0 °c, Remote operation, Light – Martel Electronics MC1010 User Manual

Page 22

22

Note: The calibrator simulates a 2-wire RTD. To connect 3- or 4-wire transmitter, use stacking

cables, as shown in Figure 17.

4.9-1 Custom RTD

A custom curve-fit PRT may be entered into the calibrator for sourcing and measuring. To

do so follow these steps:

1.

Select the [CONFIG] option from the main menu. Select RTD and set sensor type

to CUSTOM.

2.

Enter the RTD custom setup main menu, and select [SET CUSTOM].

3.

Using the keypad, enter the values that the calibrator prompts for: minimum

temperature, maximum temperature, R0, and the values for each of the

temperature coefficients.

The custom function uses the Calendar-Van Dusen equation for outputting and measuring

custom RTDs. The coefficient C is only used for temperatures below 0°C. Only A and B

coefficients are needed for the range above 0°C, so coefficient C should be set to 0. The

R0 is the resistance of the probe at 0°C. The coefficients for PT385, PT3926, and PT3616

are shown in Table 4 below.

Table 4. RTD Coefficients

RTD

Range(°C)

R0

Coefficient A

Coefficient B

Coefficient C

PT385

-260 - 0

100

3.9083x10-3

-5.775x10-7

-4.183x10-12

PT385

0 - 630

100

3.9083x10-3

-5.775x10-7

---

PT3926

Below 0

100

3.9848x10-3

-5.87x10-7

-4x10-12

PT3926

Above 0

100

3.9848x10-3

-5.87x10-7

---

PT3916

Below 0

100

3.9692x10-3

-5.8495x10-7

-4.2325x10-12

PT3916

Above 0

100

3.9692x10-3

-5.8495x10-7

---

5. Remote Operation

The calibrator can be remotely controlled using a PC terminal, or by a computer program

running the calibrator in an automated system. It uses an RS-232 serial port connection for

remote operation. With this connection the user can write programs on the PC, with Windows

languages like Visual Basic to operate the calibrator, or use a Windows terminal, such as

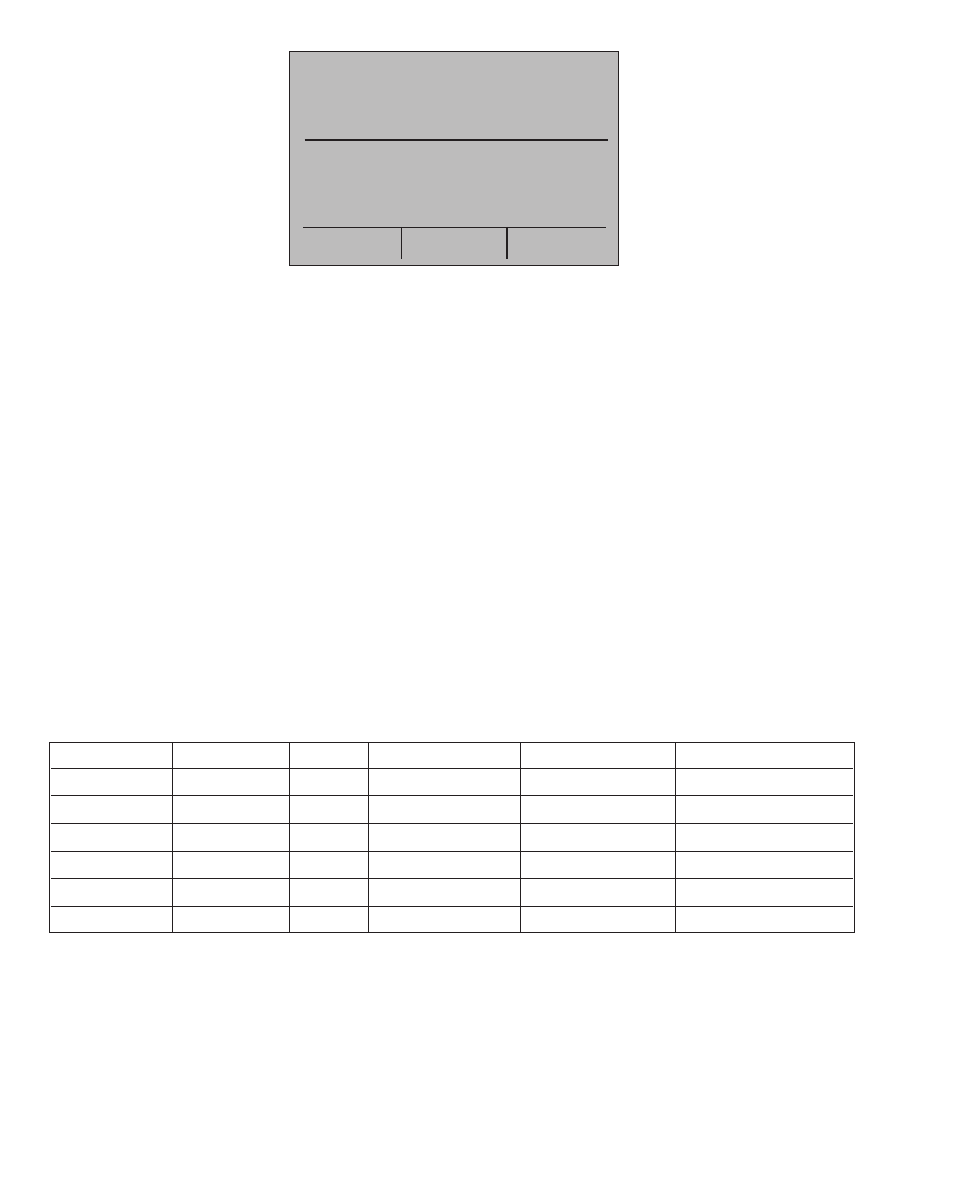

RTD OUT

P200-385

200.0

Ω

MENU

0.0 °C

LIGHT