Dwyer 672 User Manual

Dwyer instruments, inc, Series 672 low pressure transducer

Bulletin A-30-672

The Series 672 Low Pressure Transducer is a perfect solution to any

application where a very accurate low pressure transducer is necessary.

Using variable capacitance technology, the series 672 is designed to

measure pressures as low as 10˝ w.c. up to 400˝ w.c., very low ranges for

a single pressure transducer. The 672 also features a 0.25% F.S. accuracy.

Use the Series 672 in liquid level, flood warning, waste water, clean room,

and open channel flow applications.

GENERAL WARNINGS

• Transducer should not be subjected to greater than the maximum

allowable pressure or temperature as defined in the specifications.

• Transducer should not be subjected to mechanical impact.

• In the event of fire the end user must ensure that the system pressure is

vented to a safe area.

• The effects of decomposition of unstable fluids should be considered

when placing this device in service.

• The pressure transducer has no means of draining or venting, this must

be performed by another component in the end user’s system.

• The pressure range of the transducer must be compatible with the

maximum pressure being measured.

• Pressure media must be compatible with the transducer wetted parts

which are: UNS 31803 Stainless Steel, Ceramic, and Fluoroelastomer

(FKM).

• Exposed end of cable must be kept free from moisture.

• Liquid must not be allowed to freeze in the pressure port.

• Avoid mounting the transducer near a heat source that is likely to create

a temperature gradient across the instrument. If this is unavoidable, use

a heat shield to deflect uneven radiated heat or wrap the transducer in

insulation so that even temperature is assured throughout.

• The transducer should not be removed while the measured system is at

pressure.

• Care must be taken not to touch the pressure sensitive diaphragm while

cleaning the pressure port. This may cause irreparable damage.

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000

www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A.

Fax: 219/872-9057

e-mail: [email protected]

SPECIFICATIONS

Service: Compatible liquids and gases.

Wetted Materials: 318 Duplex SS, Ceramic, Fluoroelastomer (FKM).

Housing Material: 318 Stainless Steel.

Accuracy: ±0.25% F.S. (RSS). *Includes non-linearity, hysteresis, and

non-repeatability.

Stability: 0.25% F.S./1 year.

Temperature Limits: -40 to 212°F (-40 to 100°C).

Pressure Limits: 29 PSI (2 bar) for up to 85˝ w.c. (0.2 bar) ranges; 58 PSI

(4 bar) for 85˝ to 140˝ w.c. (0.2 to 0.35 bar); 73 PSI (5 bar) for 141˝ to

400˝ w.c. (0.35 to 1 bar).

Compensated Temperature Limits: -5 to 140°F (-20 to 60°C).

Thermal Effects:

Zero: 1.0%F.S./100°F (2.0%F.S./100°C).

Span: 1.0%F.S./100°F (2.0%F.S./100°C).

Power Requirements:

4-20 mA: 9-35 VDC

0-5 VDC: 7.5-35 VDC

Output Signal: 4-20 mA (2-wire) or 0-5 VDC (3-wire).

Zero & Span Adjustment: ±10% F.S. each (by Potentiometer).

Response Time: 5 ms.

Max Loop Resistance: 1.325 kΩ.

Electrical Connections: Large DIN 43650 connector with mating plug.

Enclosure Rating: NEMA 4X (IP65).

Process Connection: 1/4”-18 NPT male.

Weight: 11.6 oz (330 g).

Agency Approval: CE.

