Dwyer F7-EB User Manual

Maintenance (all units)

To Install . . .

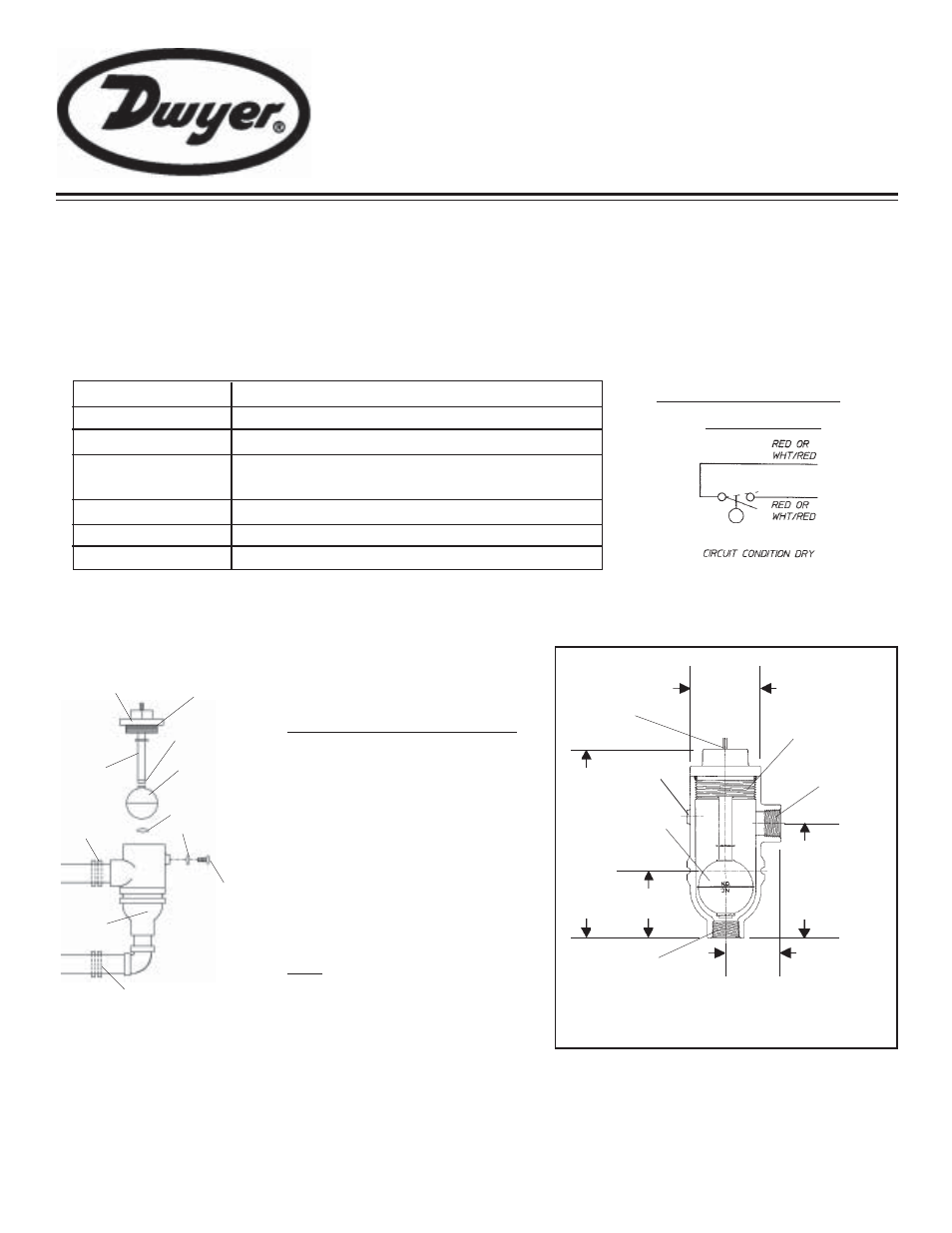

Locate and prepare entrances in tank side so that level switch unit will be in vertical position with wire leads up when

installed on outside of tank. Connect NPT inlet and outlet ports of unit to tank entrances. 1/2" NPT in top of unit

provides for electrical connection. (See wiring information below and on back of sheet.) Use 1/4"-20 threaded

mounting holes to attach unit on any suitable vertical surface.

Externally-Mounted Bottle-Style Level Switches

Model F7-EB

Approvals

- Specifications -

Operating Temperature

Pressure Rating

Electrical Termination

Switch Operation

Mounting Attitude

Switch

-40°F to 300°F (-40°C to 148.9°C)

500 psig Max @ 70°F

No. 18 AWG, 24" L, Polymeric Lead Wires

U.L. Recognized File No. E45168

CSA Report LR 30200

Selectable, N.O. or N.C. by Inverting Float On Stem

Vertical with Lead Wires Up

20 VA (Pilot Duty)

Typical Wiring Diagram

SPST, N.O. or N.C.

Maintenance (All Units) . . .

An occasional "wipe-down" cleaning is the only maintenance normally required.

Standard single level units are

supplied with SPST switch opera-

tion, N.O. (Dry).

To convert operation to N.C. (Dry):

Remove level switch unit from

housing, remove lower grip ring

and invert float on unit stem.

Reinstall lower grip ring into

groove and reinstall level switch

unit** in housing.

**Clean or replace O-ring on

mounting plug (if required) before

reinstalling float/stem assembly

in housing. Mounting plug must

be installed flush with housing.

Note

Switch operation can be selected

without disturbing installation of

unit on tank.

Housing

O-Ring

Stem

Union

Union

or

Pipe Fitting

Mounting

Plug

Groove

Float

Grip

Ring

Lockwasher

1/4-20

Screw

*

Switch actuation level nominal

(Based on a liquid specific gravity of 1.0)

1/2" NPT

(Female)

2 1/4 - 12 Thd.

W/ O-ring

3/4" NPT

Outlet

3/4" NPT

Inlet

Approx.

7"

2" Dia.

Float

2-5/8"

Dia. Ref.

4-1/4"

Ref.

2-1/8"

Dia.

2-1/2"

*

1/4-20 Thd.