Badger Meter Series 310 Analog Transmitter User Manual

Page 3

3

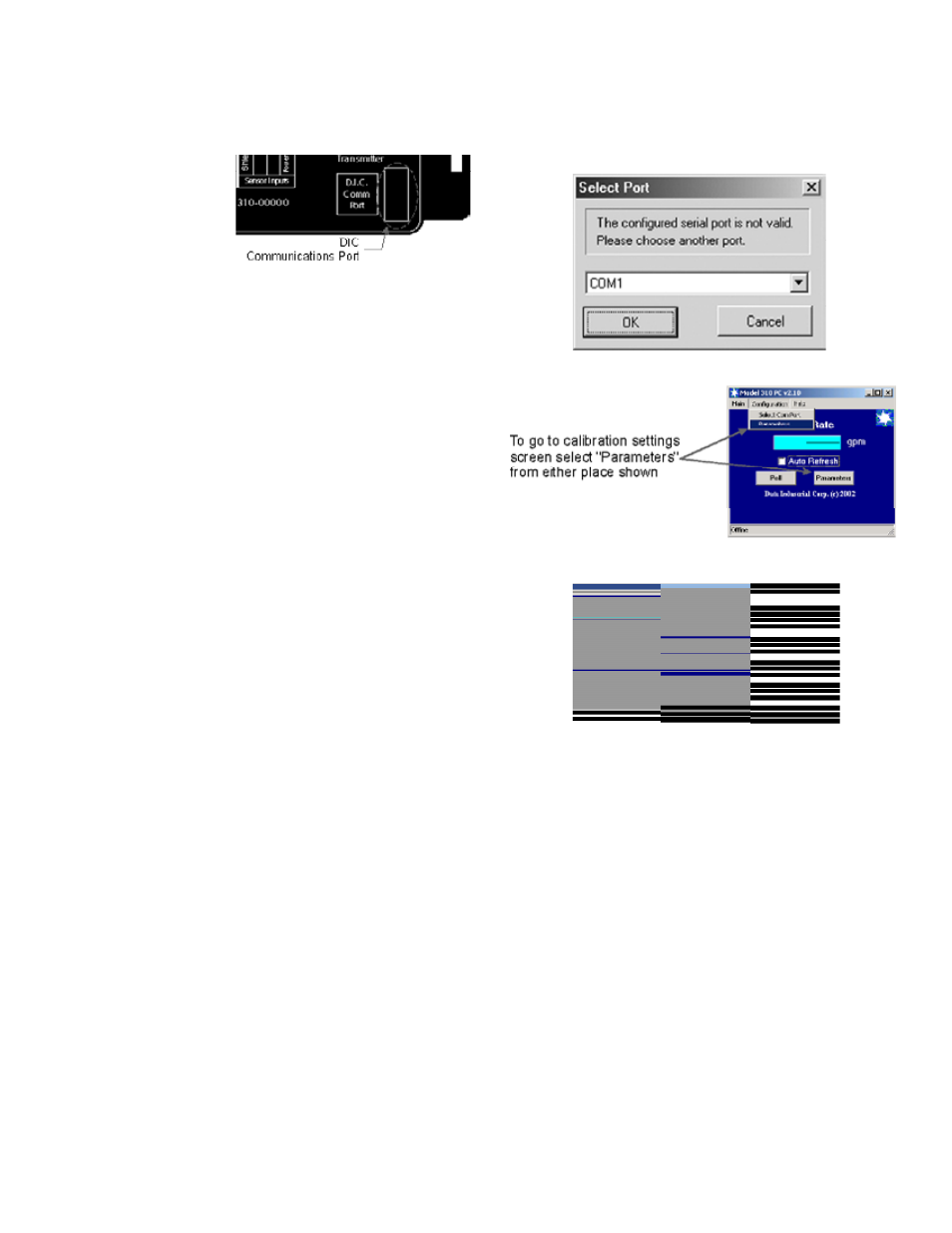

Location of the

DIC Communication Port

Communications cable wiring

Field calibration requires a Data Industrial A310 Pro-

gramming kit (consisting of a custom cable and soft-

ware) and a PC running Windows® 9x, ME, NT, 2000

or XP. In order to program the Model 310 it must be

connected to Loop-

Power and the A301

cable must be con-

nected between the

Model 310 Comm

port connector and an

available DB9 COM

port on a computer.

Note:

The Data Industrial A301 Cable will work with all 300

Series products. However the older version of the cable

(A300) does not have sufficient bandwidth to work with

the newer 340 Series Transmitters or SDI Flow Sen-

sors.

Data Industrial provides free programming software up-

dates via the Internet for all of 300 Series devices. Go

to www.dataindustrial.com for these updates.

Programming Software Installation

Floppy Installation

Place the software installation Disk 1 into the floppy

drive and run the setup.exe program to install.

CDROM Installation

Place the software CD into the CDROM drive and it

should autostart. Click programming software, then click

the Model 310 and the software installation will begin.

Web Installation

The Installation software can be found at the Data

Industrial web site (www.dataindustrial.com) in the sup-

port section.

Model 310 Programming

Programming the Model 310 is accomplished by install-

ing the Data Industrial programming software on a com-

puter and entering data on templates of the Windows®

based program.

1. Install the 310 PC Interface Software into the com-

puter.

2. Connect the computer to the Model 310 transmit-

ter using the Data Industrial A301 communications

cable. Plug A301 cable to the socket labeled “D.I.C

Comm Port” taking care to properly align the tab on the

plug and socket to maintain polarity then plug the DB9

connector of the Data Industrial A301 communications

cable to an avaliable PC com port that has the Model

310 software installed.

3. Connect the Model 310 transmitter to a powered

4-20mA loop. (if setting up in the office a 9-24VDC

power source can be used to simulate the loop).

4. Open the interface software and select the appro-

priate COM PORT as shown in the dialog box below.

5. Open the Parameters Screen as shown below.

6. Program using diagram below as a reference.

Note #1

Sdi - If the SDI sensor type is selected the required

K and offset values can be found the the SDI owners

manual.

4000 - If the 4000 sensor type is selected, click the

choose button and select the sensor from the pull down

box that appears.

Sine - Provided for connection to sensors which have a

sine wave output. Please consult sensor manufacturer

for the calibration settings.

200 Insert Type - If the 200 Insert Sensor type is

selected the required K and offset can be found the

the 200 owners manual or if the manual is not handy

the calculate button can be pushed and an inside pipe

diameter can be entered and once calculate is pressed

a K and offset will automatically be entered in.

200 Tee Type - If the 200 tee type is selected, click the

choose button and select the sensor from the pull down

box that appears.