Dwyer instruments, inc – Dwyer 672 User Manual

Page 2

©Copyright 2009 Dwyer Instruments, Inc.

Printed in U.S.A. 4/09

FR# R1-443716-00

MAINTENANCE

Routine inspection is not required except for periodic inspection of the

cable and molding to ensure that these are neither damaged nor softened

by incompatible liquid. A periodic check of the zero and span settings is

also recommended. Otherwise these transmitters are not field serviceable

and should be returned to the factory if repair is needed. Be sure to include

a brief description of the problem plus any pertinent application information

available.

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000

www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A.

Fax: 219/872-9057

e-mail: [email protected]

MOUNTING

The pressure transducer is designed to be attached by the coupling

thread, and can be mounted in any plane or direction. To tighten the fit, use

a 5/8 UNF AF (M16) wrench on the hexagon provided and apply a

maximum torque of 20 lb-ft (27 N-m). The customer must assure that the

pressure seal is suitable for the application.

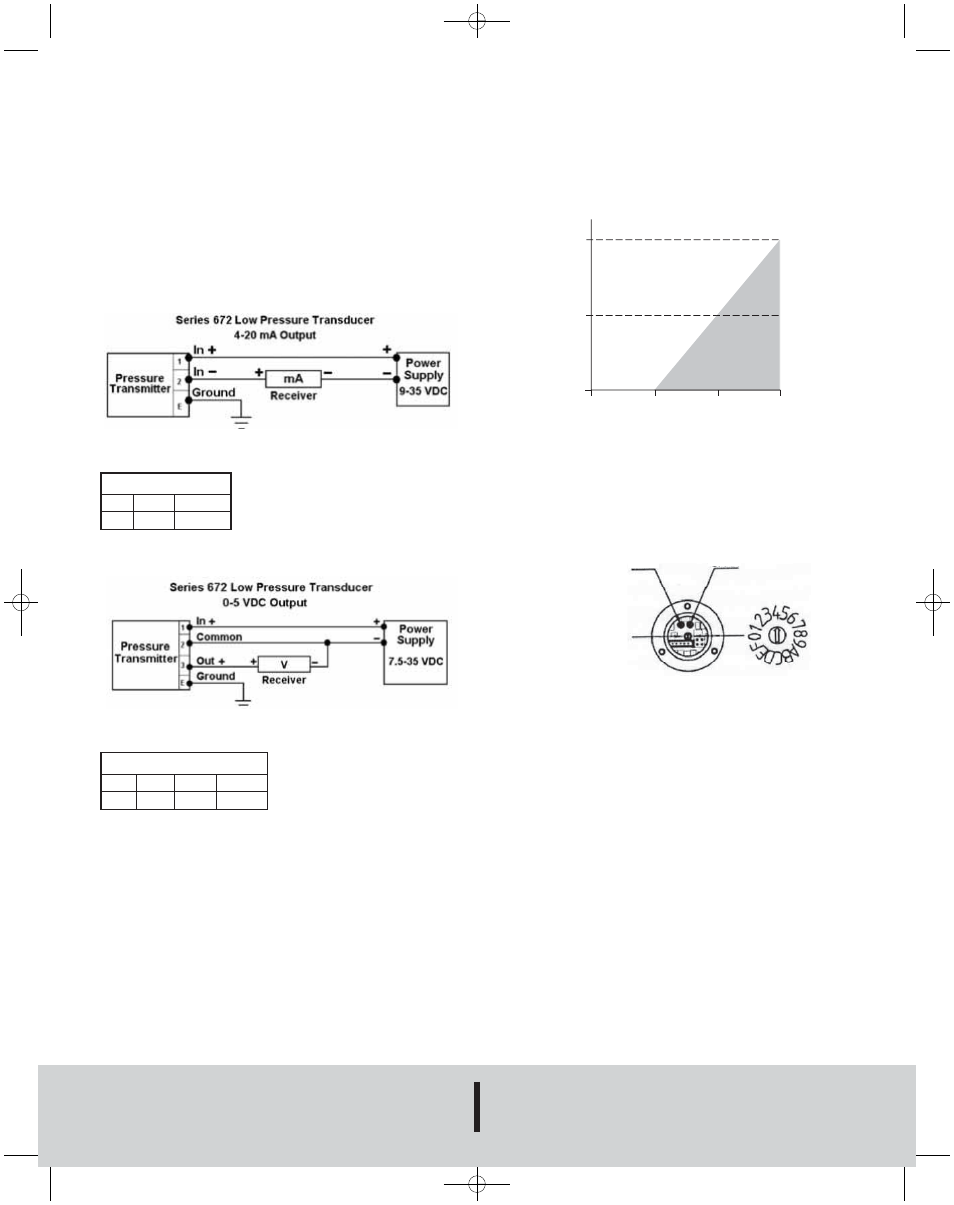

ELECTRICAL

Electrical Connections:

Electrical connections are made by way of a DIN 43650 connector with

mating plug.

Load Resistance (4-20 mA Transducer)

The total permissible resistive load in the loop (to include all cable

resistance) can be from zero to (50x supply voltage – 9) ohms, e.g. with a

12 VDC supply, the permissible load is from zero up to 150 ohms.

ZERO/SPAN ADJUSTMENT

Zero and span controls are precisely set during manufacturing and should

only need adjustment if there is a change in the required pressure

measurement. Inquire with Dwyer Instruments, Inc. before adjustment.

RLOOP1MAX = 50 (VSUPP-9)

1325

575

0

0

9

20

35

TOT

AL RESIST

ANCE

(OHMS)

SUPPLY VOLTAGE

(VDC)

ZERO

SPAN

RANGE SWITCH

4-20 mA Output

ln+

1

ln-

2

Ground

E

0-5 VDC Output

ln+

1

Com

2

Out+

3

Ground

E

A-30-672:TEMPLATE 4/9/09 11:15 AM Page 2