CE STANDARDS TESTED TO:

ELECTRO MAGNETIC COMPATIBILITY

Standards Applied

EN50081-1:1992

EN61000-6-2:1999

TEST METHODS/PROCEDURES

EN50081-1:1992

EN61000-6-2:1999

EN6100-4-2:1995 + A1:1998

EN61000-4-3:1996

EN61000-4-4:1995

EN61000-4-6:1996

Specifications - Installation and Operating Instructions

Series 672 Low Pressure Transducer

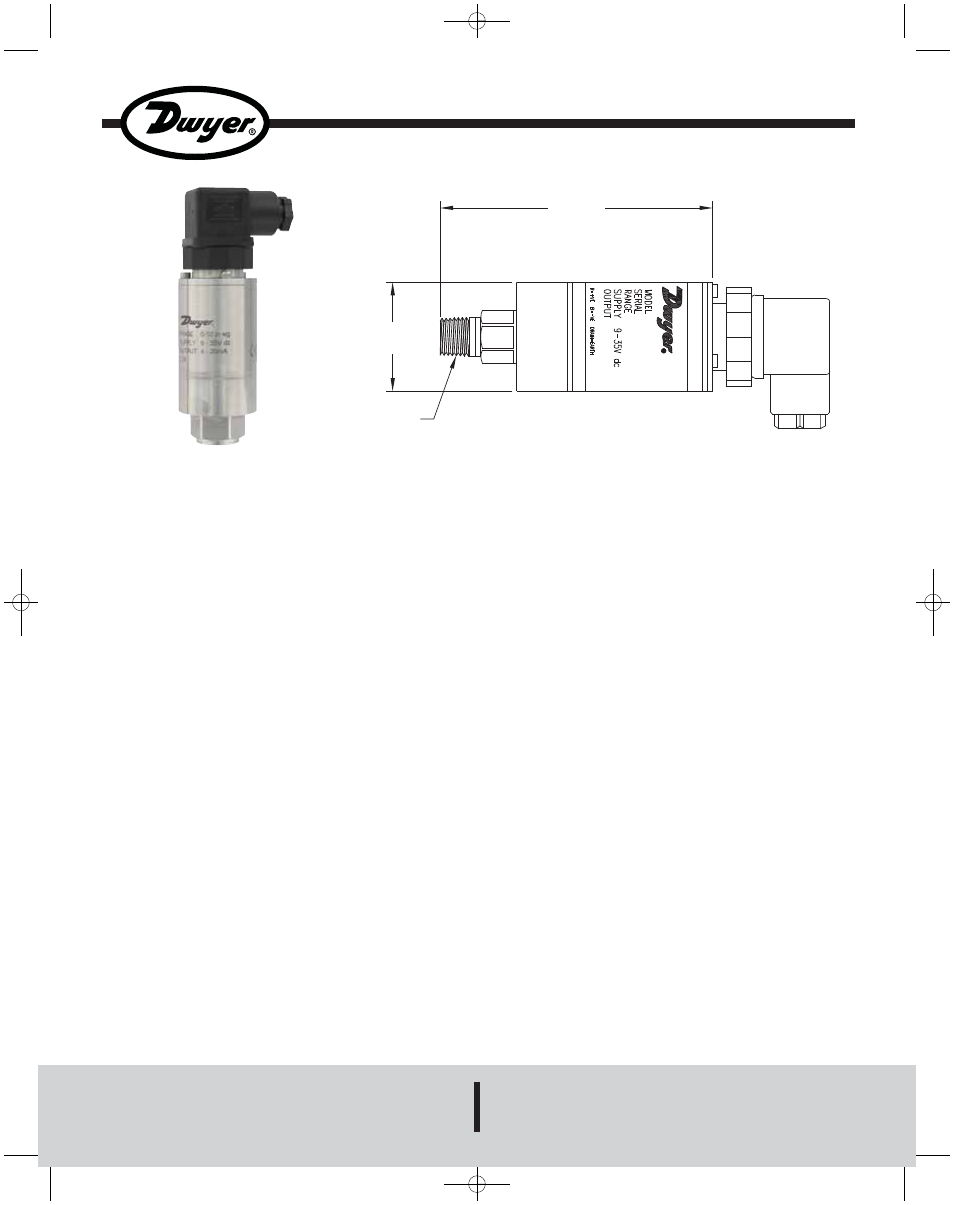

3-3/4 [95.48]

ø1-1/2 [38.10]

1/4 MALE NPT CONNECTION

A-30-672:TEMPLATE 4/9/09 11:15 AM Page 1