Amerex 05606 User Manual

Page 9

8

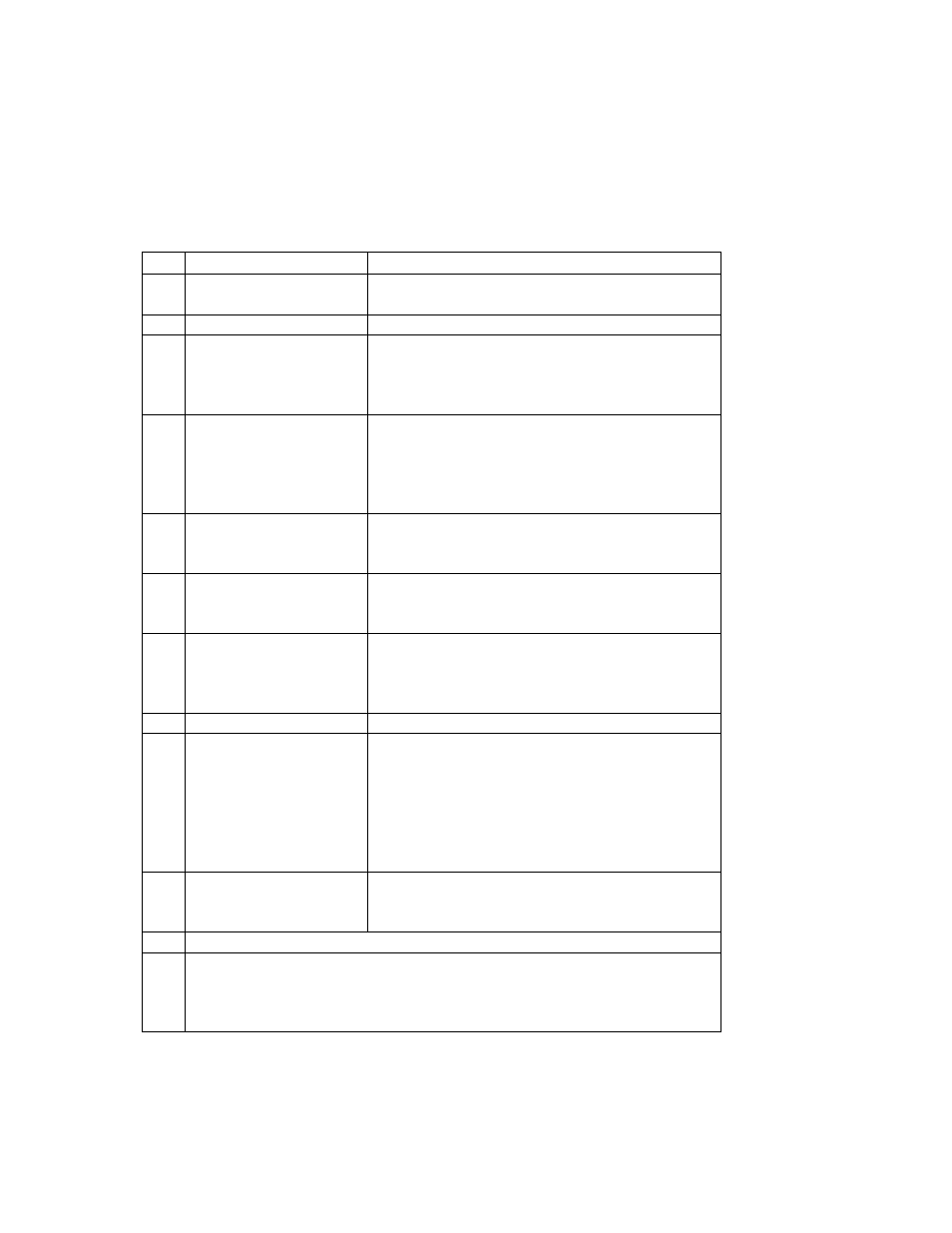

TROUBLESHOOTING GUIDE

WARNING:

Before attempting to correct any leakage problem, be sure that the agent

cylinder and hose are completely depressurized. Check to determine the

source of a leak before the extinguisher is depressurized. Leakage repairs

will require depressurization and removal of the valve assembly. Use Getz

HR-1 or other approved recharge/recovery system to depressurize

extinguisher.

PROBLEM

CORRECTIVE ACTION

1.

Pressure gauge

reads high or low

Temperature may have affected pressure

–

see temperature/pressure relationship chart.

2.

Leak through valve

Remove valve assembly, downtube, spring

and valve stem assembly. Install new valve

stem assembly. Check valve seat for

scratches or foreign matter.

3.

Leak at collar o-ring

Remove valve assembly, clean collar o-ring

seating surface thoroughly and lubricate

lightly with V-711 or equivalent. Install a

new collar o-ring after lubricating with V-711

or equivalent.

4.

Leak around gauge

threads

Remove gauge*, and install a new Halon

1211 gauge (see parts list) using Teflon

tape on the gauge threads.

5.

Defective gauge

Remove defective gauge* an install a new

Halon 1211 gauge (see parts list) using

Teflon tape on the gauge threads.

6.

Visible deterioration

of discharge hose

Replace hose assembly. Extinguishing

agent has been stored in hose for a

prolonged time. see Caution in Shut-Down

procedures

MODEL 600 ONLY

1.

Leak at safety disc

assembly

Inspect safety outlet for tightness or

damage. If loose, remove entire assembly

and reinstall using Teflon tape on the

threads. If damaged, replace with new P/N

03787 Safety Disc Assembly using Teflon

tape on the threads. Tighten only the large

hex nut.

2.

Agent level gauge

not functioning (if so

equipped)

Remove agent level gauge and discard.

Replace agent level gauge with Amerex P/N

06370

* Pressure gauge threads are coated with a special epoxy at the

factory. For easy removal, soak the valve assembly in hot water

(180°F/82°C) for two to four minutes. Remove gauge with a 7/16"

open end wrench.