Dwyer TFLS User Manual

Page 2

Bulletin L-33

page 2

OPERATING PRINCIPLE

The TFLS incorporates a piezoelectric crystal that vibrates the fork

at its natural frequency, 85 Hz. When the fork comes in contact

with material the vibration is dampened and the switch changes

state. As the fork becomes free of material the switch changes

back to its normal state.

INSTALLATION

Unpacking

Remove the TFLS from the shipping carton and inspect for

damage. If damage is found, notify the carrier immediately.

Mounting Location

The TFLS is rated for industrial environments with few restrictions,

however certain considerations must be made to ensure for

optimal sensing and extended operational life.

• The process temperature and ambient temperature must be

with- in the specified limits for the instrument.

• It is recommended to use a suitable material to protect and seal

the process threads such as TFE tape.

• Position the tines using a wrench on the hexagonal flats above

the process connection. Do not position by turning the housing.

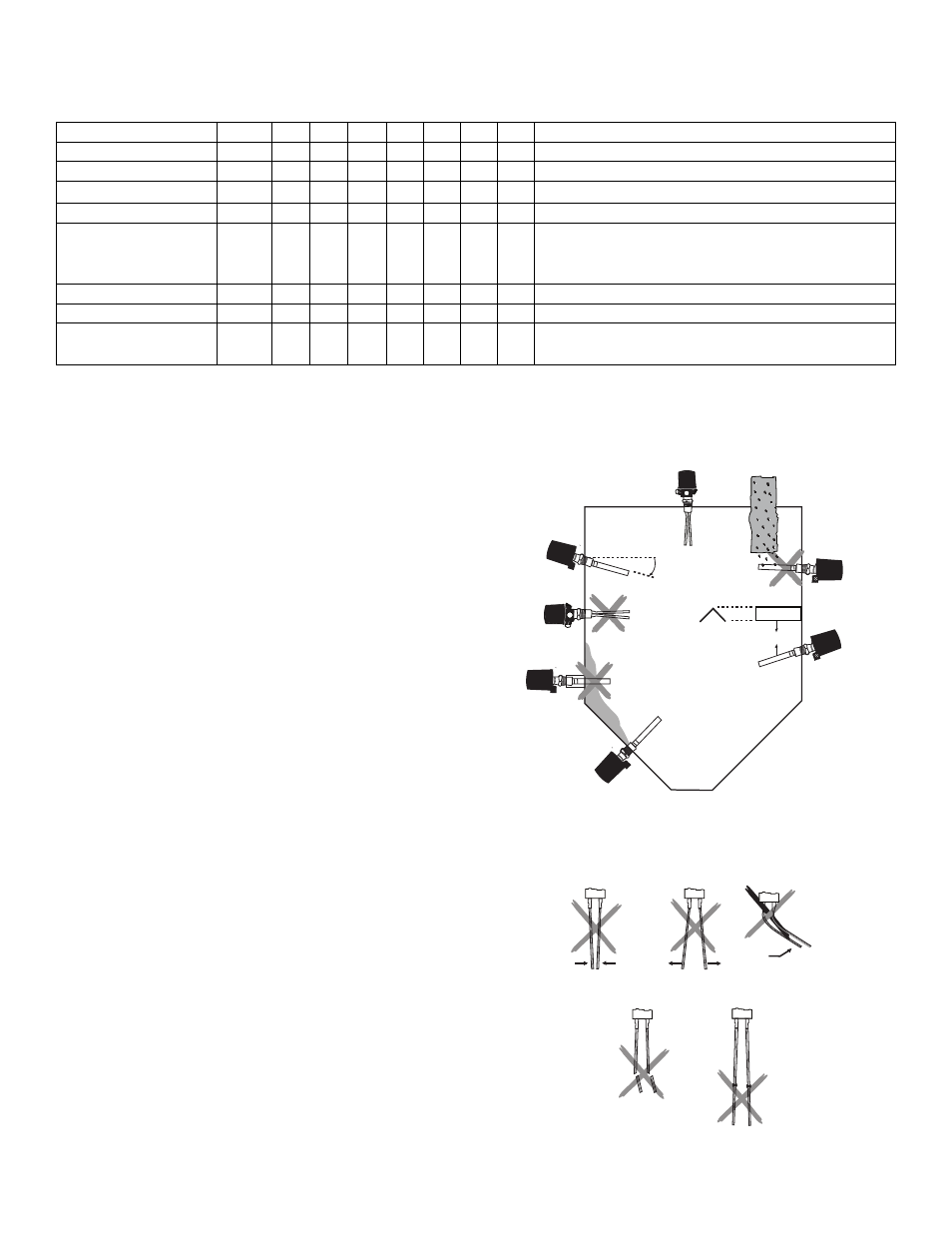

• The probe must be located away from tank inlets or chutes

where material may fall on the probe during filling or emptying

(Figure 1, No. 2). If this is not possible a baffle may be installed

above the probe to protect it from falling material (Figure 1, No. 3).

The baffle must be installed a minimum of 8” (200 cm), see

dimension A in Figure 1, above the probe so that material will not

become packed between the probe and the baffle.

• For mounting horizontally install with conduit entry facing down

so condensate does not enter the enclosure.

• For mounting horizontally position the tines vertically, narrow

edges up, so that material flows freely through them. The TFLS is

designed so that if the conduit opening is pointed down the tines

will be in the proper orientation. No. 6 in Figure 1 shows incorrect

mounting, No. 7 correct mounting.

• For mounting horizontally with materials that may stick to the

tines it is recommended to mount the probe angled down so that

material slides off easily (Figure 1, No. 7).

• The tines should not be bent, shortened, lengthened, or altered

in any way (See Figure 2).

• For top mounting the tines can be mounted in any position

(Figure 1, No. 1).

• When using mounting nozzles, make sure the length is proper so

that the tines extend far enough into the vessel to vibrate free of

material buildup on the vessel wall. Also make sure the nozzle

does not extend further than necessary into the vessel (Figure 1,

No. 5).

Figure 1: Installation Guide

Figure 2: Fork Protection

MODEL CHART

Example

Series

Enclosure

Switch

Power Supply

Probe Type

Process Connection

Probe Length

Options

TFLS

TFLS

W

W

1

1

048

XXX

1

1

EC

SR

EC

ES

1

1

TFLS-W11EC1-048-MT

Tuning Fork Level Switch

Weatherproof

SPDT rated 5A @ 120/240 VAC

24 VDC, 90-265 VAC

Standard Rod

Extension Carbon Steel

Extension 316 SS

1-1/2˝ NPT male

Insertion length in inches (Only for probe type E)

M25 conduit connection

316 SS Enclosure

MT

MT

SS

Do Not Bend

Do Not Shorten

or Extend

A

1

2

3

4

5

6

7