Installation in hazardous areas, zone 1 and zone 2 – KROHNE ALTOSONIC III EN User Manual

Page 27

Installation and operating instructions

27 ALTOSONIC

III

5. Installation in

hazardous

areas, zone 1

and zone 2

5.1 Approvals

The ALTOSONIC III ultrasonic flowmeters in compact and separate design are in accordance with the European

Directive 94/9 EC (ATEX 100a) and approved for hazardous classified locations of Zone 1 and 2 by the PTB conform to

the European Standards of the EN 500xx series, approval number: PTB 03 ATEX 2021 X.

5.2 Compact flowmeter

The standard ALTOSONIC III C-EEx compact flowmeter is designed for ambient temperatures (i.e. Ta) in the range of

-40°C / 104°F up to +70°C/158°F. The maximum allowed process liquid (medium) temperature is restricted by the

combustible atmosphere that (possibly) surrounds the apparatus, determined by the temperature class of the

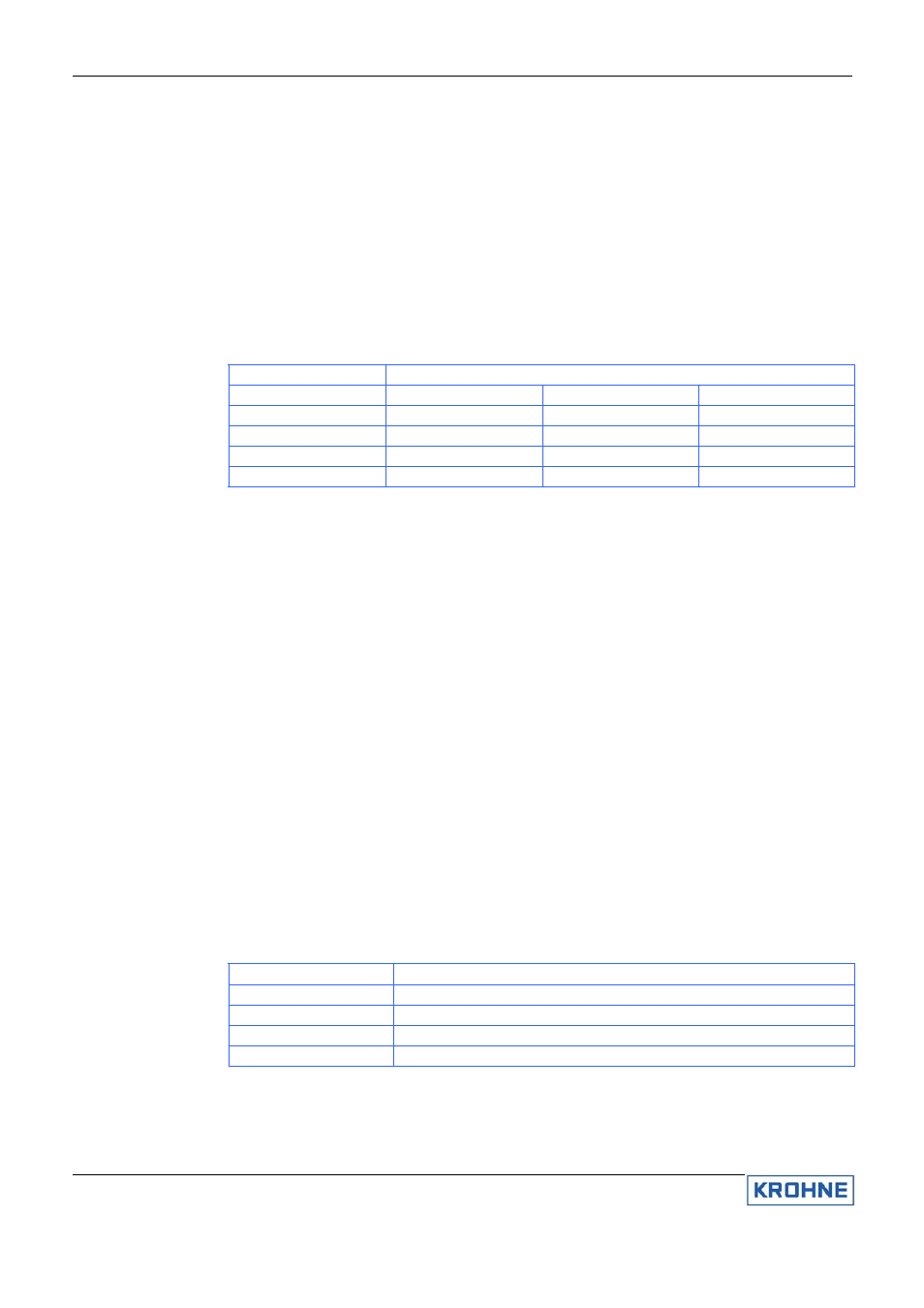

atmosphere, see table below.

Temperature class

Maximum process liquid temperature at

Ta

≤ 40°C / 104°F

Ta ≤ 50°C / 122°F

Ta ≤ 60°C / 140°F

T6

80°C / 176°F

80°C / 176°F

80°C / 176°F

T5

95°C / 203°F

95°C / 203°F

95°C / 203°F

T4

130°C / 266°F

130°C / 266°F

125°C / 257°F

T3

180°C / 356°F

165°C / 329°F

125°C / 257°F

The ALTOSONIC III K/…-EEx compact flowmeter consists of the UFC III…-EEx flow converter that is screwed on top of

the UFS III-EEx flow sensor by four hexagonal socket head cap screws of size M6. The standard compact flowmeter is

marked with one of the codes below:

Standard: II 2G EEx de [ib] IIC T6…T3 for the terminal compartment of the flow converter housing in type of protection

increased safety "e" according to EN 50019.

Optional: II 2G EEx d [ib] IIC T6…T3 for the terminal compartment of the flow converter housing designed as

