Table 2: dimensions & weights – Advanced Protection HPS User Manual

Page 4

4

PRE-INSTALLATION & INSTALLATION PLANNING

Operating Environment

The standard unit uses a Type 1/12/3R/4 enclosure. Non-

metallic polycarbonate 4X, stainless steel and Type 1 flush

mount or pull box enclosures are available as options.

Before installing, ensure that your enclosure type and

application are appropriate per NEMA 250 with regard

to moisture, dirt, excessive dust, flammable materials or

atmospheres, corrosive vapors, etc. Please consult factory

if enclosure needs to be changed.

This SPD is designed in an ambient temperature range

of -40°C (-40°F) to +60°C (+140°F) with a relative

humidity of 0% to 95% (non-condensing). Excessive

temperature may inadvertently operate internal thermal

overtemperature protectors.

Load Side Installation

HP and HPS SPDs are tested and qualified as Type 2

SPDs per UL 1449 Third Edition and 2008 NEC

®

. These

SPDs are intended for load side installation of the service

overcurrent device per 2008 NEC

®

285.

When connected on load side of main disconnect, we

suggest connecting via a 60A circuit breaker. The circuit

breaker is the intended disconnect switch and provides

short circuit protection to the connecting conductors. The

HP and HPS families have internal overload protection

elements within the product. A breaker or disconnect is

not required for the SPD’s overcurrent protection. HP

and HPS SPDs have demonstrated 200kA Short Circuit

Current Ratings (SCCR). Confer to label on unit.

Audible Noise

SPD background noise is negligible or non-existent, and

does not restrict the location of installation.

Mounting, Dimensions, and Weight

The HP and HPS series include enclosures and are

intended for wall mounting. (The XTE/HP and XTE/HPS

are component SPDs intended for installation within other

electrical gear already having enclosures.)

