Commissioning / operation – KROHNE OPTIWAVE 5200 PROFIBUS User Manual

Page 15

COMMISSIONING / OPERATION

4

15

OPTIWAVE 5200 C

www.krohne.com

10/2013 - 4003066901 - MA OPTIWAVE5200C-PA-R01-en-

Status = Limits

Check the first two quality bits in order to get the quality information of the measurement value:

• Good (Non Cascade):

Good (Non Cascade):

Good (Non Cascade):

Good (Non Cascade): function block output value is ok and can be used without restrictions

• Good (Cascade):

Good (Cascade):

Good (Cascade):

Good (Cascade): will not be supported, because it is not applicable for the device

• Uncertain:

Uncertain:

Uncertain:

Uncertain: function block output value can be used but the accuracy can not be guaranteed

(function block outputs value has been frozen, A/D converter is saturated or out of range, ...)

• Bad:

Bad:

Bad:

Bad: function block output value is bad - do not use it for process control!

The "Quality-Substatus" and "Limit" bits will be used for further diagnostics or limit checking.

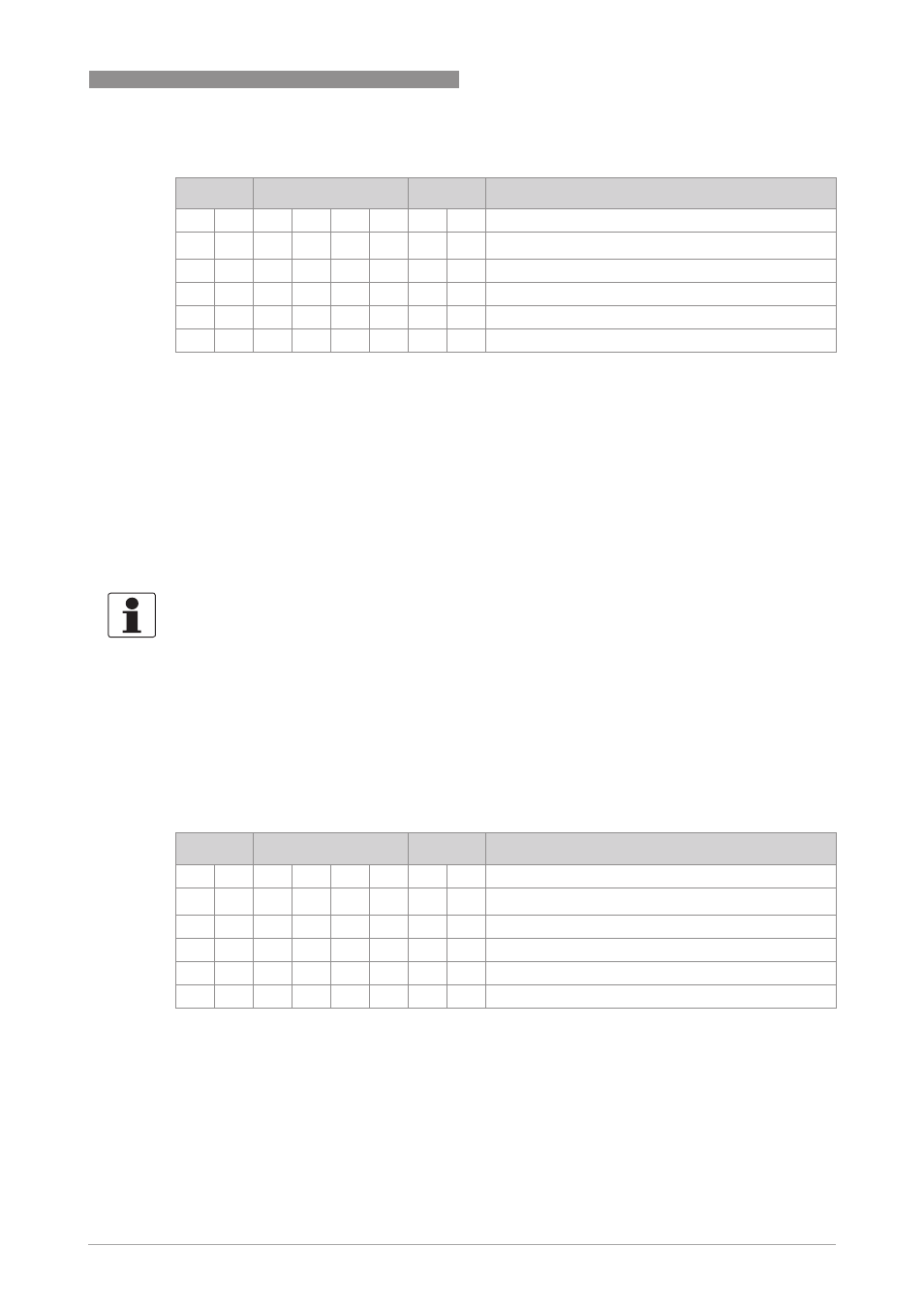

Classic Status

Classic Status

Classic Status

Classic Status

The Classic Status is implemented to provide compatibility to systems which are not configured

for Condensed Status. The coding is shown in the following table:

Quality

Quality substatus

Limits

Gr

Gr

QS

QS

QS

QS

Qu

Qu

2

7

2

6

2

5

2

4

2

3

2

2

2

1

2

0

0

0

= ok

0

1

= low limited

1

0

= high limited

1

1

= constant

INFORMATION!

The status should be monitored because a number will be transmitted even if the status of the

measurement value is bad or uncertain. This is the only way to check the quality of the

transmitted measurement values.

Quality

Quality substatus

Limits

Gr

Gr

QS

QS

QS

QS

Qu

Qu

2

7

2

6

2

5

2

4

2

3

2

2

2

1

2

0

0

0

= bad

0

1

= uncertain

1

0

= good (Non Cascade)

1

1

= good (Cascade) - not supported