Installation, 3 installation steps for npt connections – KROHNE OPTIBAR P 1010 C EN User Manual

Page 13

INSTALLATION

3

13

OPTIBAR P 1010 C

www.krohne.com

06/2014 - 4002622102 - MA OPTIBAR P1010C R02 en

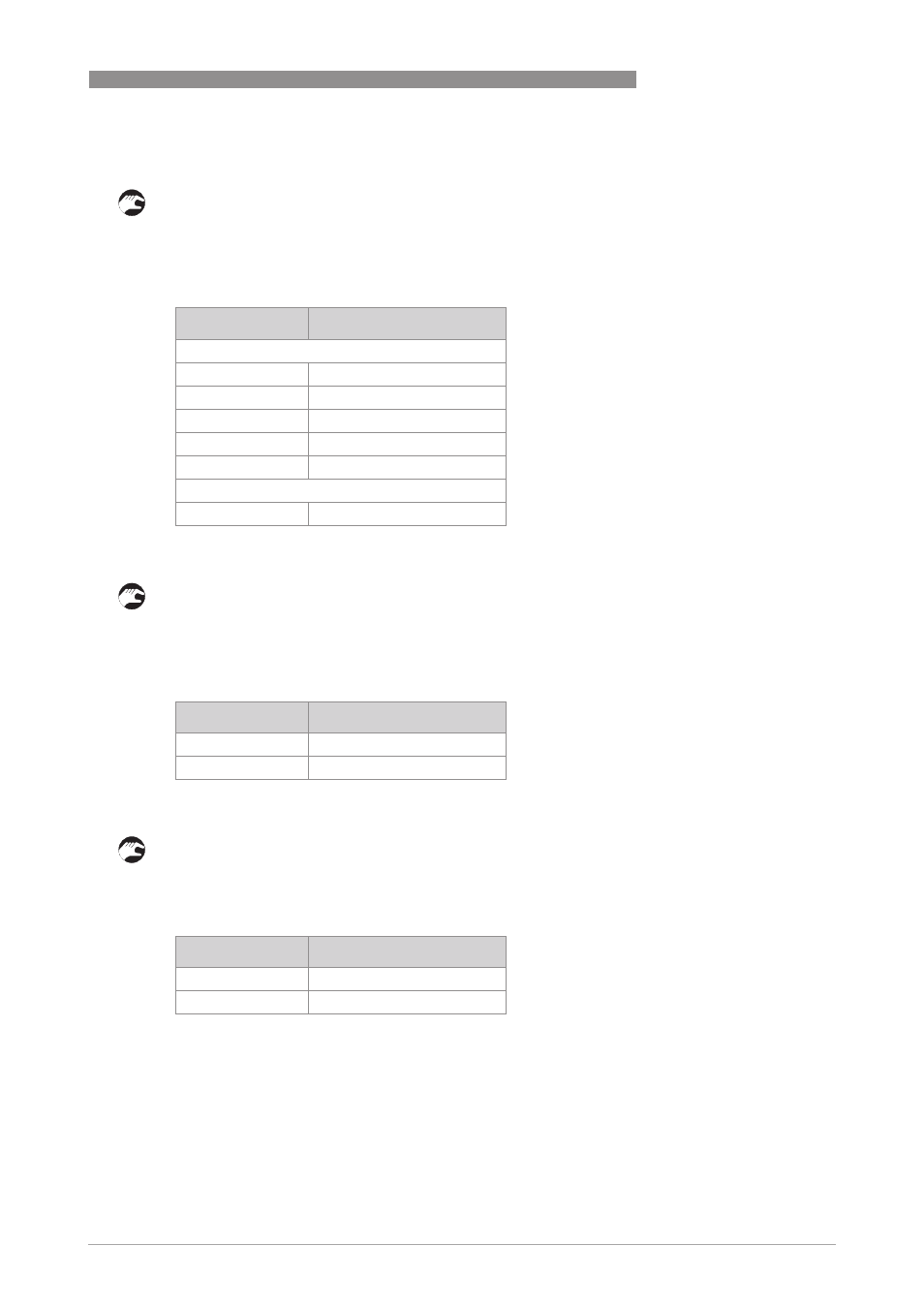

3.3.1 Installation steps for connections acc. to DIN 3852

• Make sure that the O-ring fits properly in the intended groove.

• Ensure that the raised face of the receiving part has a smooth surface.

• Screw the device into the thread by hand.

• Devices with wrench flats must be tightened with a wrench. For information on tightening

torque refer to the following table.

3.3.2 Installation steps for connections acc. to EN 837

• When sealing, use a suitable gasket that corresponds to the product and pressure to be

measured (e.g. a copper gasket).

• Ensure that the raised face of the receiving part has a smooth surface.

• Screw the device into the thread by hand.

• Then tighten the device with the wrench.

3.3.3 Installation steps for NPT connections

• When sealing, use a suitable sealing agent that is compatible with the product (e.g. PTFE

tape).

• Screw the device into the thread by hand.

• Then tighten the device with the wrench.

Wrench size

Tightening torque [Nm]

Wrench size of steel

Wrench size of steel

Wrench size of steel

Wrench size of steel

G1/4

approx. 5

G1/2

approx. 10

G3/4

approx. 15

G1

approx. 20

G1 1/2

approx. 25

Wrench size of plastic

Wrench size of plastic

Wrench size of plastic

Wrench size of plastic

All sizes

max. 3

Wrench size

Tightening torque [Nm]

G1/4

approx. 20

G1/2

approx. 50

Wrench size

Tightening torque [Nm]

1/4 NPT

approx. 30

1/2 NPT

approx. 70