KROHNE ALTOSONIC III EN User Manual

Page 6

ALTOSONIC

III

6

2. Mechanical

Installation

2.1 Handling the

flowmeter

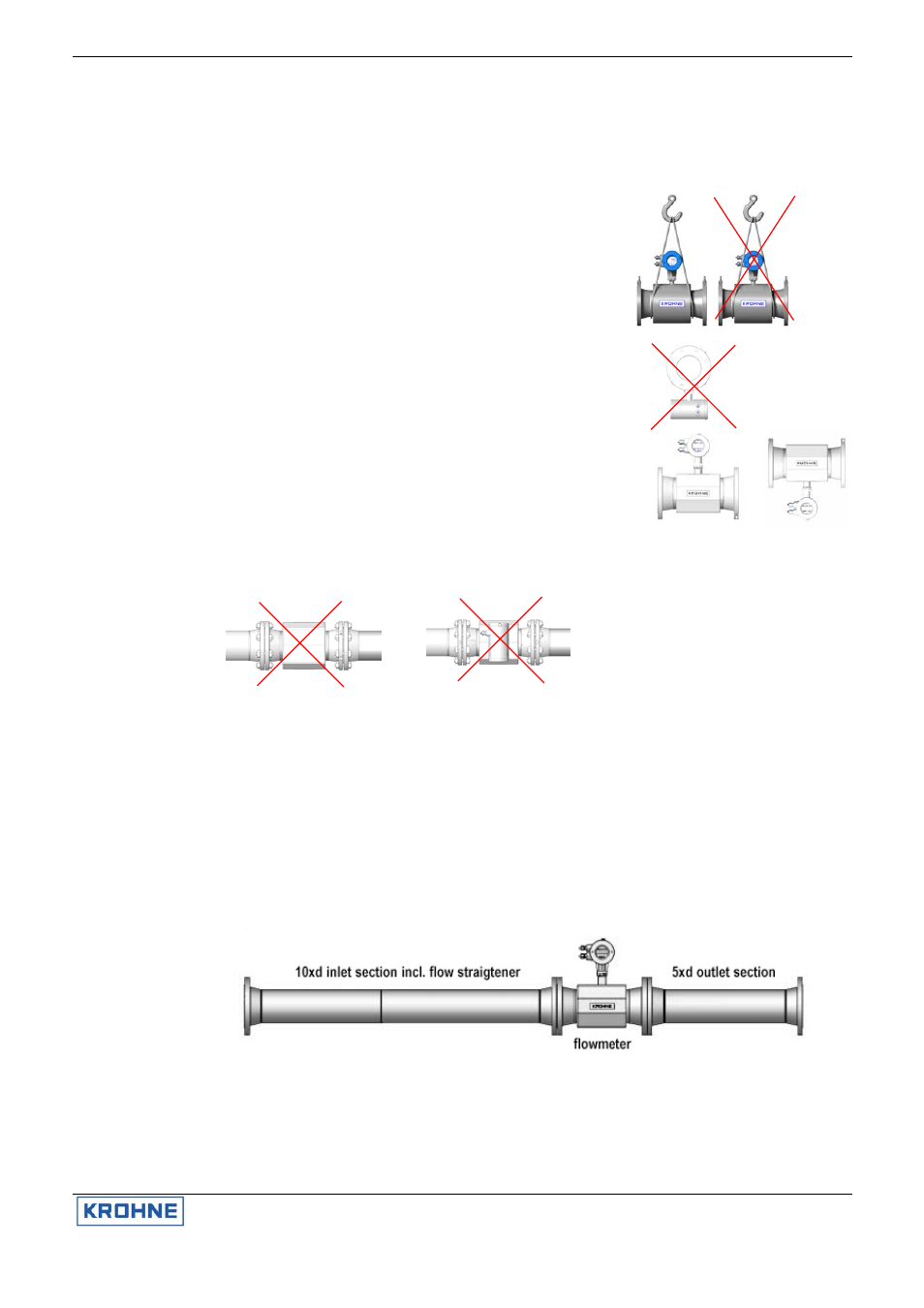

Important: Do not lift the flowmeter by the signal converter housing or the

terminal box. Check the weight of the flowmeter as indicated on the type

plate before handling the unit. When handling the flowmeter avoid hard

blows, jolts or impacts.

Do not place the flowmeter on the signal converter housing.

2.2 Installation location

and position

As the ALTOSONIC III is used in hydrocarbon pipelines, be aware of

potentially explosive atmospheres. Local standards and regulations must be

respected.

The flow sensor must be completely filled at all times for proper flow

measurement. Non-wetted sensors show loss of signal. There is no damage

when this occurs.

The sensor must be installed in a horizontal or vertical position. A correct

position of the unit guarantees a completely filled flow sensor and accurate

flow measurement.

Inlet and outlet sections

For functioning within stated accuracy the flow sensor has to be installed with specified inlet flow conditioner and outlet

sections. The flow conditioner is delivered as a part of the flowmeter as the flow sensor and flow conditioner are calibrated

together for optimal performance.

Inlet configurations (upstream): Straight inlet section, length 10 D with ISO tube bundle flow conditioner.

Outlet configuration (downstream): Straight outlet section, length 5 D.

D = nominal diameter of the flow sensor.

It is advised to keep length of 5 D straight pipe section upstream between flow conditioner and upstream disturbances.

Bush guides

Every ALTOSONIC III is calibrated in combination with a dedicated inlet flow

conditioner. To minimize the installation effects on the performance of the

ALTOSONIC III a provision is made to assure that the flow conditioner

versus the ALTOSONIC III have the same position at operation as during the

initial calibration.