Technical data, 2 assumptions – KROHNE OPTIFLEX 2200C SIL User Manual

Page 27

TECHNICAL DATA

9

27

OPTIFLEX 2200 C

www.krohne.com

01/2013 - 4000738603 - AD SIL OPTIFLEX 2200 R03 en

9.1 General notes

The device agrees with these conditions in the IEC 61508 standard:

9.2 Assumptions

FMEDA is applicable for the conditions that follow:

• Use of the device agrees with its design and performance characteristics. This includes

ambient and process conditions.

• Installation of the device must agree with the instructions and the requirements of the

application.

• We can ignore wear of mechanical parts. Failure rates are constant.

• Failures that follow one after the other are put in the same group as the failure that is the

source of the problem.

• The HART

®

protocol is only used for set-up, calibration and diagnostic purposes. It is not

used during safety operation mode.

• All components that are not part of the safety function and cannot influence the safety

function (feedback immune) are not included.

• Only the analog output (4…20 mA) is used for safety applications.

• The Mean Time to Recovery after safe failure is 72 hours (MTTR = 72 h).

• If necessary, the device can operate as a safety-related system in a low-demand mode of

operation.

• External power failure rates are not included.

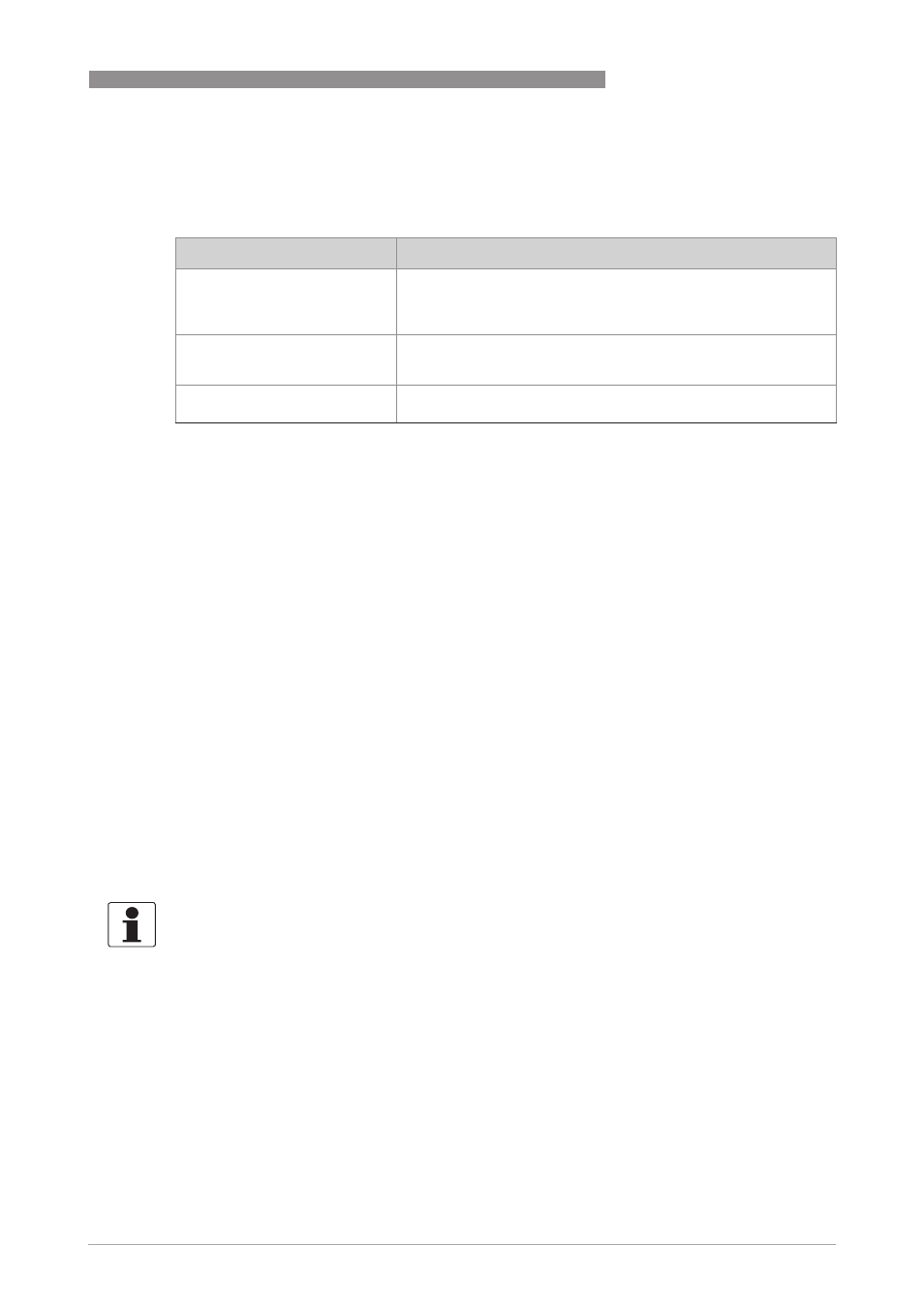

Condition

Description

The device operates in high

demand or continuous mode of

operation

1

The device continuously measures the distance to the surface of the

product in the tank. If electrical power is not available or is not

sufficient, the device will not measure. The safety function is

continuously available to keep the device in a safe state.

The device is a type B system

The device uses programmable electronics embedded in complex

components (a microcontroller). It is not possible to find all the

failure modes for this type of component.

The device has a hardware fault

tolerance of zero (HFT = 0)

The device does not have hardware redundancy.

1 This agrees with IEC 61508 Part 4, section 3.5.16

INFORMATION!

The FMEDA of the device was calculated with the exida

exida

exida

exida tool FMEDA v7.1.17, with the

configuration that follows:

•

Database SN 29500

•

Ambient temperature is 40

°

C

•

T[Proof] is from 1 to 10 years (87600 hours)

•

T[Repair] is 72 hours

•

T[Test] is 24 hours (all internal test functions are done a minimum of one time during this

period)