Badger Meter GMD Gage User Manual

Location, Installation, Operation

LOCATION

A. The GMD can be line, bracket or panel mounted.

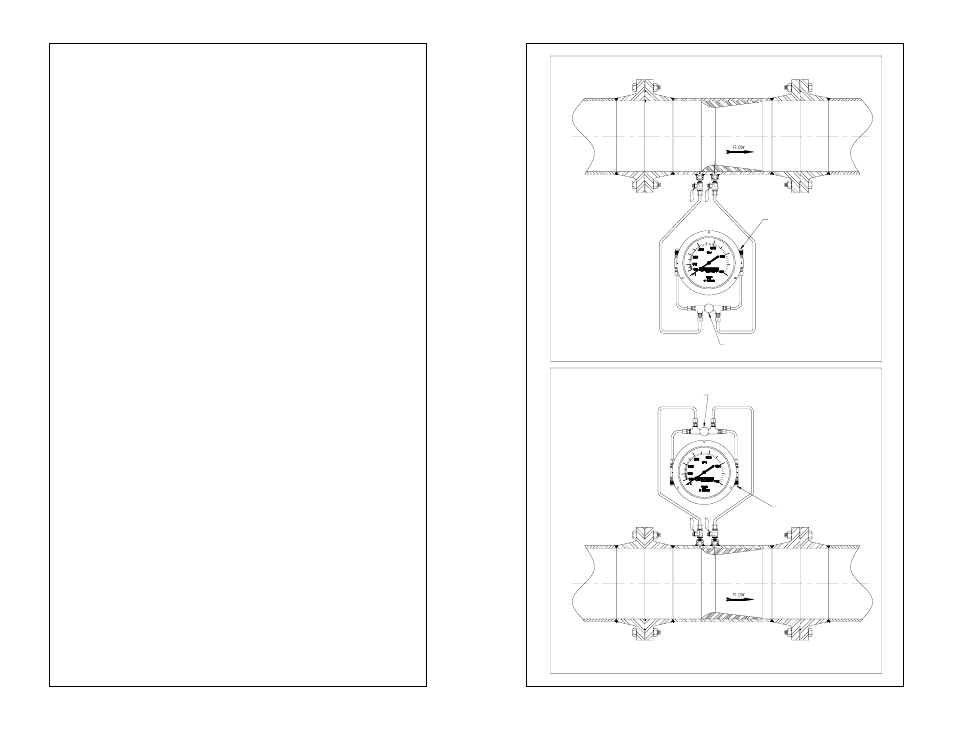

B. For liquid applications the GMD should be installed below the

primary element in a level position (see diagram 1).

If recommended mounting is not possible, care must be taken to

ensure that the gage is vented periodically.

C. For air/gas applications the GMD should be installed above the

primary element in a level position (see diagram 2).

Installation

A. The connecting tubing between the primary element and the

gage should be as short as possible and should slope a mini-

mum of 1 inch per foot.

B. Secure and support tubing to prevent sagging and or vibration.

C. Care must be taken to ensure that the head heights are even.

D. A Bleed line should be run from the GMD vent valves to a pan

or drain.

Operation

**Preso strongly recommends the use of a single valve bypass or a

3-valve manifold with the GMD gage**

A. Identify Hi and Lo pressure inlets on the GMD.

B. Ensure bypass valve is OPEN! If no bypass, extreme caution

must be used when opening Hi and Lo valves on the primary

element. The valves must be opened simultaneously to prevent

over pressurization and possible damage to the gage.

C. Connect GMD to corresponding Hi and Lo pressure taps of the

primary element (via 3-valve manifold, if being used).

D. Open Hi and Lo instrument valves on the primary element.

E. Alternately open the Hi and Lo vent valves to purge the lines.

F.

When venting is complete, close the bypass valve to begin

taking readings.

Maintenance

Normal operation requires no maintenance. In case of dirt or scale

build up flush meter with clean water or a compatible solvent.

>>> Contact your local representative if you have any <<<

>>> questions regarding PRESO products <<<

RECOMMENDED LIQUID INSTALLATION:

H

L

(DIAGRAM 1)

VENT VALVES

BYPASS VALVE

(DIAGRAM 2)

BYPASS VALVE

RECOMMENDED GAS INSTALLATION:

VENT VALVES

H

L