1122 kg/m, 481 kg/m, 80 kg/m – Dwyer PLS User Manual

Page 3

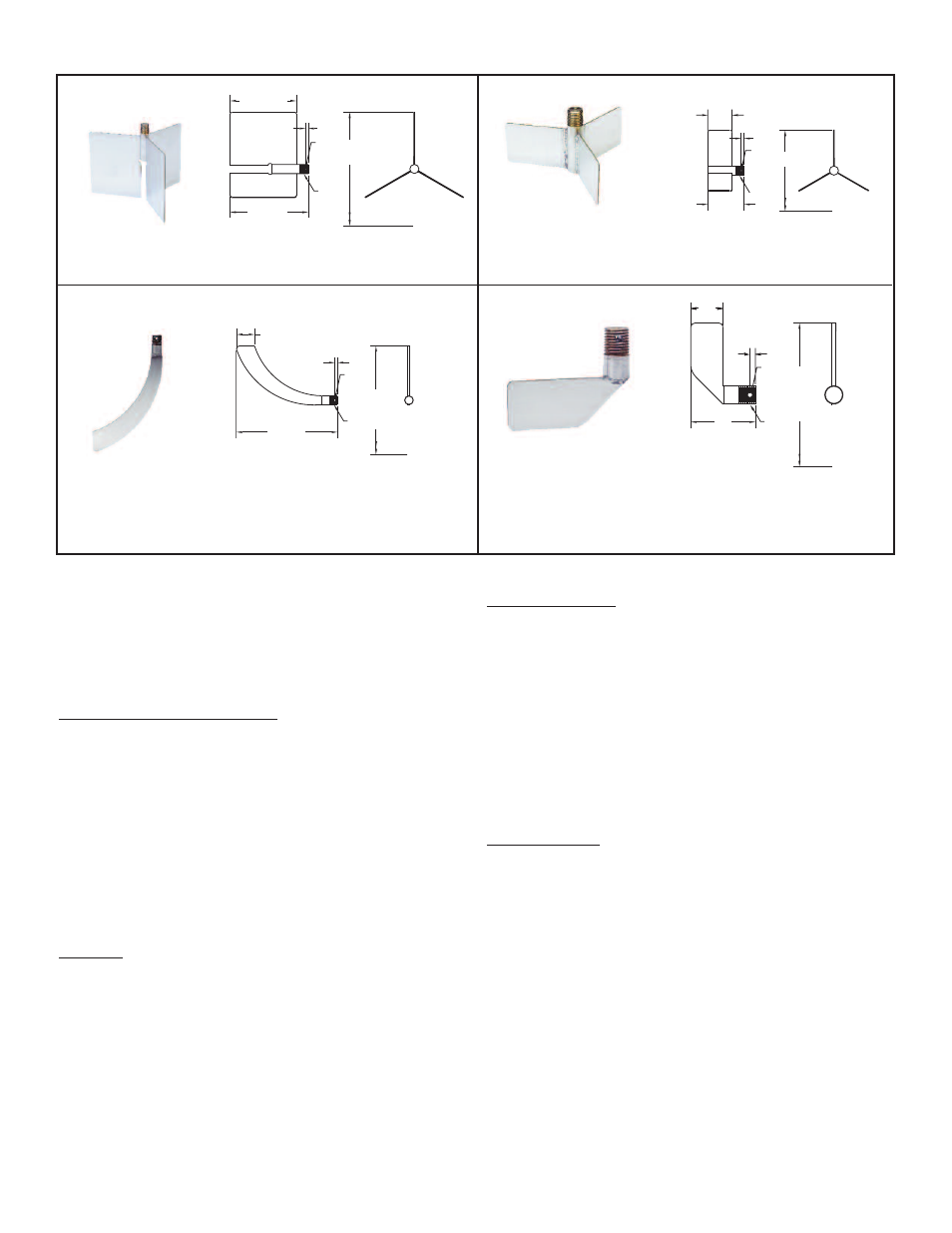

PADDLES

PDL-4. 316 SS single vane paddle for heavy weight materi-

als with a minimum bulk density of 70 lb/ft

3

(1122 kg/m

3

). Fits

through 1-1/4˝ coupling eliminating the need for a mounting

flange.

PDL-2. 316 SS three vane paddle for medium weight mate-

rials with minimum bulk density of 30 lb/ft

3

(481 kg/m

3

).

PDL-1. 316 SS three vane paddle for light weight materials

with a minimum bulk density of 5 lb/ft

3

(80 kg/m

3

).

PDL-3. 316 SS single vane paddle for medium weight mate-

rials with a minimum bulk density of 30 lb/ft

3

(481 kg/m

3

). Fits

through a 1-1/4˝ coupling eliminating the need for a mount-

ing flange.

