Device description, 2 nameplates 2.3 csa dual seal – KROHNE OPTIMASS 1000 EN User Manual

Page 12

2

DEVICE DESCRIPTION

12

OPTIMASS 1000

www.krohne.com

04/2011 - 4000977901 - MA OPTIMASS 1000 R01 en

2.1.1 Meters with hygienic connections

2.2 Nameplates

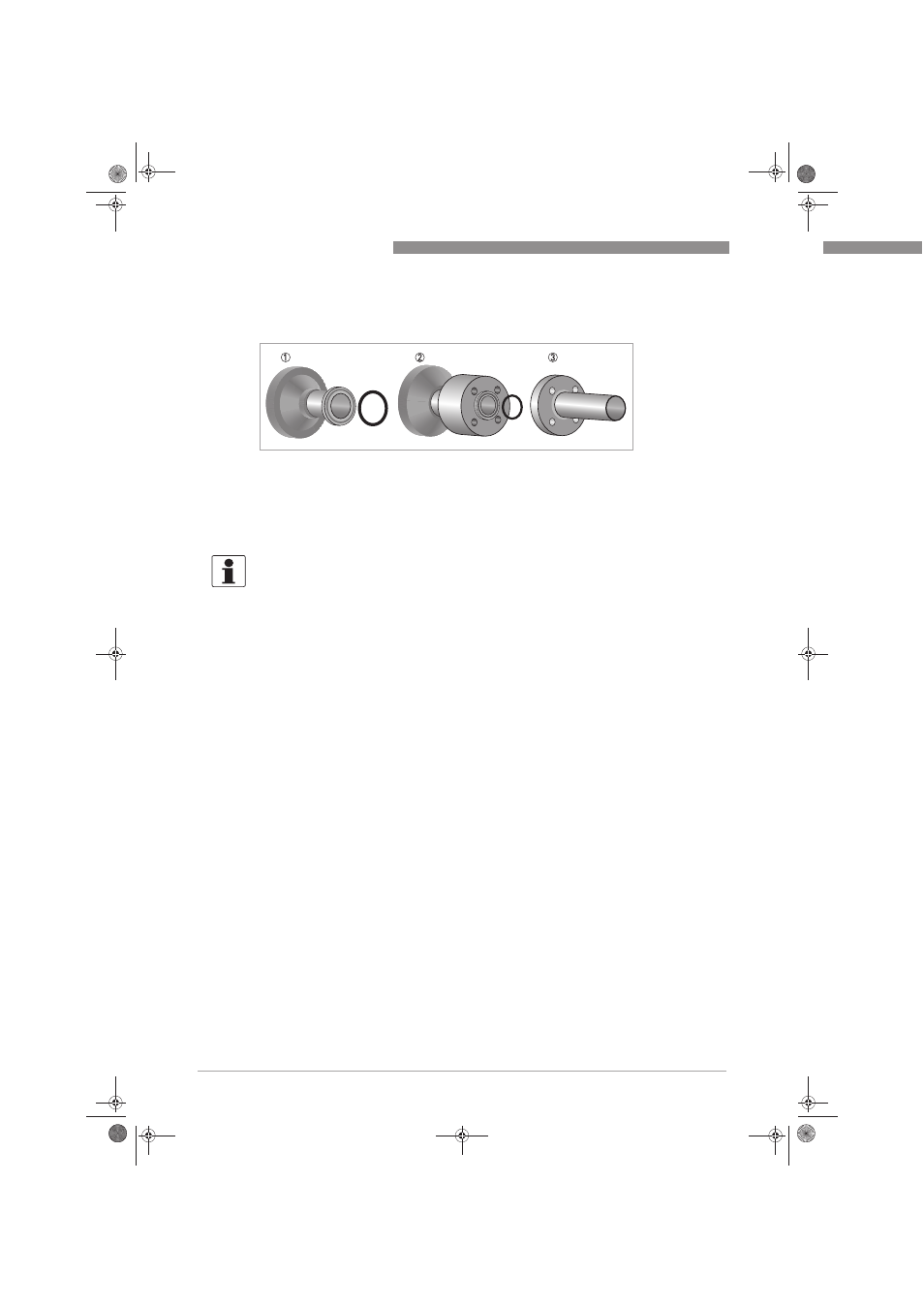

2.3 CSA Dual Seal

To comply with the requirements of ANSI/ISA -12.27.01-2003 “Requirements for process Sealing

Between electrical systems and Flammable or Combustible process Fluids” a secondary seal is

incorporated into all OPTIMASS / GAS products. If the primary seal fails, the secondary seal will

prevent escaping fluid reaching the electronic compartment.

Pressures and / or temperatures are limited by tube, temperature, connection and Ex limits.

Check the meter nameplates and relevant documentation for full details. On all meters

operating on gas measurement, the casing of the meter is fitted with a burst disc. If the primary

seal (tube) fails leakage will occur from the burst disc. Install the meter so that the burst disc is

pointing away from personnel.

Liquids

Liquids

Liquids

Liquids (Example model code: OPTIMASS 1000C S25 - LIQUID)

Pressure and temperature data:

Pressure and temperature data:

Pressure and temperature data:

Pressure and temperature data:

OPTIMASS 1000 / 1300 / 1010 -40°C...+130°C and 100...10000 kPa

Pressures and/or temperatures may be further limited by tube, temperature, connection and Ex

limits. Consult the meter nameplate and relevant documentation for full details.

If the primary seal fails, the casing of the meter will fill with liquid and the meter will stop

working. The meter will notify the operator by going into

will be shown on the converter or PLC display. This is an indication that the primary seal (tube)

has failed and the status of the meter should be checked.

Meter status:

Meter status:

Meter status:

Meter status:

The meter will also go into

completely filled with fluid. For example, if the meter is drained or re/filled.

1 Fully welded - the O-rings between the meter and the process pipework are not supplied as standard but can be or-

dered.

2 DIN 11864-2 Form A - the O-rings between the Form A and Form B parts of the connection are not supplied as standard

but can be ordered.

3 The 11864-2 Form B is not supplied as part of this connection but it can be ordered.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

MA_OPTIMASS_1000_en_110401_4000977901_R01.book Page 12 Friday, April 1, 2011 1:41 PM