Installation guidelines – Warren Controls 377 Float Cage User Manual

Page 5

5

Level COntrols - IOM 377 Float Cage/326L & 322L Lever Valves 377_326L_322L_IOM_RevAa1112

dImEnSIon L - rISIng LEVEr oPEnS VALVE

iNSTALLATiON GUiDELiNES

bEForE you bEgIn

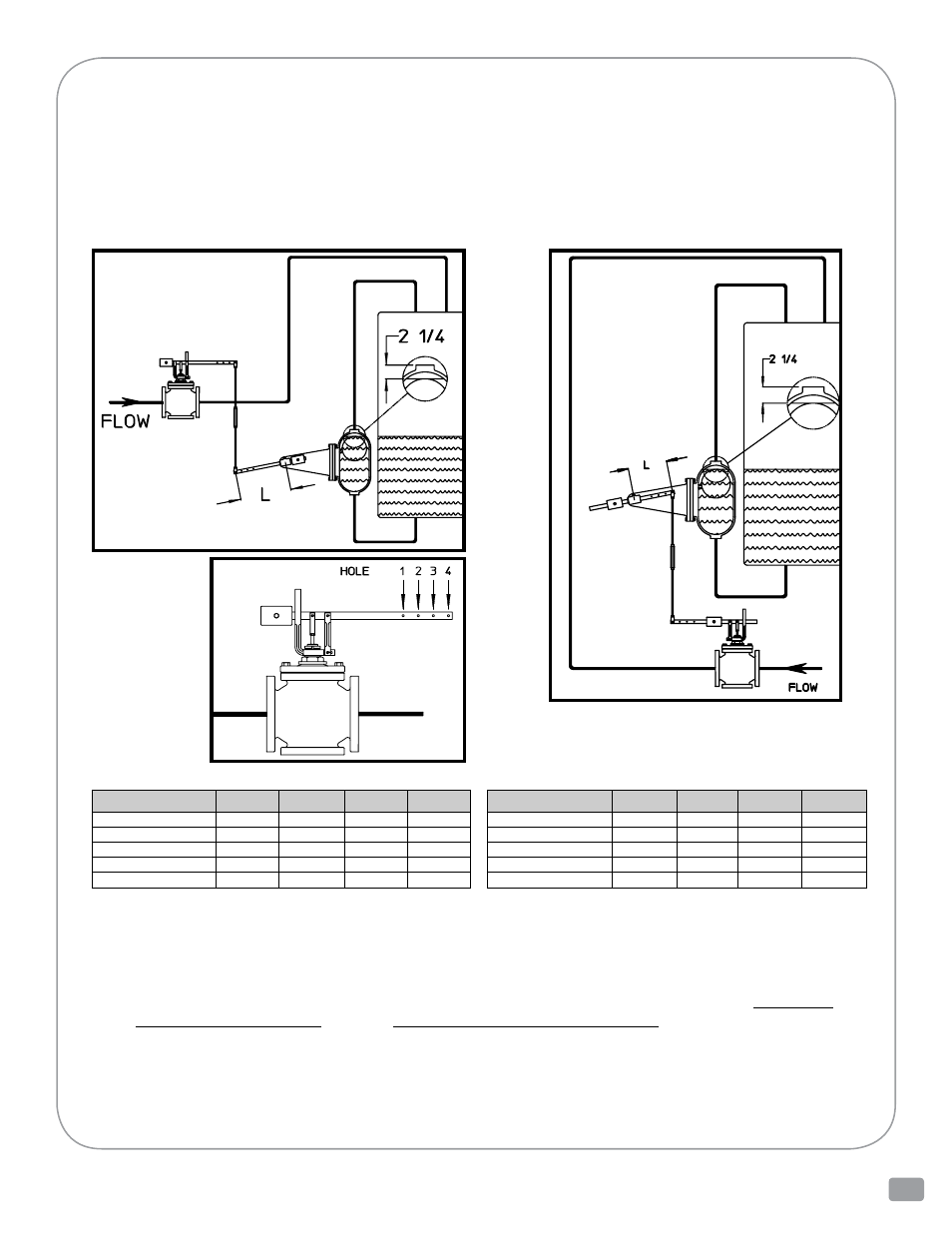

The guidelines presented here are for a typical tank filling application utilizing a 377 Float Cage and a Warren

Controls Lever Valve. As shown in the Typical Installation drawings the 377 closes the Lever Valve when the

water in the tank reaches the desired level. Since there are numerous possible working configurations it is nec-

essary for you to determine where the 377 and Lever Valve will be located before you install them. The InSTAL-

LATIon guIdELInES are presented for this purpose. Please read all guidelines thoroughly before you begin

The 377 when installed according to these guidelines will provide a maximum water level in the tank that is

2-1/4 inches below the top of the 377. The 377 Float Cage must be installed with the axis through the 1-1/2 nPT

pipe connections oriented vertically. The 326L or 322L Lever Valve is located above the 377 in rising lever opens

valve applications, and below the 377 in rising lever closes valve applications. The lever valve must be installed

with the fluid flowing in the correct direction. For proper operation in all applications, lever valves must be

piped according to the corresponding flow arrows, or inlet markings present on each valve (See Information

Present on 326L Lever Valves section or Information Present on 322L Lever Valves section for location of im-

portant information on valve). The lever valve must be installed in the vertical position with the stem pointing

upward. When the maximum desired water level in the tank is reached the 377 closes the lever valve stopping

the flow of water into the tank. When the lever valve is closed its lever is horizontal, the turnbuckle is vertical, the

end of the 377 lever connected to the turnbuckle is at its lowest point in rising lever opens valve applications

and at its highest point in rising lever closes valve applications. Clearance must be allowed for each turnbuckle

connection and lever rotation. There are four possible turnbuckle connecting holes on the lever.

rISIng LEVEr oPEnS VALVE dIAgrAm

rISIng LEVEr CLoSES VALVE dIAgrAm

TurnbuCkLE

ConnECTIng

hoLE

dIAgrAm

dImEnSIon L - rISIng LEVEr CLoSES VALVE

VALVE

HOLE 1

HOLE 2

HOLE 3

HOLE 4

1/2, 3/4 & 1 IN 326L

9

10-1/4

11-3/4

13-1/4

1-1/4 & 1-1/2 IN 326L

13

15-1/4

17-1/2

19-3/4

2 IN 326L

16

18-1/2

21-1/4

NA

1-1/2 & 2 IN 322L

7-1/2

8-3/4

10

11-1/4

2-1/2 & 3 IN 322L

11-1/4

13-1/4

15

17

VALVE

HOLE 1

HOLE 2

HOLE 3

HOLE 4

1/2, 3/4 & 1 IN 326L

7-1/2

9

10-1/4

11-3/4

1-1/4 & 1-1/2 IN 326L

11

13

15-1/4

17-1/2

2 IN 326L

13-1/4

16

18-1/2

21-1/4

1-1/2 & 2 IN 322L

6-1/4

7-1/2

8-3/4

10

2-1/2 & 3 IN 322L

9-1/2

11-1/4

13-1/4

15