Dwyer TFLS User Manual

Page 3

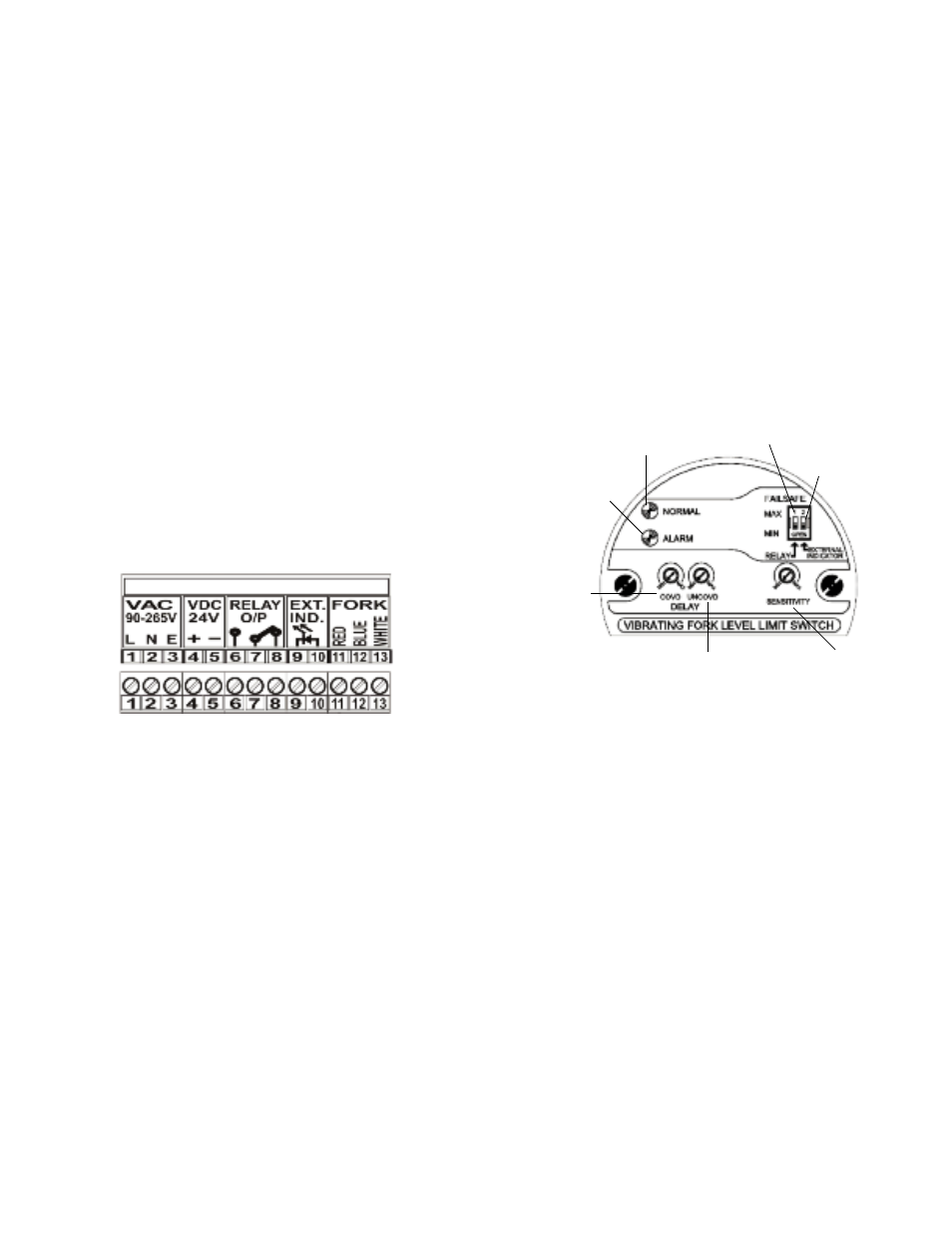

Wiring

Warning: Always install or service this device with the power off

and where required install a disconnect lockout.

Caution: For power line connections use NEC Class 1 wiring rated

60°/75°C. Use 12 to 20 AWG copper only for line and load

connections. Strip the wires 1/4˝.

Note: Installation must be made in accordance with National

Electric Code and local codes and regulations. When fishing wire

through the conduit connection do not allow the wire to touch or

press on components on the boards. Damage to the circuitry may

result.

The TFLS has a 3/4˝ NPT female conduit connection. The conduit

connection must be made such that condensation is not allowed to

enter the housing. If nonmetallic conduit is used, the protective

ground may be connected to the external ground connection

screw.

Strip 1/4˝ of insulation from wires. Connect the power wires to

terminals 4 and 5 if powered by 24 VDC and terminals 1, 2, and 3

if powered by 90 to 265 VAC. Only one type of power supply may

be used at a time, do not connect both AC and DC power

simultaneously. Connect control lines to the relay contact terminals

6, 7, and 8. See Figure 3 for terminals layout.

Figure 3: Terminals

CONTROLS AND INDICATORS (See Figure 4)

Sensitivity Potentiometer — This control sets the sensitivity for

different types of material.

Time Delay Potentiometers — These controls select the delay

times from 2 to 20 seconds from the detection of a level change to

the output. There is one setting for the probe getting covered by

material and one setting for the probe becoming uncovered by

material.

Dip Switch — This two section switch selects the external LED

status and failsafe mode.

Normal LED — Green. This LED is illuminated when the unit is

powered and the fork does not sense any material.

Alarm LED — Red. This LED is illuminated when the relay is

powered by the fork sensing material. It is affected by the delay

setting.

External LED — Red. This external LED is illuminated in

conjunction with the fork being covered or uncovered.

Figure 4:

Switches and LED’s

SETUP AND CALIBRATION

1. Fail Safe Mode Selection: The relay will always be off when the

power fails. In this case the contacts identified as normally open

will be open. The fail safe switch selects whether the normally

open contacts are open or closed when the probe is uncovered.

There are two options for the failsafe condition that are selected by

the RELAY DIP switch (See Figure 4). Selecting MAX will force the

relay contacts to be open when the probe is uncovered and the

NORMAL green LED to be on. Selecting MIN will energize the

relay (closed) when the probe is uncovered and the ALARM red

LED to be on.

2. External LED Selection: The red external LED indicates

material sensing status. There are two options for the LED

condition that are selected by the EXTERNAL INDICATOR DIP

switch (See Figure 4). Selecting MAX will make the LED illuminate

when the probe is uncovered. Selecting MIN will make the LED

illuminate when the probe is covered.

Bulletin L-33

page 3

Failsafe

External LED

Normal Status LED

(Green)

Alarm Status LED

(Red)

Probe Covered

Time Delay

Potentiometer

Probe Uncovered

Time Delay

Potentiometer

Sensitivity