Commissioning / operation – KROHNE OPTIWAVE 5200 PROFIBUS User Manual

Page 13

COMMISSIONING / OPERATION

4

13

OPTIFLEX 2200 C

www.krohne.com

10/2013 - 4003066801 - MA OPTIFLEX2200C-PA-R01-en-

Status value

Status value

Status value

Status value

The PROFIBUS interface of the level transmitter supports the PROFIBUS-PA Profile Version

3.02. In this Profile the Condensed Status and Diagnosis has replaced by default the Classic

Status and Diagnosis of the PROFIBUS-PA Profile Version 3.0. The Condensed Status and

Diagnosis has been created to make diagnostic events more obvious and to allow predictive and

preventive maintenance. Nevertheless Classic Status and Diagnosis is still available for the level

transmitter. It is implemented for backwards compatibility to "older" devices or PLC systems

which do not support Condensed Status and Diagnosis.

The device may be switched between "Condensed Status and Diagnosis" and "Classic Status and

Diagnosis"

• automatically during start-up of the cyclic data transfer by setting the parameter PRM_COND

within the Set_Prm service data.

• using an engineering tool (e.g. DD/DTM) to write the parameter COND_STATUS_DIAG (slot 0,

index 43).

Coding for both parameters is:

• 0: Classic Status

• 1: Condensed Status (factory setting)

The coding of the status value depends on the active status and diagnosis mode. It is described in

the following tables.

Condensed Status

Condensed Status

Condensed Status

Condensed Status

The Condensed Status codes have been defined to allow easier decoding of the information

provided by the PROFIBUS devices. The coding is shown in the following table:

INFORMATION!

The parameter COND_STATUS_DIAG cannot be modified directly if cyclic data transfer is active.

Nevertheless it is reset to the factory setting if a reset to default data is requested by an

engineering tool.

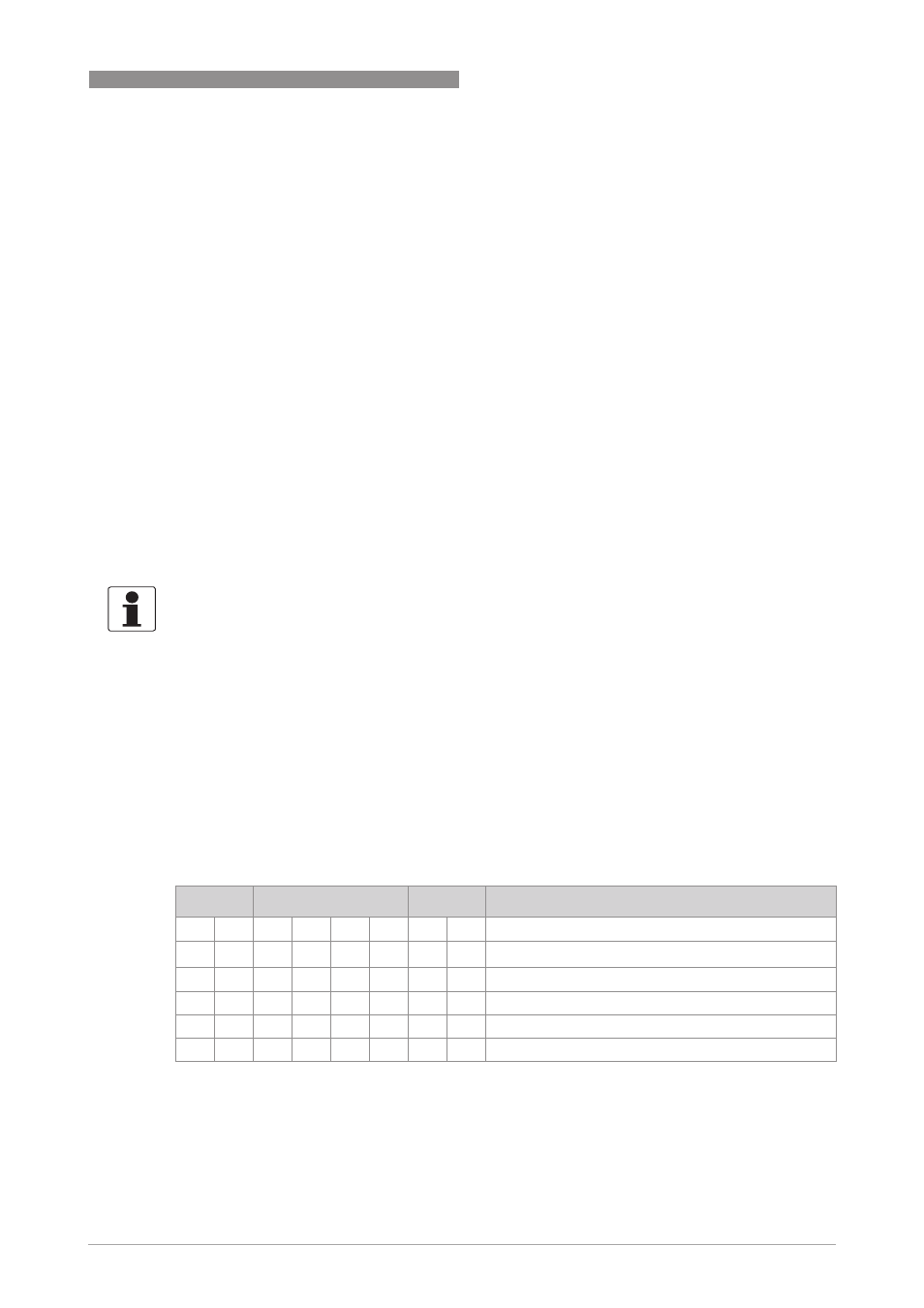

Quality

Quality substatus

Limits

Gr

Gr

QS

QS

QS

QS

Qu

Qu

2

7

2

6

2

5

2

4

2

3

2

2

2

1

2

0

0

0

= bad

0

1

= uncertain

1

0

= good (Non Cascade)

1

1

= good (Cascade) - not supported