8a 8b – American Standard 2100 User Manual

Page 2

7 3 0 4 8 1 - 1 0 0 R e v . C

6

7

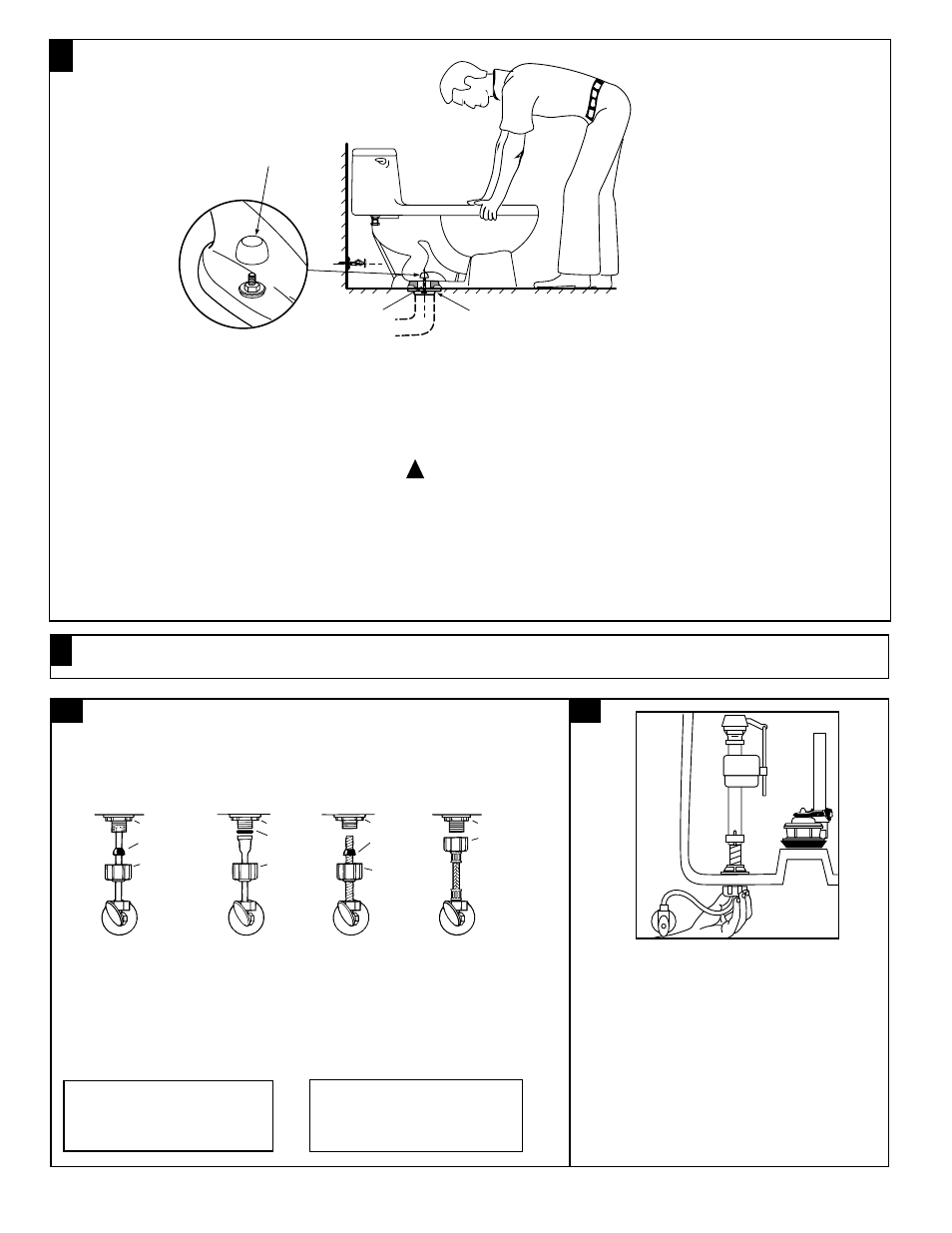

INSTALL TOILET

a.

Position toilet squarely to wall and, with a rocking

motion, press bowl down fully on wax ring and flange.

Alternately tighten nuts until toilet is firmly seated on

floor.

CAUTION:

DO NOT OVERTIGHTEN NUTS

OR BASE MAY BE DAMAGED!

b.

Install caps on washers. (If necessary, cut bolt height

to size before installing caps.)

c.

Smooth off the bead of sealant around base. Remove

excess sealant.

INSTALL TOILET SEAT Install toilet seat in accordance with manufacturer's directions.

!

- 2 -

8a

8b

Before continuing, determine the type of water supply connecation you have from

the chart below and use the appropriate assembly parts required to properly

reconnect the water supply. DO NOT use plumber's putty to seal these fittings.

CAUTION: DO NOT USE

CONE WASHER WITH

PLASTIC SUPPLY LINE.

These parts must be used as

illustrated to insure water-tight

connection. Use of existing

coupling nut may result in

water leakage. Water supply

tube or pipe must extend at

least 1/2" inside threaded

shank of valve (does not apply

to flanged tubing).

Use existing

coupling nut

and washer.

Use existing spiral

cone washer.

Fluidmaster cone

washer may not

seal completely on

spiral type supply

line.

Captive cone

washers already

included. No

additional washers

needed.

CAUTION: Overtightening of

LOCK NUT or COUPLING NUT

could result in breakage and

potential flooding.

METAL/COPPER

FLARED TUBING

METAL FLANGED

TUBING

METAL SPIRAL

TUBING

VINYL/BRAIDED

CONNECTOR

LOCK NUT

LOCK NUT

LOCK NUT

LOCK NUT

COUPLING

NUT

COUPLING

NUT

EXISTING

COUPLING

NUT

COUPLING

NUT

WATER

SHUT-OFF

WATER

SHUT-OFF

WATER

SHUT-OFF

WATER

SHUT-OFF

CONE

WASHER

EXISTING

CONE

WASHER

EXISTING

WASHER

With correct washers in place

(see Step 8a), tighten

COUPLING NUT 1/4 turn beyond

hand tight. DO NOT

OVERTIGHTEN.

BOLTS

CLOSET FLANGE

BOLT CAP