Electrical connection, 1 topology of a profibus pa network – KROHNE OPTIWAVE 5200 PROFIBUS User Manual

Page 6

3

ELECTRICAL CONNECTION

6

OPTIFLEX 2200 C

www.krohne.com

10/2013 - 4003066801 - MA OPTIFLEX2200C-PA-R01-en-

3.1 Topology of a PROFIBUS PA network

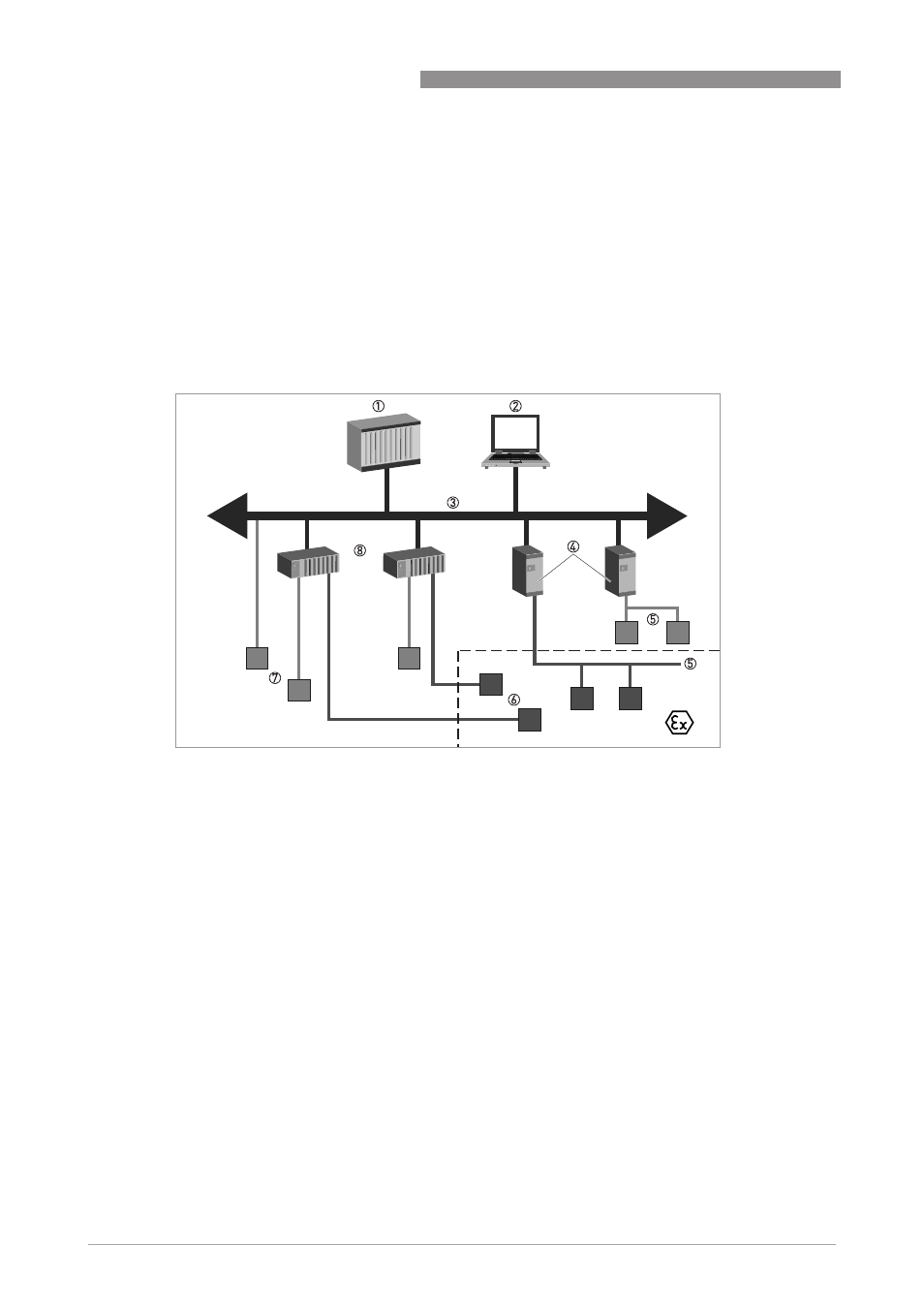

The following diagram shows a typical network configuration with PROFIBUS PA devices in

hazardous and non-hazardous areas, as well as the connection of conventional non-PROFIBUS

devices (e.g. with 4 … 20 mA signals) to a PROFIBUS network.

The PROFIBUS PA segment is connected to a segment coupler which, among other things,

provides the conversion to the PROFIBUS DP bus line. In addition it provides the power supply for

bus–powered PROFIBUS PA devices. Refer to the instruction manual of the segment coupler

concerning the DP bus parameters, e.g. the supported baud rates.

Refer also to the PROFIBUS PA User and Installation Guideline (Version 2.2, February 2003 PNO

Order No. 2.092).

Figure 3-1: PROFIBUS PA network

1 Control system (PLC); class 1 master

2 Engineering or operation control tool; class 2 master

3 PROFIBUS DP network with max. 12 Mbit/s

4 PROFIBUS PA segment coupler DP / PA

5 PROFIBUS PA network with 31.25 kbit/s

6 HART

®

device

7 More devices with 4…20 mA

8 Analogue I/O module