flameproof enclosure "d" according to EN 50018.

5.3 Flow sensor

The UFS III…-EEx flow sensor is the measuring unit of the ALTOSONIC III (3-beam) ultrasonic flowmeters. It contains

the ultrasonic sensor (three pairs of opposite transducers) in type of protection intrinsic safety category "ib" according to

EN 50020. All sensor circuits are wired by separate coaxial cables and connected through SMB connectors, which are

marked by the respective numbers 1.1, 1.2, 2.1, 2.2, 3.1 and 3.2. The flow sensors are available in size DN25 (1”) up to

DN1000 (40”) in diameter.

The UFS III…-EEx flow sensor is used in combination with the flow converter unit type UFC III…-EEx, which is either

directly mounted on top of the flow sensor (compact meter) or installed on a distance and connected via a cable

(separate version). In the last case the flow sensor as well as the flow converter unit are both provided with a junction

box, in which the SMB connectors are mounted.

The UFS III F/…-EEx flow sensor in separate design is the measuring unit of the separate flowmeter system. The

sensor is suitable for process liquid temperatures from -25°C/-13°F up to +180°C/356°F and designed for an ambient

temperature in the range of -40°C/-40°F up to +70°C/158°F.

The UFS III F/…-EEx flow sensors in separate design are classified according to the temperature classification table

below.

Temperature class

Maximum process liquid temperature at Ta = 60°C / 140°F

T6

80°C / 176°F

T5

95°C / 203°F

T4

130°C / 266°F

T3

180°C / 356°F

The UFS III F/…-EEx flow sensors are marked with the explosion safety codes: UFS III F-EEx: II 2G EEx ib IIC T6…T3.

The intrinsically safe "ib" ultrasonic sensor circuits inside the UFS III…-EEx flow sensor have the following maximum

values (i.e. entity parameters):

Maximum input voltage : V

max

= 13.1 V