Dimensions & weights, Internal configurations vs max temp – Warren Controls 3800 Series E-BALL ROTARY CONTROL VALVES User Manual

Page 7

7

Series 3800 3800_IOM_RevB_0513

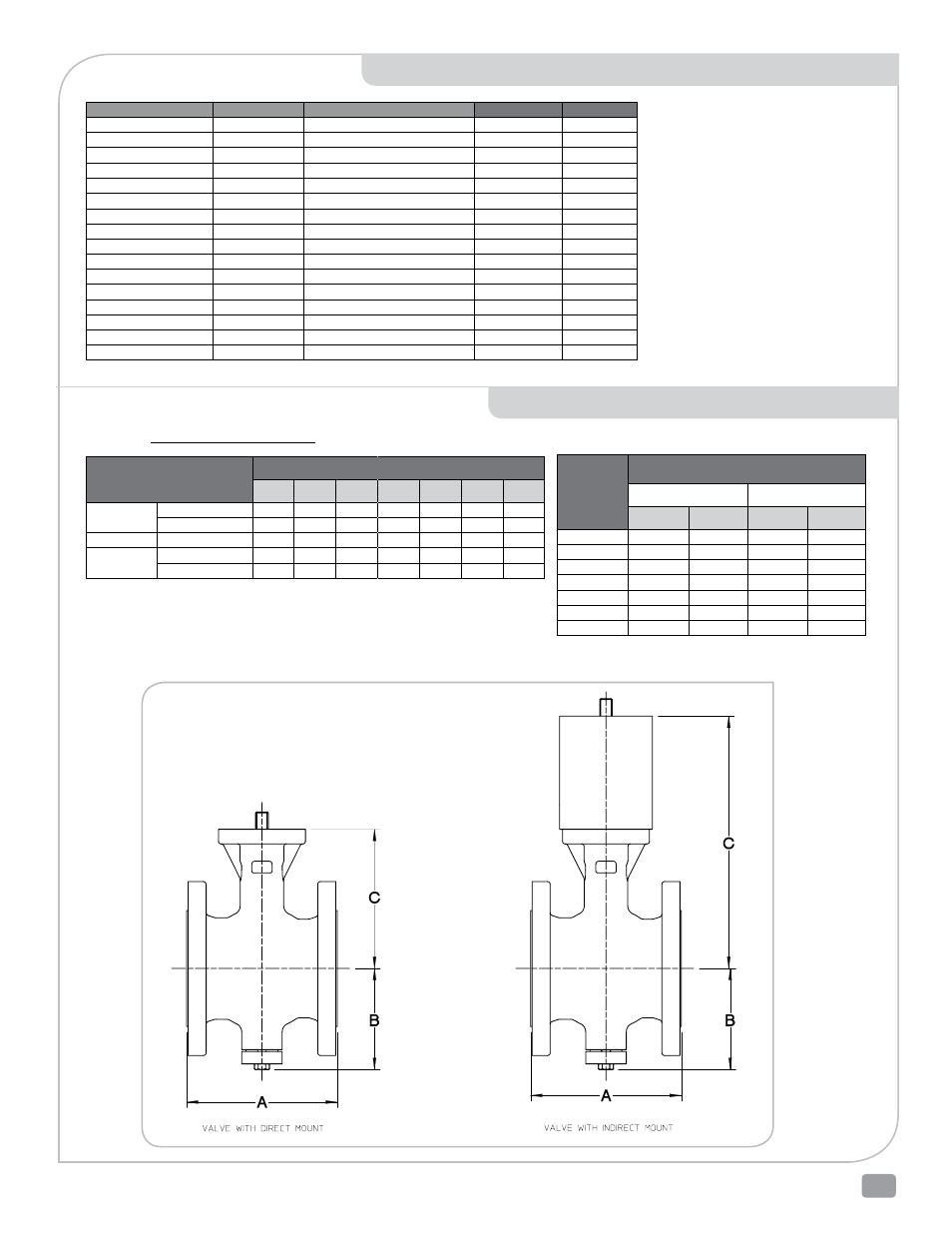

DIMENSIONS & WEIghTS

DIMENSION (IN)

VALVE SIzE (IN)

1

1-1/2

2

3

4

6

8

A

150FLG

4

4-1/2 4-7/8 6-1/2 7-5/8

9

9-5/8

300FLG

4

4-1/2 4-7/8 6-1/2 7-5/8

9

9-5/8

B

2-7/8 3-1/4 3-5/8 4-1/2 5-3/8 6-5/8 7-3/4

C

DIRECT MTG

4-3/4

5

5-1/8 6-1/8 7-1/8 8-5/8 10-1/8

INDIRECT MTG

9-5/8 9-7/8

10

11

14

15-1/2

17

VALVE

SIzE

(IN)

WEIghT (LB)

DIRECT MTG

INDIRECT MTG

150FLG

300FLG

150FLG

300FLG

1

20

22

29

31

1-1/2

23

30

32

39

2

20

25

29

34

3

35

50

44

59

4

55

80

76

101

6

100

140

121

161

8

145

200

166

221

FACE TO FACE DIMENSIONS CONFORM TO ANSI/ISA S75.04

ACTUAL SHIPPING WEIGHTS MAY VARY

(See also Flange Sizes and Patterns section in the Series 3800 Product Specifiction)

1

For Maximum Temperatures see also

Valve Body Pressure-Temperature

Ratings and Actuator Temperature

Ratings

Trim Material

Shaft Design

Bearing & Seals

Packing

Max Temp

1

S 316 Stainless Steel

C Thru Direct

S PEEK

T Teflon V-ring 450°F

Z TTZ Ceramic

D Thru Indirect T PEEK w/ Fluoraz 797 Seal

T TFE Soft Seats

E Split Direct

P PEEK Soft Seats

F Split Indirect

6 Alloy 6

S 316 Stainless Steel

D Thru Indirect S PEEK

J Graphite

450°F

Z TTZ Ceramic

F Split Indirect

T PEEK w/ Fluoraz 797 Seal

A Teflon V-ring

T TFE Soft Seats

P PEEK Soft Seats

6 Alloy 6

S 316 Stainless Steel

D Thru Indirect Y Alloy 6B w/ Fluoraz 797 Seal

G Graphite

500°F

Z TTZ Ceramic

F Split Indirect

6 Alloy 6

S 316 Stainless Steel

D Thru Indirect 6 Alloy 6B

G Graphite

800°F

Z TTZ Ceramic

F Split Indirect

6 Alloy 6

INTERNAL CONFIgURATIONS VS MAx TEMP