Operating instructions, General operating instructions, Shutdown instructions – Badger Meter Oscillating Piston Meter User Manual

Page 9: Operating instructions 9

OPERATING INSTRUCTIONS

General Operating Instructions

The instructions for operating an oscillating piston meter depend on the meter-accessory combination and the type of flow

control devices used in the facility piping In general, the operation is either manually controlled or accessory controlled

Manual operation applies to metering applications employing hand-operated valves or other manually-activated, flow-

regulating devices that are not functionally controlled by a meter-accessory device Accessory controlled operation is used in

metering applications involving meter-accessories that provide a signal output to activate and/or deactivate a valve or other

type of flow control device

REGARDLESS OF THE OPERATING PROCEDURE USED, THE VALVES OR DEVICES CONTROLLING THE FLUID FLOW

THROUGH THE METER MUST ALWAYS BE OPENED AND CLOSED SLOWLY TO PREVENT SHOCK LOADS THAT MAY

DAMAGE THE PISTON.

Manual Operation

Instructions are limited to the following start and stop procedures The procedures are intended for use in simple metering

applications where the flow of fluid through the meter is controlled by hand-operated valves located in the facility piping

upstream and downstream of the meter

1 Slowly open the upstream valve to apply fluid to the meter

2 Slowly open the downstream valve to initiate metering

3 Adjust the downstream valve so the flow rate does not exceed the flow rate specification of the meter

NOTE:

N

On meters equipped with an accessory device providing a totalizing indicator, the flow rate can be checked by timing

the number of gallons registered in one minute

4 To stop metering, slowly close the downstream valve; then close the upstream valve

Accessory Controlled Operation

The step-by-step operating procedures used in accessory controlled metering applications are dependent on the specific

function of the accessory employed and its electrical interconnection with a flow control device or devices See the

accessory's User Manual for specific operating instructions

Shutdown Instructions

If a meter is to be shut down for an extended period of time (particularly when the application involves the metering

of slurries or abrasive solutions), its measuring chamber should be thoroughly flushed out to prevent the settling

out of undissolved solids or the accumulation of corrosive deposits See

“Preventive Maintenance” on page 10

for

cleaning instructions

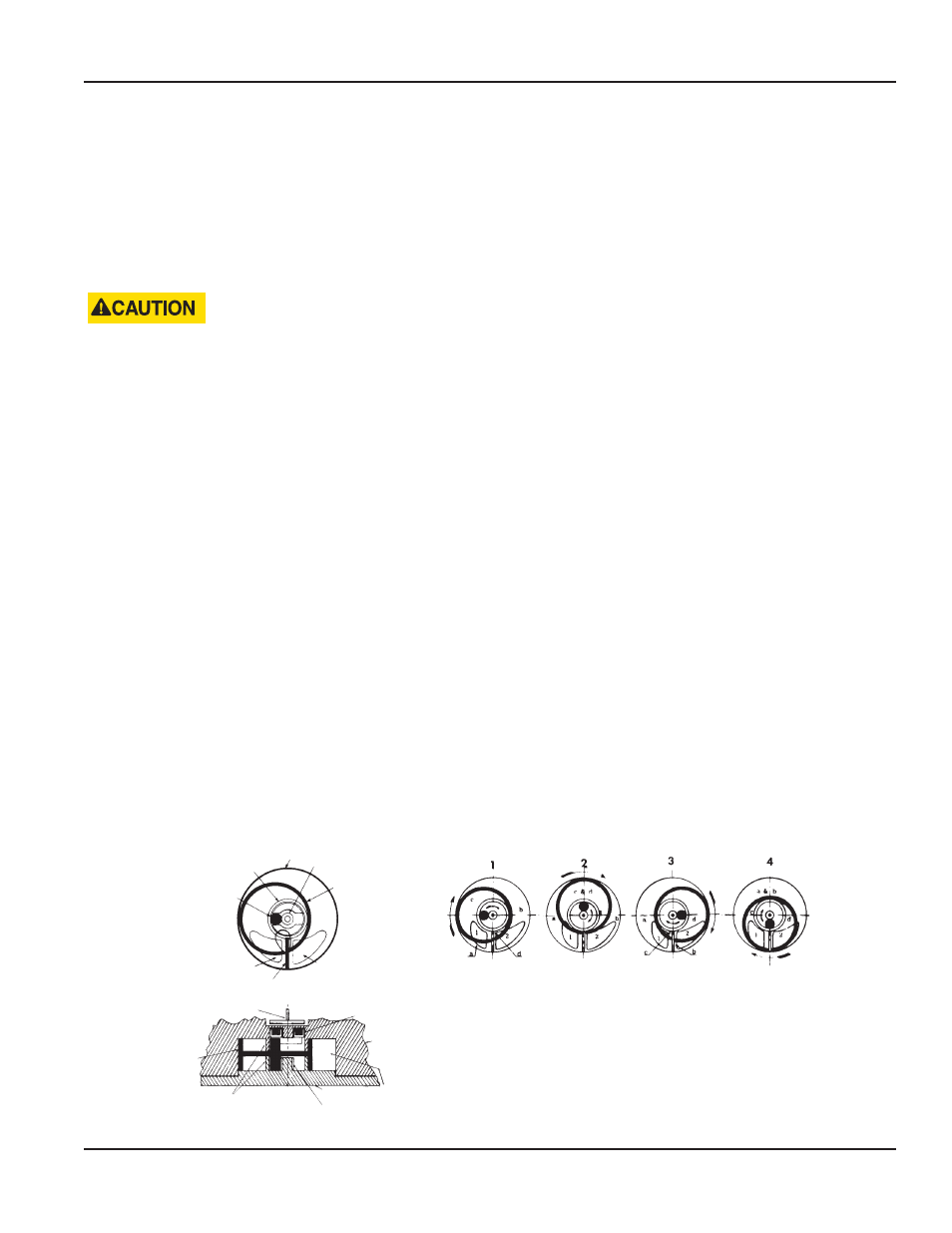

MEASURING CHAMBER

PISTON

CONTROL ROLLER

CYLINDRICAL

ABUTMENT

PISTON HUB

OUTLET PORT

PARTITION PLATE

INLET PORT

FOLLOWER MAGNET

MAGNET ASSEMBLY

HOUSING

MEASURING

CHAMBER

COVER

CONTROL ROLLER

CYLINDRICAL ABUTMENT

PISTON

Diagram 1

Spaces "a" and "c" are receiving liquid from the inlet port "1"

and spaces "b" and "d" are discharging liquid through the

outlet port "2".

Diagram 2

The piston has advanced and space "a" in connection with the

inlet port "1", has enlarged; and space "b" in connection with

the outlet port "2", has decreased. Spaces "c" and "d", which

have combined, are about to move into position to discharge

through the outlet port "2".

Diagram 3

Space "a" is still receiving liquid from the inlet port "1" and space

"c" is just opening again to the inlet port. Spaces "b" and "d" are

discharging through the outlet port "2".

Diagram 4

Liquid is being received by space "c" from the inlet port "1"

while liquid is being discharged from spaces "d" through the

outlet port "2". Spaces "a" and "b" have combined and are

about to discharge through the outlet port "2", as the piston

moves around to occupy the position as shown in Diagram 1

to begin the cycle again.

Figure 5: Shutdown Instructions

User Manual

Page 9

August 2013