1-9/64

[28.93]

11/64

[4.32]

6-15/32

[164.13]

1/8

PIN

HOLE

1/4

NPT

TURNS

IN

7˝

[177.80]

CIRCLE

1

[25.40]

11/64

[4.32]

1/8

PIN

HOLE

2

[50.80]

1/4

NPT

TURNS

IN

4-1/2˝

[114.30]

CIRCLE

4-3/32

[103.99]

4-53/64

[122.66]

11/64

[4.32]

1/4

NPT

1/8

PIN

HOLE

TURNS IN

7˝ [177.80]

CIRCLE

1-1/2

[38.10]

11/64

[4.32]

1/8

PIN

HOLE

2-15/64

[56.77]

1/4 NPT

TURNS IN

5˝ [127.00]

CIRCLE

INSTALLATION

Mounting Location

Select a location where the paddle is out of the direct flow of media/material, and

where media does not accumulate permanently. It may be necessary to protect the

paddle with a protective shield or baffle protection.

Protection provided by the equipment may be impaired if the equipment is used with

accessories not provided or recommended by Proximity, or is used in a manner not

specified by Proximity.

Mounting Accessories

Shaft Extensions and Flexible Shaft/Coupling

A standard paddle extension is supplied with all controls that is used to connect the

stub shaft of the control head to a paddle or to an extension shaft constructed of 1/4˝

pipe. Shaft extensions may be purchased from Proximity Controls in carbon steel and

stainless steel. Shaft extensions may also be constructed from 1/4˝ pipe, which is

threaded with 1/4˝ male NPT connections on both ends. Drill .152˝ diameter holes

through the pipe at a distance of .170˝ from each end. These holes should accept a

1/8˝ diameter roll pin. Shaft extensions should not exceed 48˝ in length. Multiple cou-

plings may be connected using coupling model number CPL-1.

Note: All joints should be secured with the 1/8˝ diameter roll pins supplied. Care

should be taken to press pins flush without damaging the bearings of the control.

A flexible shaft/coupling, model number CPL-FLX, may be substituted for the stan-

dard extension. The flexible coupling helps protect the control by absorbing side load-

ing, heavy loading, or loading caused by material surges. It is also recommended for

top mount applications when shaft extensions are used.

Shaft Shields

Shaft shields are recommended for use with shaft lengths over 12˝ to protect the shaft

from side loading. Shaft shields are available from Proximity Controls in carbon steel

and stainless steel. Shields may also be constructed from 1-1/4˝ pipe, which is

threaded with a 1-1/4˝ male NPT connection on one end. Shield pipe should be cut to

cover the shaft length while allowing sufficient clearance between the paddle and bot-

tom of shield. The shaft shield should be securely threaded into a full coupling weld-

ed to the bin or a full coupling mounting flange attached to the bin. Shaft should not

contact the inside diameter of the shaft shield.

Mounting Procedure

Mounting without a Flange

Paddles PDL-1 and PDL-3 will fit through a 1-1/4˝ coupling making a mounting flange

unnecessary. A mounting flange may also be avoided for applications where there is

access to the inside of the bin to attach the paddle from the inside once the switch

control head is installed.

Locate the desired mounting point and cut a hole in the bin of the proper diameter to

insert a 1-1/4˝ pipe coupling. For mounting without a shaft shield weld a 1-1/4˝ half

pipe coupling to the bin wall so that the coupling is flush with the interior wall. For

mounting with a shaft shield weld a 1-1/4˝ full coupling so that the coupling is halfway

into the bin. If using a PDL-1 or PDL-3 attach the paddle to the switch control head,

if not already connected, by screwing into the 1/4˝ NPT connection on the shaft and

inserting the roll pin. Attach the switch control head to the pipe coupling buy inserting

the paddle through the coupling and screwing in. If attaching the paddle from the

inside then first attach the switch to the coupling and then attach the paddle from the

inside of the bin as described above.

Mounting with a Flange

Paddles PDL-2 and PDL-4 will require flange mounting if the interior of the bin is not

accessible. Half coupling flanges (Models FLG-CSH and FLG-SH) should be used on

installations not requiring a shaft guard. Full coupling mounting flanges (Models FLG-

CSF and FLG-SSF) should be used with installations requiring a shaft guard.

If the mounting flange is used on a flat surface, layout a 7˝ bolt circle. The flange is

designed with clearance holes for 1/4˝ bolts or screws. Drill and tap 6 holes equally

spaced, on the bolt circle, of the appropriate thread type. At the center cut a hole of

sufficient clearance diameter to allow insertion of the paddle selected. It may be nec-

essary to tack weld bolts or screws to the flange or inner surface of the bin. On bins

with curved surfaces it may be necessary to create a template, which will follow the

contour of the bin wall, in order to locate the hole positions. Use the gasket supplied

if required between the bin wall and flange.