Dwyer instruments, inc – Dwyer 3000SGT User Manual

Page 4

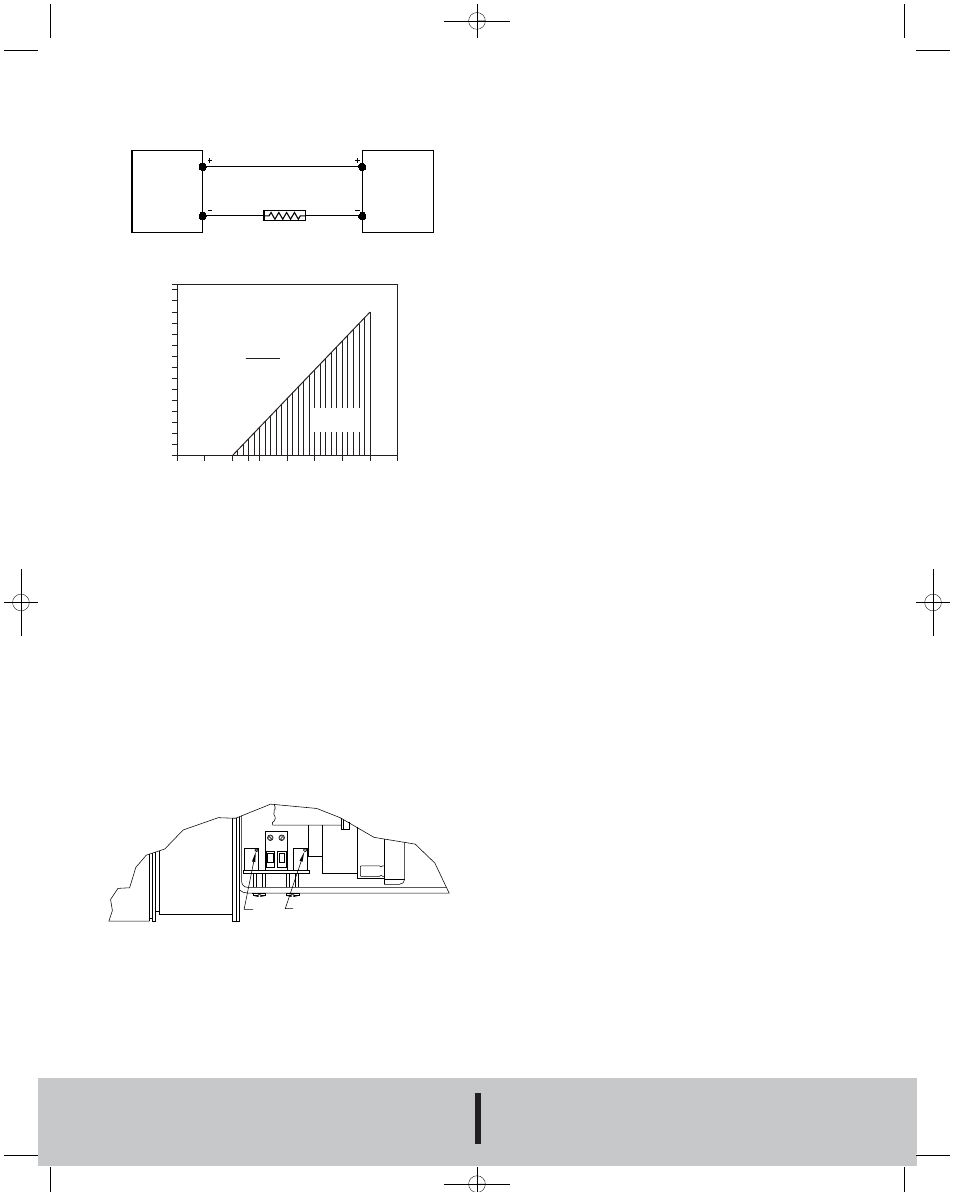

Voltage Input

The PHOTOHELIC

®

SGT can easily be adapted for receivers requiring 1-5 VDC

input. Insert a 250 ohm, 1/2 watt resistor in series with the current loop but parallel

to the receiver input. Locate this resistor as close as possible to the receiver input.

Because resistor accuracy directly influences output signal accuracy, we

recommend use of a precision ±0.1% tolerance resistor to minimize this effect.

Transmitter Output Calibration

Each unit is factory calibrated to produce 4mA DC of loop current at zero pressure

and 20mA DC at full scale. To check calibration use the following procedure.

1. Connect a controllable source of pressure to the high pressure port and leave

the low pressure port vented to atmosphere.

2. With transmitter connected to its companion receiver and power supply, insert

an accurate milliammeter ranged to approximately 30 mA in series with the

current loop.

3. Apply electrical power to the system and check for proper operation. Slowly

apply pressure and confirm that loop current increases above the 4 mA zero

pressure value.

4. Span and zero controls are located behind the terminal board as shown in

Figure L. Apply pressure until gage reads full scale and adjust span control for

20 mA loop current.

5. Relieve pressure and adjust the zero control for a reading of 4 mA loop current.

6. Zero and span controls are slightly interactive so steps 4 and 5 should be

repeated until outputs are consistently 4 and 20mA, respectively.

7. Remove the milliammeter from the current loop, make connections to system

pressure sources and place unit in service.

Multiple Receiver Installation

An advantage of the standard 4-20 mA DC output signal used in Series 3000 SGT

switch/gage/transmitters is the compatibility with a wide range of receivers. Devices

such as the A-701 Digital Readout, a chart recorder and other process control

equipment can all be operated simultaneously. It is only necessary that all devices

be designed for a standard 4-20 mA DC input, the proper polarity of input

connections be observed and the combined receiver resistances not exceed the

maximum for the current loop. If any receiver indicates a negative or downscale

reading, the signal input leads are reversed.

Maintenance

After final installation of the PHOTOHELIC

®

SGT no routine maintenance is

necessary. A periodic check of calibration is recommended following the procedure

under TRANSMITTER OUTPUT CALIBRATION. Otherwise, these units are not

field repairable and should be returned, freight prepaid, to the following address if

service is necessary. Be sure to include a brief description of the problem plus any

relative application information available.

Dwyer Instruments, Inc.

Attn: Repair Department

102 Highway 212

Michigan City, IN 46360

SERIES

3000 SGT

PRESSURE

TRANSMITTER

RECEIVER

POWER

SUPPLY

10-35 VDC

SPAN

ZERO

Figure J

Figure L

MAXIMUM VALUE (1250Ω)

RL MAX. = Vps-10.0

20 mA DC

OPERATING

REGION

1500

1400

1300

1200

1100

1000

900

800

700

600

500

400

300

200

100

50

T

O

T

AL RECEIVER RESIST

ANCE (

Ω

)

0

5

10 13 15

20

25

30

35

40

VDC

NOTE: RECEIVER MAY BE IN SERIES WITH

+ OR - LEG OF CONTROL LOOP

©Copyright 2010 Dwyer Instruments, Inc.

Printed in U.S.A. 12/10

FR# 13-440202-05 Rev.3

Figure K

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361 U.S.A.

Phone: 219/879-8000

www.dwyer-inst.com

Fax: 219/872-9057

e-mail: [email protected]

B-36A:bulletin B-36A 12/13/10 10:18 AM Page 4