Caution: clip(s) must be installed before use – Seametrics IP800-Series User Manual

Page 3

GENERAL INFORMATION

The IP800-Series are impeller (or “paddlewheel”) insertion me-

ters designed for use with a wide variety of liquids in pipe sizes

1/2" to 8". Sensors are available in brass, 316 stainless steel,

PVC, and polypropylene. Bodies are machined from a solid rod

for maximum precision. High-quality jewel bearings and nickel-

bound tungsten carbide shafts are used for extreme low friction

and long life. Low-flow performance is good, although other

Seametrics flow meters are recommended where extremely low

flows are being measured.

The rotation of the rotor is detected by a non-drag Hall-effect

sensor. Output is a current-sinking pulse (square wave), which

can be sent long distances (up to 2,000 feet) without a trans-

mitter. This signal can be connected directly to PLC's, counters,

and computer cards, as well as a variety of Seametrics controls

and displays.

Seametrics IP meters are ideal for chemical proportioning ap-

plications. If no display is required, a simple divider such as

the PD10 provides adjustable pump pacing. For rate and total

display, the FT415 (battery powered) or FT420 (loop powered)

flow indicator can be mounted directly on the IP800-Series

meter, or remotely on a wall or panel. The AO55 blind analog

transmitter can be used to convert to a 4-20 mA output. IP

meters are also compatible with the DL76 data logger and

FT520 batch processor.

The IP800-Series require special fittings that ensure correct

depth placement in the pipe. Fittings come in a variety of ma-

terials for compatibility with specific applications. Tee fittings

are individually wet-calibrated at the factory and marked with

the K-factor (pulses per gallon). Saddle fittings must be field-

installed on the pipe and do not come wet-calibrated. K-factors

for saddles are based on factory-testing.

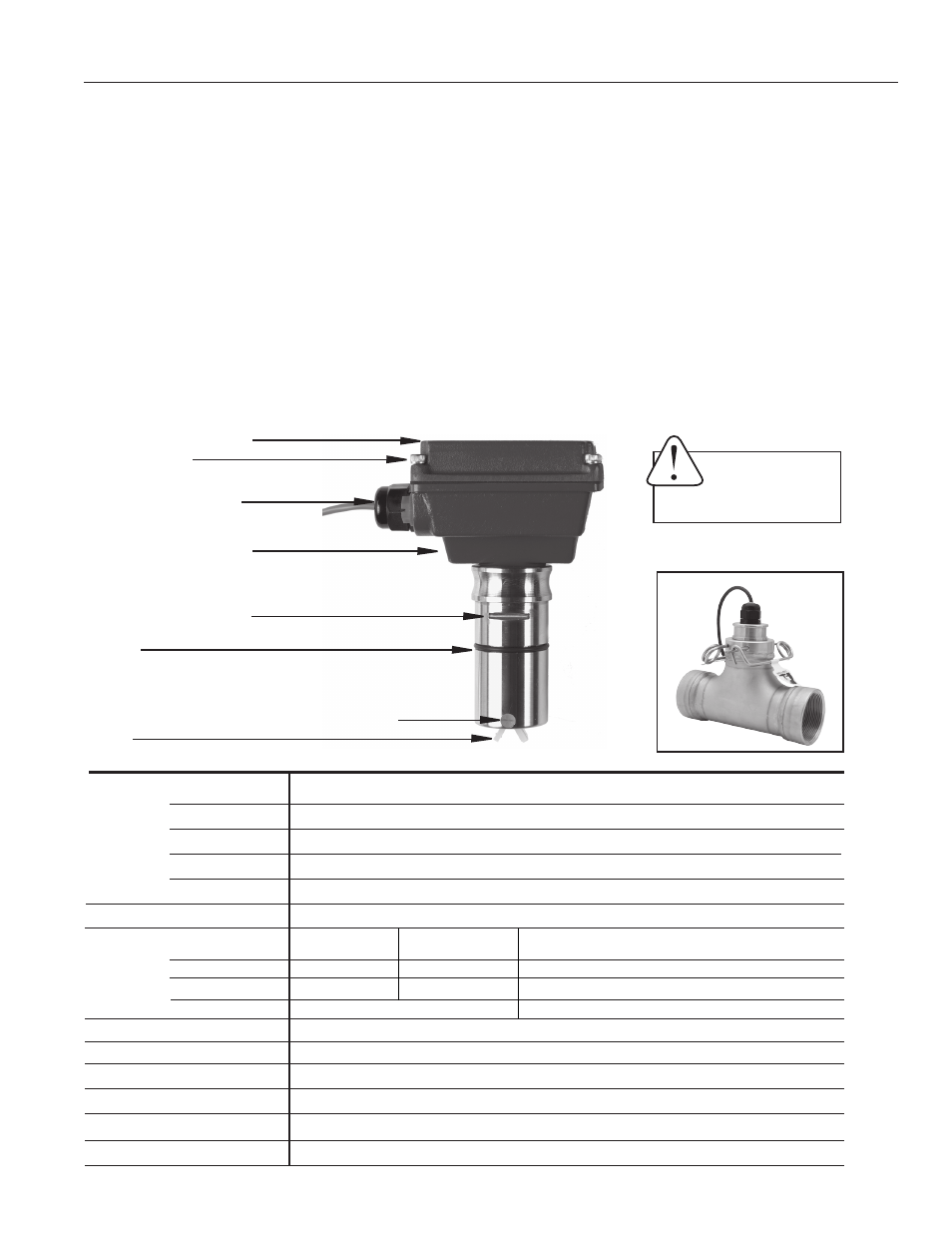

Caution:

Clip(s)

must be installed

before use.

FEATURES

Rotor

O-Ring

Retaining Slot (for U-Clip)

For easy installation at correct depth setting

Lower Housing (optional)

Cable-Seal Strain Relief

Housing Screw

(connect ground to one)

Cover or Optional Module

Jewel Bearings for superior low-flow performance

Page 3

SPECIFICATIONS*

Brass, 316 Stainless Steel, PVC, or Polypro

PVDF

Nickel-bonded tungsten carbide (Ceramic optional)

Ruby jewel

EPDM (Viton optional)

GMR (Giant Magnetoresistive) Sensor

Brass

316 SS

PVC or Polypro

(See Pressure vs. Temp. Chart)

200 PSI (14 bar)

200 PSI (17 bar)

175 PSI (12 bar) @ 75˚ F

Not Available

400 psi (28 bar)

Not Available

200˚ F (93˚ C)

130˚ F (55˚ C)

0.3 - 30 ft./sec.

+/- 1.5% of full scale

Hall effect current sinking pulse

6-24 Vdc, 2 mA

20 mA

#22 AWG, 3 Cond, 18 foot (maximum 2000’ run)

Materials Sensor Body

Rotor

Shaft

Bearings

O-Ring

Rotor Pickup

Maximum

Pressure

High Pressure

Temperature

Flow Range

Accuracy

Signal

Power

Maximum Current

Cable

*Specifications subject to change • Please consult our website for current data (www.seametrics.com).

High Pressure Model