Proximity controls – Dwyer TFLS User Manual

Page 4

MAINTENANCE

Upon final installation of the Series TFLS Tuning Fork Level

Switch, no routine maintenance is required. A periodic check of the

system calibration is recommended. The Series TFLS is not field

serviceable and should be returned if repair is needed (field repair

should not be attempted and may void warranty). Be sure to

include a brief description of the problem plus any relevant

application notes. Contact customer service to receive a return

goods authorization number before shipping.

Bulletin L-33

page 4

©Copyright 2012 Dwyer Instruments, Inc.

Printed in U.S.A. 5/12

FR# 85-443478-00 Rev. 1

PROXIMITY CONTROLS

Phone: 219/879-8000

www.dwyer-inst.com

A DIVISION OF DWYER INSTRUMENTS, INC.

Fax: 219/872-9057

e-mail: [email protected]

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

3. Sensitivity Selection: The sensitivity selection adjusts the fork

sensitivity to material bulk density. The more dense the material,

the lower the sensitivity needed. After installing the probe and

making all electrical connections, set the Fail Safe Selection

switch to the MAX position. Set both the CVD and UNCOVD time

delays to their minimum by rotating them counter-clockwise to the

end position. Rotate the SENSITIVITY potentiometer counter-

clockwise to its end position (See Figure 4). If there is no material

in the tank then the green LED will be illuminated. Fill the tank so

that the fork tines are covered by material. If the green LED turns

off and the red LED turns on then no adjustments are necessary.

If the green LED stays on then rotate the sensitivity potentiometer

clockwise to the point where the green LED goes out and the red

LED comes on. Setting is completed.

4. Time Delay Selection: The time delay is the programmed time

between when the probe senses the presence or absence of

material and when the relay changes state. A time delay is good

for applications that could have false or rapid pulsing of level

indications from sloshing or agitated material. Choose a delay

setting appropriate for the specific application. There are two

potentiometers for adjusting the delay time. The potentiometer

labeled COVD sets the delay time between when the probe is

covered and when the switch changes state. The potentiometer

labeled UNCOVD sets the delay time between when the probe

becomes uncovered and when the switch reverts back to its

normal state (See Figure 4). Adjust the time delay potentiometers

by turning them fully counter-clockwise to their end position. This

setting is no delay. To then set a delay time turn the potentiometer

clockwise to the desired time setting. The delay can be set

anywhere from 2 to 20 seconds.

TROUBLE SHOOTING

If the instrument fails first check that the wiring connections are

correct and that the set up is correct for the application. Next,

check to see if the tines vibrate when free of material.

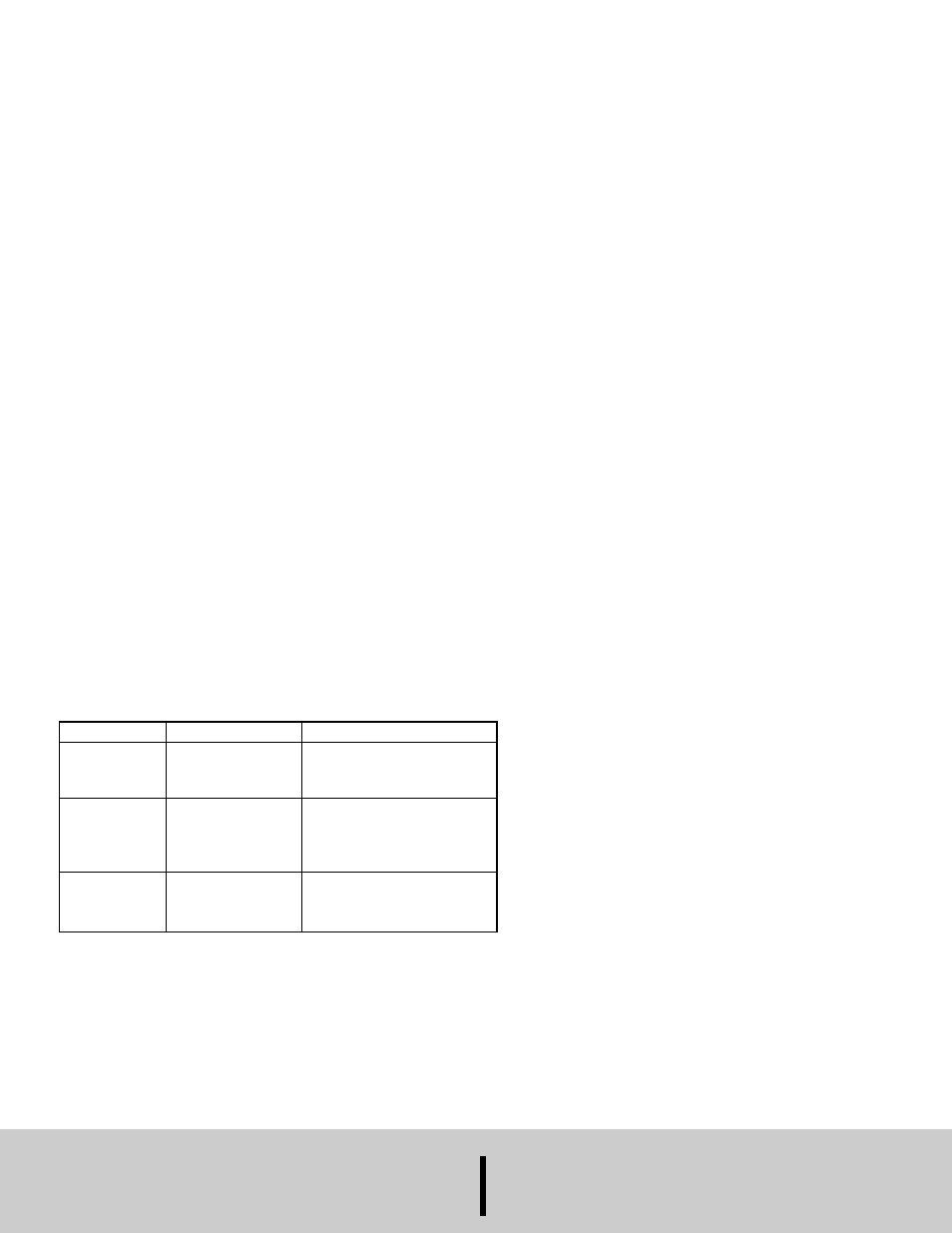

Condition

Probe Covered

Red LED Off

Green LED Off

Probe Covered

Red LED On

Green LED Off

Probe Uncovered

Red LED Off

Green LED On

Relay Status

Terminals 6 & 7 Open

Relay De-energized

Terminals 6 & 7 Open

Relay De-energized

Terminals 6 & 7

Closed

Relay Energized

Probable Cause

No power supplied

Voltage too low

Material too light

Material has formed cavities

Vibration of vessel wall at 85 Hz

Heavy material deposit on fork

Fork Damaged

Vibration of vessel wall at 85 Hz