Dwyer 1600 User Manual

Page 7

Rev. 2/99

7

4309-0700-2

Caution: The components in the control are suseptable

to damage from ESD, electrostatic discharge. Take ap-

propriate action to avoid exposure to ESD. Controls

damaged by ESD are not covered by warranty.

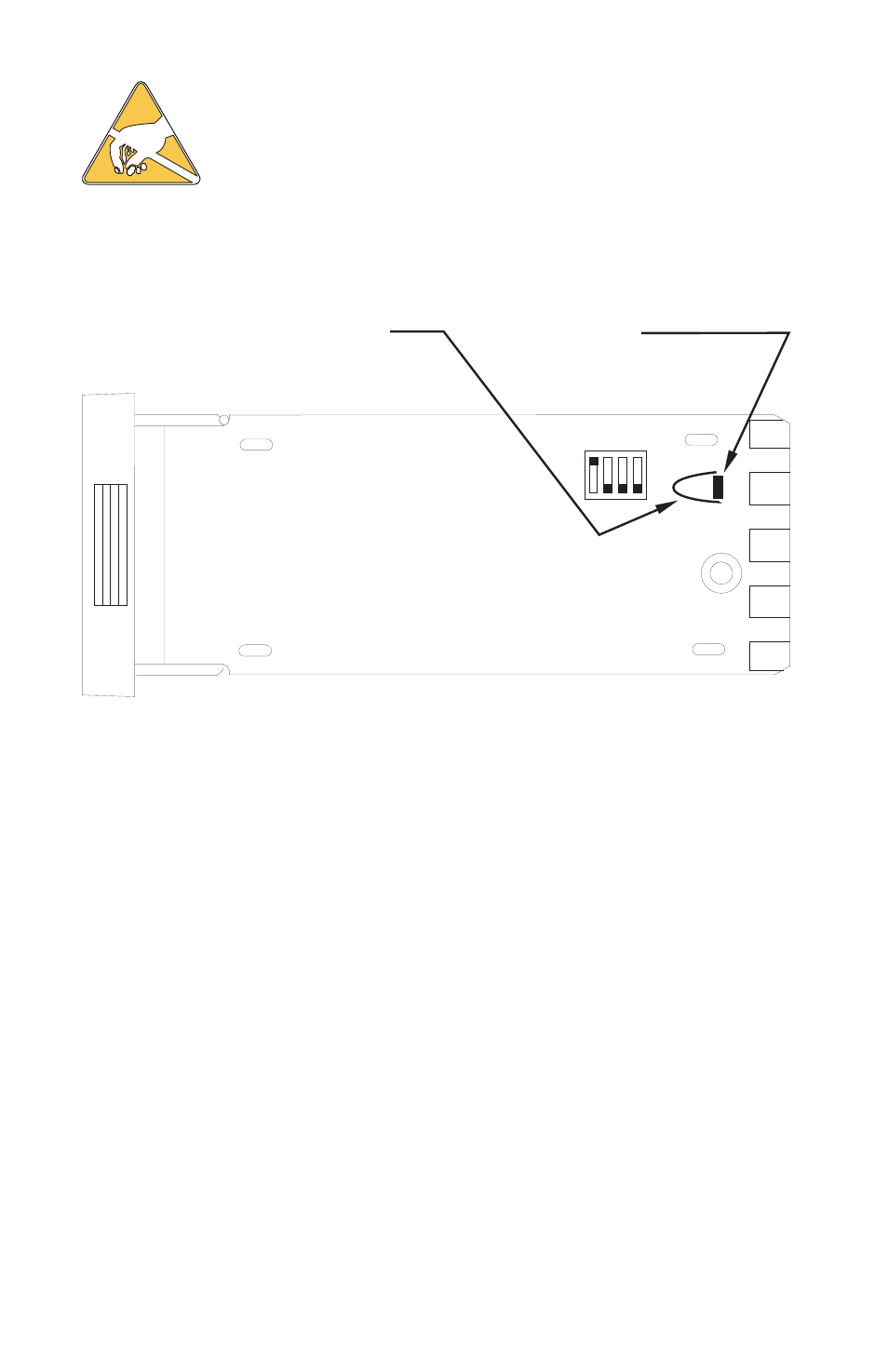

12. Remove the control chassis from the housing. Using Figure E care-

fully solder a small jumper wire across the RJC sensor on the A/D

printed cirsuit board. Allow the board to fully cool before proceding.

Figure E. RJC sensor and jumper location for 1600 Series

R13

RJC Sensor

(may be leaded bead or

surface mount part)

Jumper Across

Component

13. Return to the calibration mode using steps 3, 4, and 5. Press the UP

ARROW key so the lower display reads CAL2. Wait for the reading in

the upper display to stablize.

14. Press the UP ARROW key until the lower display reads CAL7. Refer

to Table 1 for the appropriate input value for the Group you are calibrat-

ing. Read the value in the upper display. Refer to Table 1 for the range

of values appropriate for the Group you are calibrating.

If the displayed value is out of range, the control can not be calibrated

and must be returned to the Factory for service.

If the value is within the specified range, press and hold the ENTER

key and the DOWN ARROW key. (Press the ENTER key first.) The

display will blink to acknowledge the entry.

15. Carefully remove the jumper installed in step 12. Allow time for the

RJC to return to ambient temperature. Return to the calibration mode

using steps 3, 4, and 5. Press the UP ARROW key so the lower dis-