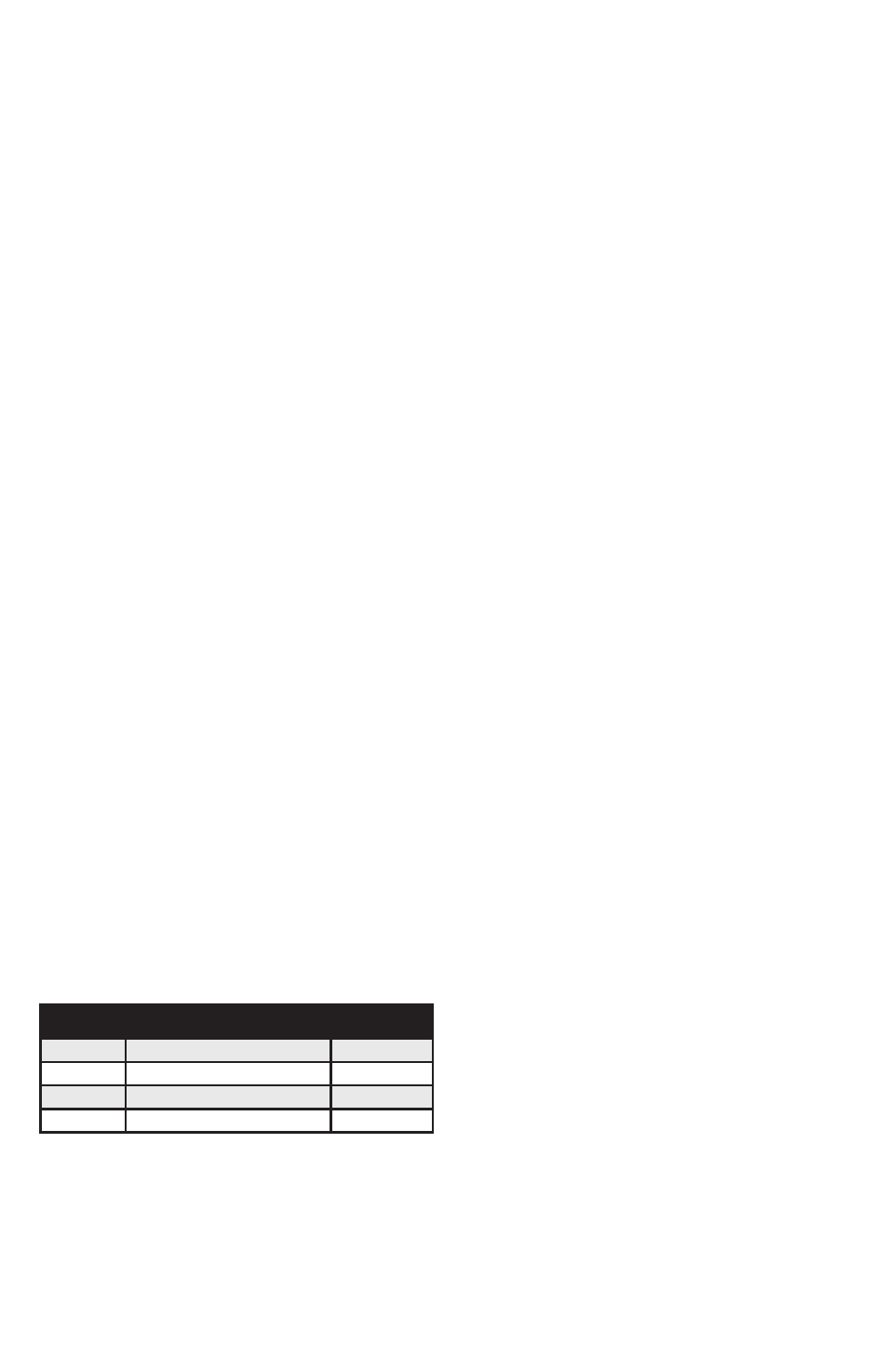

This SPD is designed to be wall mounted. The standard

enclosure is: 12” x 12” x 6” (L/W/D), and the weight is 25

lbs. The XTE Series is designed for internal mounting in the

electrical distribution equipment. Standard backplane size

is: 10.75” x 10.88” x 4.5”, and the weight is 61 lbs. (Verify &

check numbers). See Table 2 below.

Table 2: DIMENSIONS & WEIGHTS

HP

H/W/D (in. / mm.)

Weight

Standard

12"x12"x6" (305x305x152)

25 lbs (11.3 kg)

HPS

H/W/D (in. / mm.)

Weight

Standard

12"x12"x6" (305x305x152)

25 lbs (11.3 kg)

Lead Lengths & Maximizing SPD Performance

SPD’s must be located as close to the circuit as possible

to minimize parasitic losses. Surges are high current, high

frequency events that cause substantial voltage drops

across conductors. This hurts SPD performance. Use the

shortest & straightest possible leads. Pre-Plan installations

and ensure that nearest breaker positions are used. If new

construction, adjust breaker locations as appropriate.

Tip: Voltage drops for normal 120V or 277V lines might be 2-3V

per hundred feet. In surge applications, voltage drops might

be 100-150V per foot. These voltage drops add to clamping

voltage, thus hurting performance. Make every effort to keep

leads short and straight. As distribution gear becomes larger,

shorter leads are more difficult to accomplish. When longer

leads are unavoidable, gently twist leads together (one to two

twists per foot), or tie-wrap leads together.

Tip: surges create magnetic fields per the ‘right-hand rule’.

When current goes in direction of thumb, magnetic field is

in direction of curl of fingers. As surge current goes to SPD,

fields are created in one direction. When the SPD sends those

currents to neutral and/or ground, current goes in the opposite

direction. If ‘coming & going’ are on the same axis, the magnetic

fields can be cancelled, thus avoiding performance decrease.

Gentle twists, bundling & tie-wraps accomplish this.

Shortest Leads Possible

▪

Leads must be as short and straight as possible -

See NEC

®

Art. 285.12

▪

Pretend wire is $1000 per foot coming out of your pocket.

▪

No long leads

▪

No sharp bends

▪

No wire nuts

▪

How short is short enough? As short as you can make it.

▪

How long is too long? If anyone else can make it shorter.

Overcurrent Protection

SPDs draw very little current under normal conditions and

conduct for a brief duration upon encountering a transient

surge current. This SPD contain internal overcurrent and

overtemperature protection to protect against abnormal

voltage conditions.

Supplemental overcurrent protection is not required to protect

this SPD. However, connecting conductors require protection

in Type 2 or 4 applications. Follow applicable codes.

Voltage Rating

Before installing SPD, verify that it has the same voltage

rating as the power distribution system. Compare the SPD’s

nameplate voltage or model number and ensure that SPD

configuration matches the intended power source. See Table 1.

The specifier or the user of the device should be familiar with the

configuration and arrangement of the power distribution system

in which any SPD is to be installed. The system configuration

of any power distribution system is based strictly on how the

secondary windings of the transformer supplying the service

entrance main or load are configured. This includes whether

or not the transformer windings are referenced to earth via a

grounding conductor. The system configuration is not based on

how any specific load or equipment is connected to a particular

power distribution system.

480V System Example: SPDs should be installed per the

electrical system, not per a load or motor’s wiring connection.

For example, a 480V three phase motor might appear to be

connected as a 480V Delta. In actuality, the serving distribution

system might be a 480Y/277V grounded Wye, with or without

a neutral pulled to the motor or MCC. The system is still a

480Y/277V Wye, even though the load is connected as a

Delta. A grounded Wye has a defined reference to ground

(i.e., neutral is bonded to ground). Some Delta systems are

ungrounded, which have no reference to ground and are known

to become unstable in certain situations. Such instability can

cause line to ground voltage fluctuations that may prematurely

fail SPDs. For this reason, the NEC

®

Article 285 has placed

SPD restrictions on ungrounded systems. As generalizations,