Badger Meter Recordall Compound Series Meters User Manual

Page 9

UPSTREAM AND DOWNSTREAM VALVES MUST BE CLOSED BEFORE ATTEMPTING TO REMOVE METER HEAD OR

COVER FROM HOUSING OR PERFORMING ANY SERVICE/MAINTENANCE REQUIRING DISASSEMBLY. FAILURE TO

DO SO CAN LEAD TO HEAD OR COVER BEING "EJECTED" FROM HOUSING, CAUSING PERSONAL INJURY AND/OR

PROPERTY DAMAGE!

1 . Loosen each of the head or cover bolts about one and one- half turns . Do not completely remove the bolts .

2 . If the O-ring between the meter head/cover and the housing is secure and not leaking, pry the measuring element

assembly loose by inserting a screwdriver blade where the head and housing join together .

BE SURE THAT ANY WATER COMING OUT OF THE METER HEAD DOES NOT SPRAY ONTO ELECTRICAL EQUIPMENT TO

CREATE A SHOCK HAZARD.

3 . Allow the meter to drain and relieve internal pressure .

4 . When pressure is relieved, remove the head bolts . Lift the measuring element assembly from the housing .

For specific maintenance of the Turbo Head, see the Recordall Turbo Series Meter User Manual .

5 . When service is complete, start up the system as noted in

“Performance Checks and System Startup” on page 7

Check Valve

Periodic preventive check valve maintenance is highly recommended and should be practiced according to schedule to

assure continuous accuracy and trouble-free performance of your check valve . The valve is water lubricated and should be

regularly inspected for corrosion, obstructions in the waterways and for freedom of movement for all working parts . The

frequency of the inspections is dependent upon the quality of the water supply and authority having jurisdiction . Make sure

all equipment is adequately protected to prevent freezing and physical damage . Repair all leaks .

To remove or replace the knuckle joint assembly, follow these steps:

1 . Shut down the water system and lock it out, if possible .

2 . Loosen the vent screw in the lid slowly to relieve system pressure .

3 . Loosen and remove all inspection port bolts and remove the lid and gasket from valve .

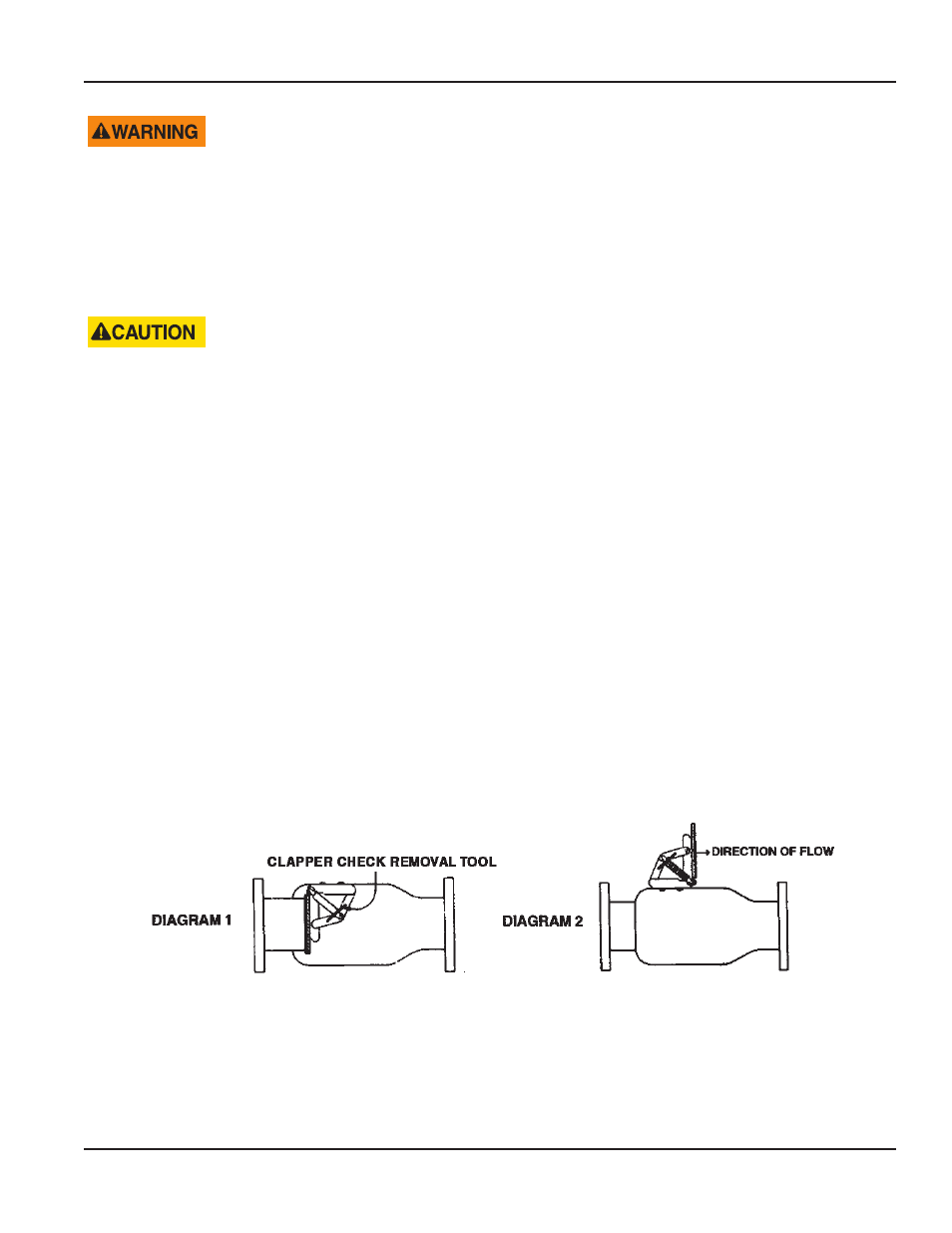

4 . Install proper size clapper check removal tool (see diagram 1 in

and Item 10 in

) . Be sure tool is pushed

to within 1/2" of linkage .

Figure 3: Clapper check removal tool

5 . Loosen equally the two knuckle joint mounting bolts until assembly is free . As bolts are loosened, the linkage will

release slightly and lock the clapper retainer tool in place .

6 . Remove the knuckle joint from the body assuring the clapper retainer tool is not disturbed, as the preloaded knuckle

joint springs have considerable tension in this position .

7 . Bolt the knuckle joint to the outside of the body using the new 3/8" bolts supplied with the new knuckle joint (see

diagram 2) .

User Manual

Page 9

October 2013