Basic application information, Specifications – Lake Monitors Flow Transmitters User Manual

Page 4

Basic Application Information

The flow meter can be installed directly in the fluid line without flow

straighteners or special piping. The meter is used to measure the flow

rate of most liquids which do not contain particles greater than 74 micron.

1) External components are sealed inside the Lexan window tube to

permit use in areas where the meter may be sprayed or washed

with soap and water.

2) Mount the meter in the most convenient location to allow easy

access for reading and maintenance.

3) The meter should NOT be mounted near hot pipes or equipment

which can cause deformation of the window tube and scale.

4) The meter should be mounted at least one foot (.3 meter) from

large electric motors, or the internal magnet may weaken or

become demagnetized.

5) Aluminum and brass meters should not be mounted where

assembled piping is not supported.

Page 4 / Flow Meters / Lake Manual

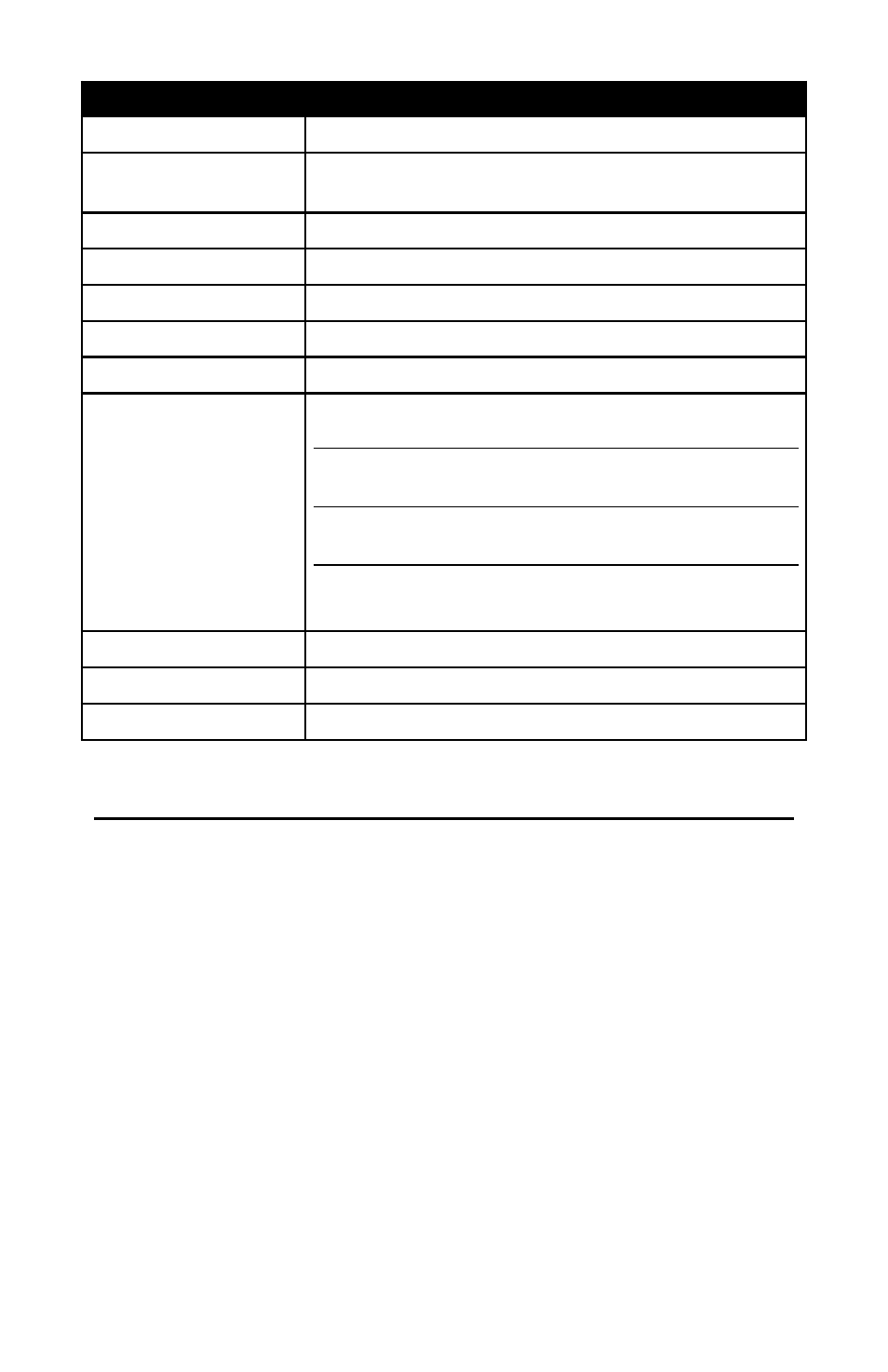

Specifications

Casing Material

Aluminum, Brass or Stainless Steel #304

Maximum Pressure

Aluminum and Brass:

3500 psi (240 Bar)

Stainless Steel #304:

6000 psi (413 Bar)

Maximum Temperature 240ºF (115ºC)

Reading

Direct Reading - 360º Ref. Line (Non-Electrical)

Scale Accuracy

+/- 4% FS, Center 1/3 of scale +/- 2.5% FS

Repeatability

+/- 1% FS

Port Sizes

1/8" - 2" NPTF, #6 - #32 SAE (No Brass) 1/4" - 2" BSP

Installation Dimensions

(Port Sizes/Dimensions)

Series 3

1-7/8" O.D. x 6-9/16" Length

1/4", 3/8", 1/2"

(48mm O.D. x 167mm Length)

Series 4

2-3/8" O.D. x 7-5/32" Length

3/4", 1"

(60mm O.D. x 182mm Length)

Series 5

3-1/2" O.D. x 10-1/8" Length

1-1/4", 1-1/2"

(90mm O.D. x 258mm Length)

Series 5

3-1/2" O.D. x 12-5/8" Length

2"

(90mm O.D. x 322mm Length)

Installation Orientation

Horizontal or Vertical (Scaled Vertically)

Flow Straighteners

Not Required

Test Fluid

Mobile DTE 25 Medium @ 110ºF (43ºC)