLENOIDS

LINE

INPUT

L1

L2

SOL

COM

1

2

3

4

5

6

7

8

9

10

(INTERNALLY CONNECTED)

TB1

(10 CHANNEL SHOWN)

F1

C3Ø4

SUPPLY

ALARM

LOAD

TB2

E-97-M:dcp100/200module IOM-4/01 8/18/09 4:22 PM Page 2