Maintenance, Part number information, Troubleshooting guide – Badger Meter Converters User Manual

Page 10: Maintenance 10, Part number information 10, Troubleshooting guide 10

MAINTENANCE

1 Frequent inspection should be made A schedule for maintenance checks should be determined by the environment and

frequency of use It is recommended that it should be inspected at least once a year

2 Perform visual, electrical and mechanical checks on all components on a regular basis

a Visually check for undue heating evidenced by discoloration of wires or other components, damaged or worn parts, or

leakage evidenced by water or corrosion in the interior

b Electrically check to make sure that all connections are clean and tight, and that the device is operating correctly

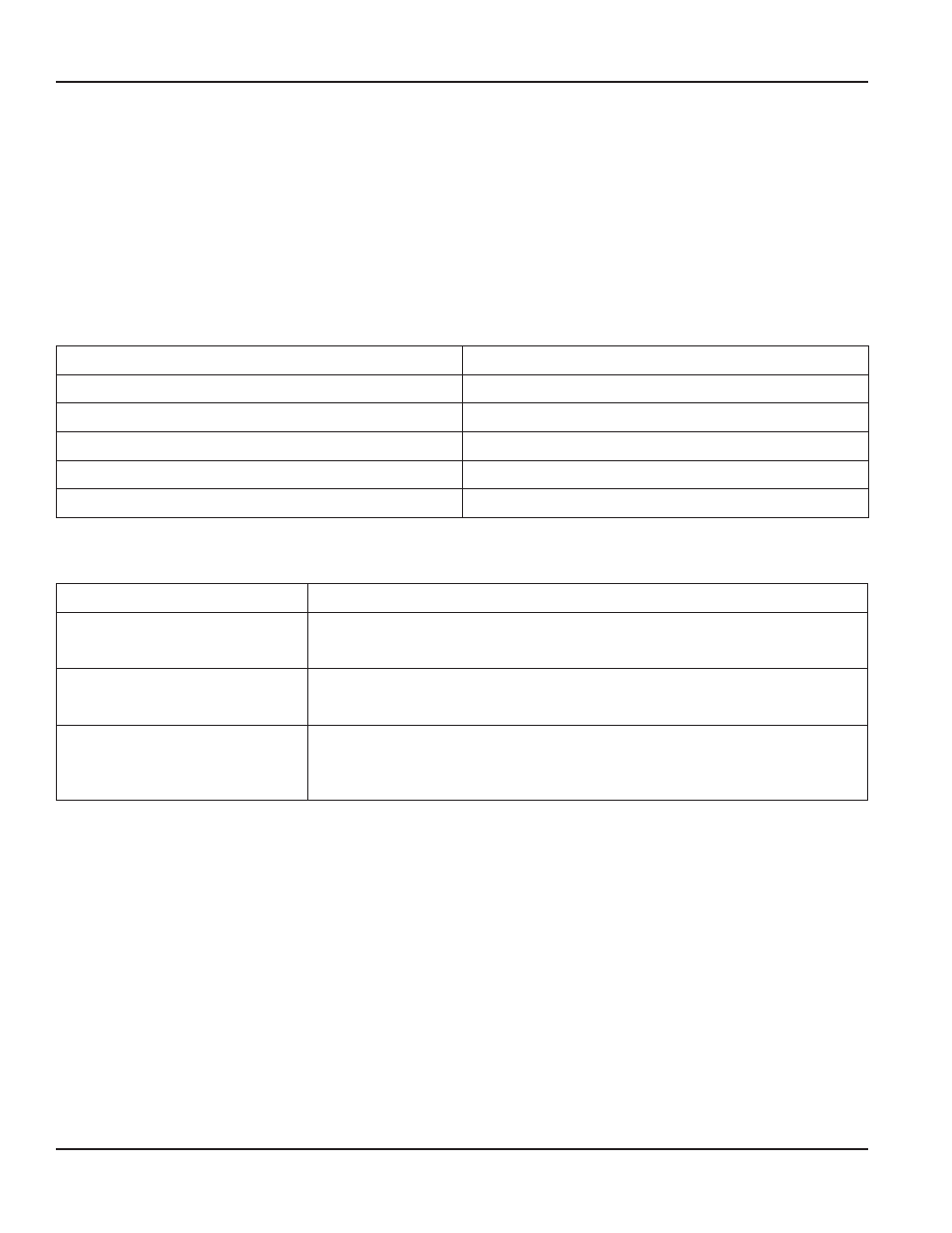

PART NUMBER INFORMATION

Description

Part Number

Aluminum “Y” enclosure

B220239

Pickup cable

B222-120

Complete programming package

B220-954

F to I device only

B220803

F to V device only

B220806

TROUBLESHOOTING GUIDE

Trouble

Remedy

No current output

• Check polarity of the current loop connections for proper orientation

• Make sure receiving device is configured to provide loop current

Analog output reads a constant

reading

• Make sure there is flow in the system

• Verify that the rotor inside the turbine meter turns freely

Analog output is not stable

• External noise is being picked up by the sensor Keep all AC wires separate from

DC wires

• Check for radio antenna in close proximity This usually indicates a weak signal

Signal Conditioner, Intelligent Frequency Converter

Page 10

November 2013