Installation – KROHNE OPTIFLUX 1000 EN User Manual

Page 19

INSTALLATION

3

19

OPTIFLUX 1000

www.krohne.com

04/2014 - 4000846303 - HB OPTIFLUX 1000 R03 en

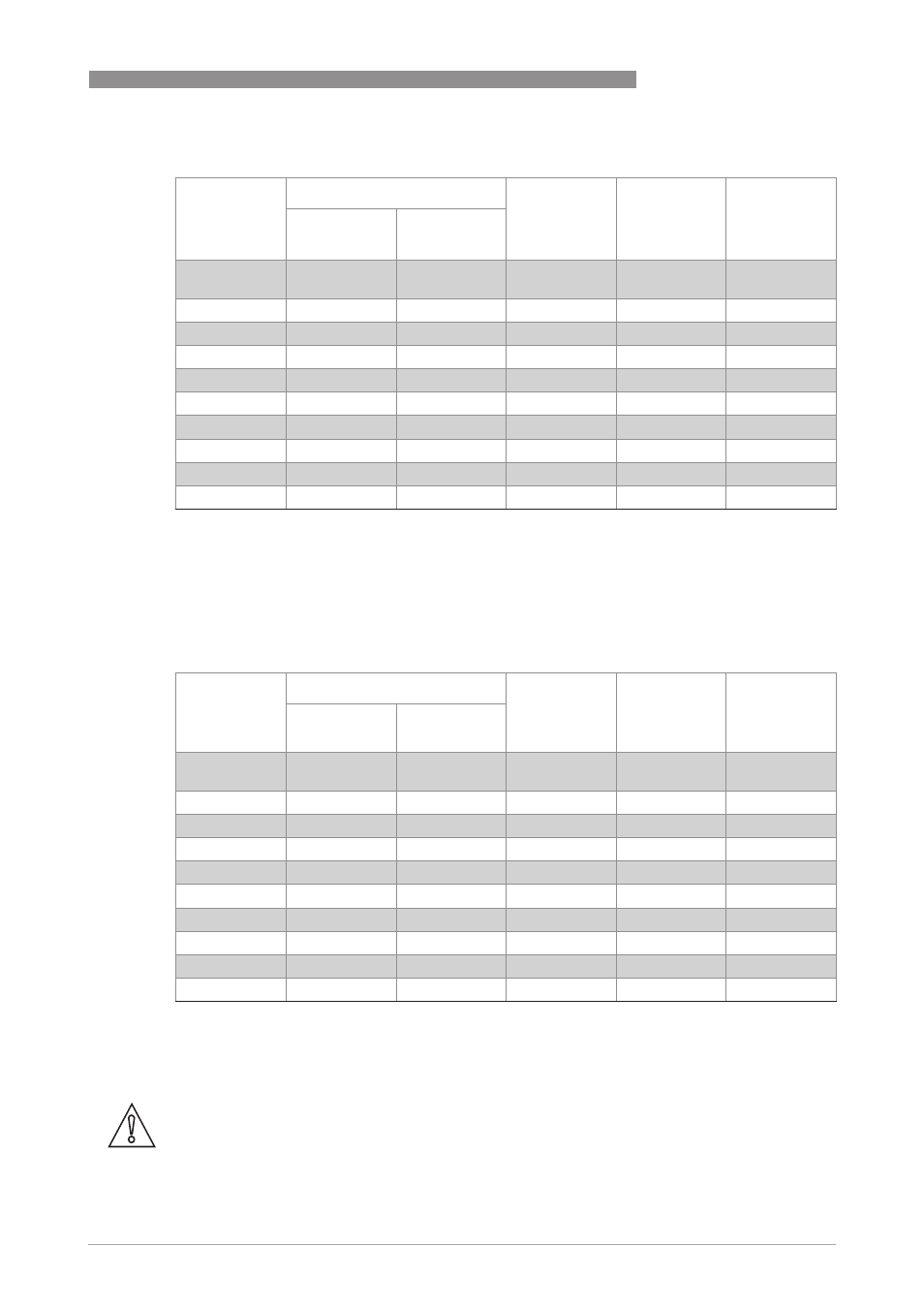

EN 1092-1

ASME B 16.5

Nominal size

DN [mm]

Counter flanges

Maximum

operating

pressure

[bar]

Bolts

Max. torque

[Nm]

2

Flange size

DN [mm]

Flange class

[lb]

10

15

1

PN 16/40

≤16

4 x M12

16

15

15

PN 16/40

≤16

4 x M12

16

25

25

PN 16/40

≤16

4 x M12

16

40

40

PN 16/40

≤16

4 x M16

25

50

50

PN 16/40

≤16

4 x M16

45

80

80

PN 16/40

≤16

4 x M16

25

100

100

PN 16

≤16

8 x M16

33

100

100

PN 40

≤16

8 x M20

33

150

150

PN 16

≤16

8 x M20

82

150

150

PN 40

≤16

8 x M24

82

1 For DN10 and 15 sizes use DN15 counter (pipe) flanges.

2 The specified torque values are dependent on variables (temperature, bolt material, gasket material, lu-

bricants, etc.) which are not within the control of the manufacturer. Therefore the values should be re-

garded as indicative only.

Nominal size

DN [inch]

Counter flanges

Max. operating

pressure

[psig]

Bolts

Max. torque

[lbs.ft]

2

Flange size

DN [inch]

Flange

class[lb]

3/8"

1/2"

1

150/300 lb

230

4 x 1/2"

11.6

1/2"

1/2"

150/300 lb

230

4 x 1/2"

11.6

1"

1"

150/300 lb

230

4 x 1/2"

10.8

1 1/2"

1 1/2"

150/300 lb

230

4 x 1/2"

18.1

2"

2"

150/300 lb

230

4 x 5/8"

32.5

3"

3"

150 lb

230

4 x 5/8"

40.5

3"

3"

300 lb

230

8 x 5/8"

20.5

4"

4"

150/300 lb

230

8 x 5/8"

26

6"

6"

150 lb

230

8 x 3/4"

72.3

6"

6"

300 lb

230

12 x 3/4"

47.7

1 For DN3/8" and 1/2" use DN1/2" counter (pipe) flanges.

2 The specified torque values are dependent on variables (temperature, bolt material, gasket material, lu-

bricants, etc.) which are not within the control of the manufacturer. Therefore the values should be re-

garded as indicative only.

CAUTION!

•

Pressures are applicable at 20

°

C / 68

°

F.

•

For higher temperatures, the pressure ratings are as per ASME B16.5.