Installation instructions, single support, Flow – Badger Meter Model BAR User Manual

Page 5

User Manual

Page 5

April 2014

INSTALLATION INSTRUCTIONS, SINGLE SUPPORT

1 . Choose the proper location to install the BAR Ellipse using AGA/ASME standards (or equivalent) . See

2 . Grind the surface of the pipe where the BAR Ellipse is to be inserted to provide a clean area for welding .

3 . Weld the supplied thread-o-let to the pipe using standard codes for your application (1/16 in . weld gap recommended) .

Take care to protect the threads during the welding process .

4 . Drill a hole through the pipe wall according to

.

Pipe Size

Model/Sensor

Weld Connector

Drill Bit

2…5 in .

BAR (1/2 in .)

1/2 in .

5/8 in .

6…12 in .

BAR (7/8 in .)

1 in .

1-1/8 in .

14…24 in .

BAR (1-1/4 in .)

1-1/4 in .

1-3/8 in .

Table 2: Single support drill bit size

5 . De-burr the hole just drilled, especially on the inside of the pipe .

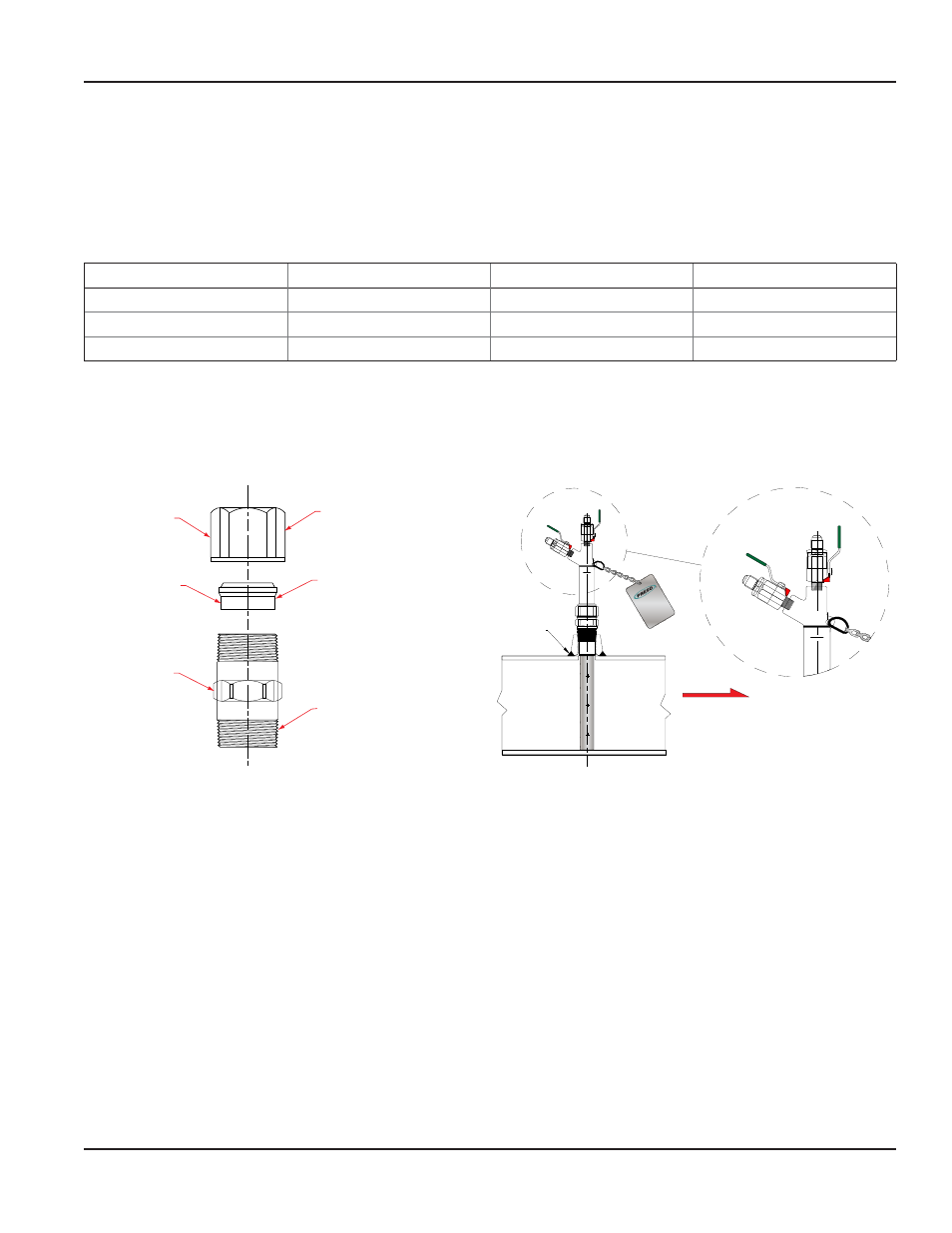

6 . Assemble the supplied compression fitting as shown in

. Thread the assembled compression fitting into the

thread-o-let manually . With a wrench, tighten the body of the fitting another 1-1/4 turns, being careful not to tighten the

compression nut .

Nut

Insert

Body

Thread nut loosely

onto body of the

compression fitting

Install insert

as shown

Install threaded

portion into weld

fitting on pipe

FLO

W M

ETE

RS

DEB

ITM

ETE

RS

MED

IDO

R D

E F

LUJ

O

FLOW

Field

Weld

H

L

H

L

Figure 4: Single support installation

7 . Install the instrument valves (optional) at the BAR Ellipse head connections . Make sure that the valves are fully closed to

prevent them from leaking during start-up .

8 . Insert the BAR Ellipse through the compression fitting . Carefully push the sensor into the pipe until it reaches the

opposite wall .

9 . While holding the BAR Ellipse in its fully inserted position, align the arrow on the sensor head with the direction of flow .

See

10 . Manually tighten the compression nut in order to prevent leakage, then use a wrench to tighten the compression nut

another 1-1/4 turns .