Ar ch ive d – Seametrics EX80 Series v.1 User Manual

Page 7

Page 5

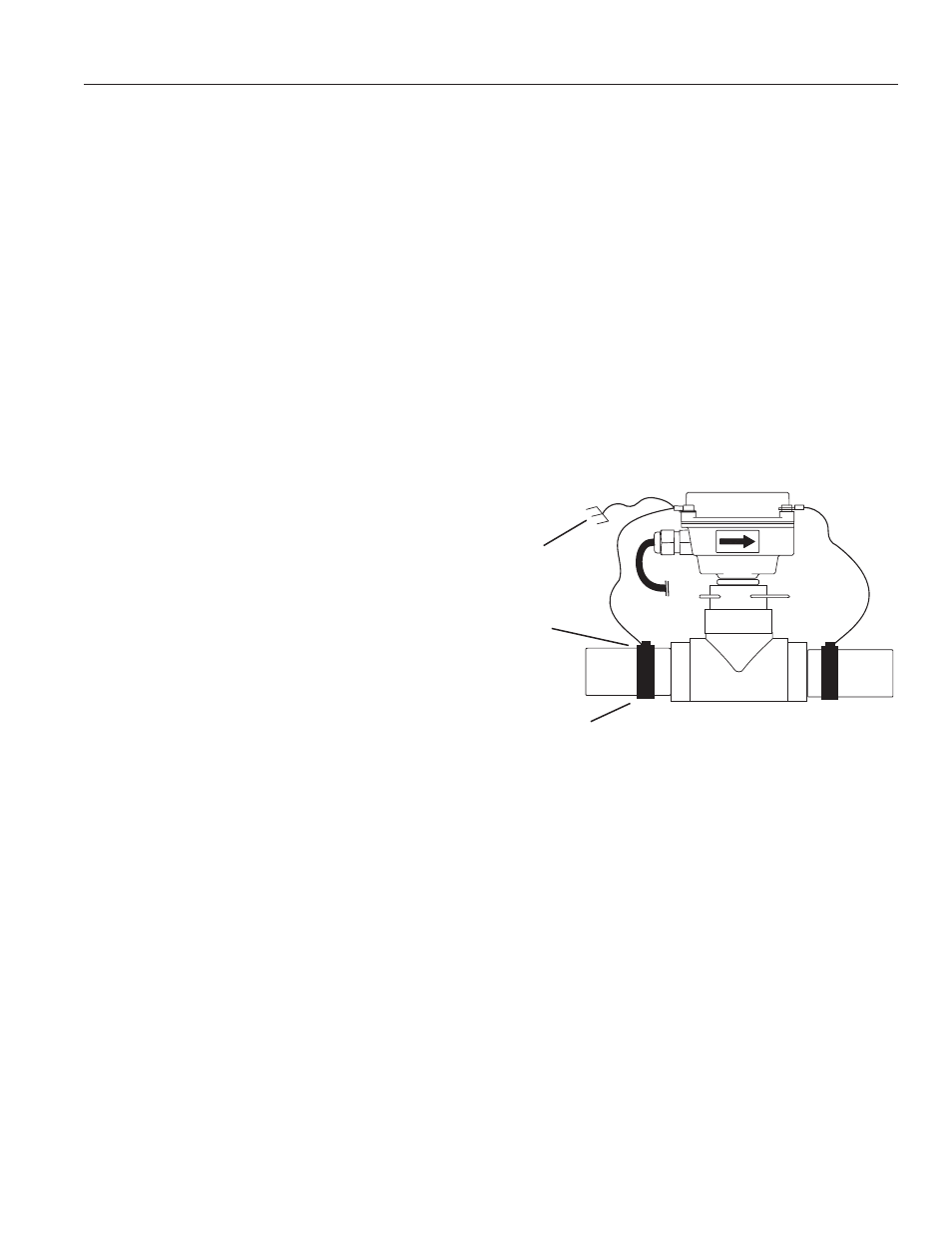

Grounding Guidelines:

•

For best results, use a good quality ear th ground,

such as metallic water piping, or a stake driven

into the ground.

•

If the flow sensor is installed in metallic piping, for

optimum grounding clamp wires to the piping a

shor t distance to either side of the flow sensor

using hose-type clamps. Connect these wires to

the earth ground and to one of the housing screws.

General Electrical Guidelines:

•

Whenever possible avoid running control cables

in the same conduit with AC power. Use shielded

control cable where this type of installation is

necessar y.

•

If using shielded cable, be sure that one end is

grounded

•

Avoid routing flow sensor cables in close proximity

to a variable frequency drive.

•

Recommended power and output wiring is 18-22

AWG control cable, shielded if the run length is

more than 18 feet (6 meters).

•

Recommended voltage is 12-24 VDC. Note that

unregulated power supplies can var y from

nameplate voltage by a considerable amount.

When in doubt, use a regulated power supply.

See the Connections diagrams on the following pages, for

the appropriate terminals.

Power: A 12 - 24 Vdc power supply which is capable of

at least 250 mA current output is needed.

Pulse Output: This open-collector isolated output does

not supply power. It functions like a polarity-sensitive switch

closure. It reaches a maximum of 500 Hz at the maximum

flow rate of 20 feet/second. This pulse is generated in

both for ward and reverse flow directions (see “Direction”

below).

Note: This output is limited to 5 mA at 30 Vdc

maximum.

Direction Indicator: This output is switched by a solid

state relay, which is not polarity sensitive. It is “off” (open)

when flow is in the for ward direction and “on” (closed)

when flow is in the reverse direction.

Note: this output is

limited to 100 mA at 150 Vdc maximum.

ELECTRICAL CONNECTIONS

GROUNDING DIAGRAM

Ground To

Metallic Pipe

Earth

Ground

Hose Clamp

AR

CH

IVE

D

(Includes Dates 6/14/04 to 5/05)