Commissioning / operation, 6 diagnosis – KROHNE OPTIWAVE 5200 PROFIBUS User Manual

Page 17

COMMISSIONING / OPERATION

4

17

OPTIFLEX 2200 C

www.krohne.com

10/2013 - 4003066801 - MA OPTIFLEX2200C-PA-R01-en-

Status = Limits

Check the first two quality bits in order to get the quality information of the measurement value:

• Good (Non Cascade):

Good (Non Cascade):

Good (Non Cascade):

Good (Non Cascade): function block output value is ok and can be used without restrictions

• Good (Cascade):

Good (Cascade):

Good (Cascade):

Good (Cascade): will not be supported, because it is not applicable for the device

• Uncertain:

Uncertain:

Uncertain:

Uncertain: function block output value can be used but the accuracy can not be guaranteed

(function block outputs value has been frozen, A/D converter is saturated or out of range, ...)

• Bad:

Bad:

Bad:

Bad: function block output value is bad - do not use it for process control!

The "Quality-Substatus" and "Limit" bits will be used for further diagnostics or limit checking.

4.6 Diagnosis

The device does internal self-tests. The results are given as detailed diagnosis data that agrees

with PROFIBUS PA Profile 3.02. You can set device parameters to see the diagnosis data and you

can also use an engineering tool (DD/DTM, ...) to read it. Cyclic services transfer diagnosis data

to the control system (PLC, ...).

Diagnosis is bitwise coded. Thus it is possible to report more than one indication simultaneously.

The GSD file contains a text for each diagnosis bit to show a text message in the control system.

The references are specified in the UNIT_DIAG_BIT(i) entries. They show which bit is set to

indicate a special diagnosis event.

The quantity and content of diagnosis data depends on the device settings. The active Ident.

Number and the selected status and diagnosis mode will have an effect diagnosis propagation.

The tables that follow show the diagnosis events which are reported for different settings. The

bit number is equal to the count in the GSD file. It gives the position in the device-related

diagnostic field of the Slave_Diag service.

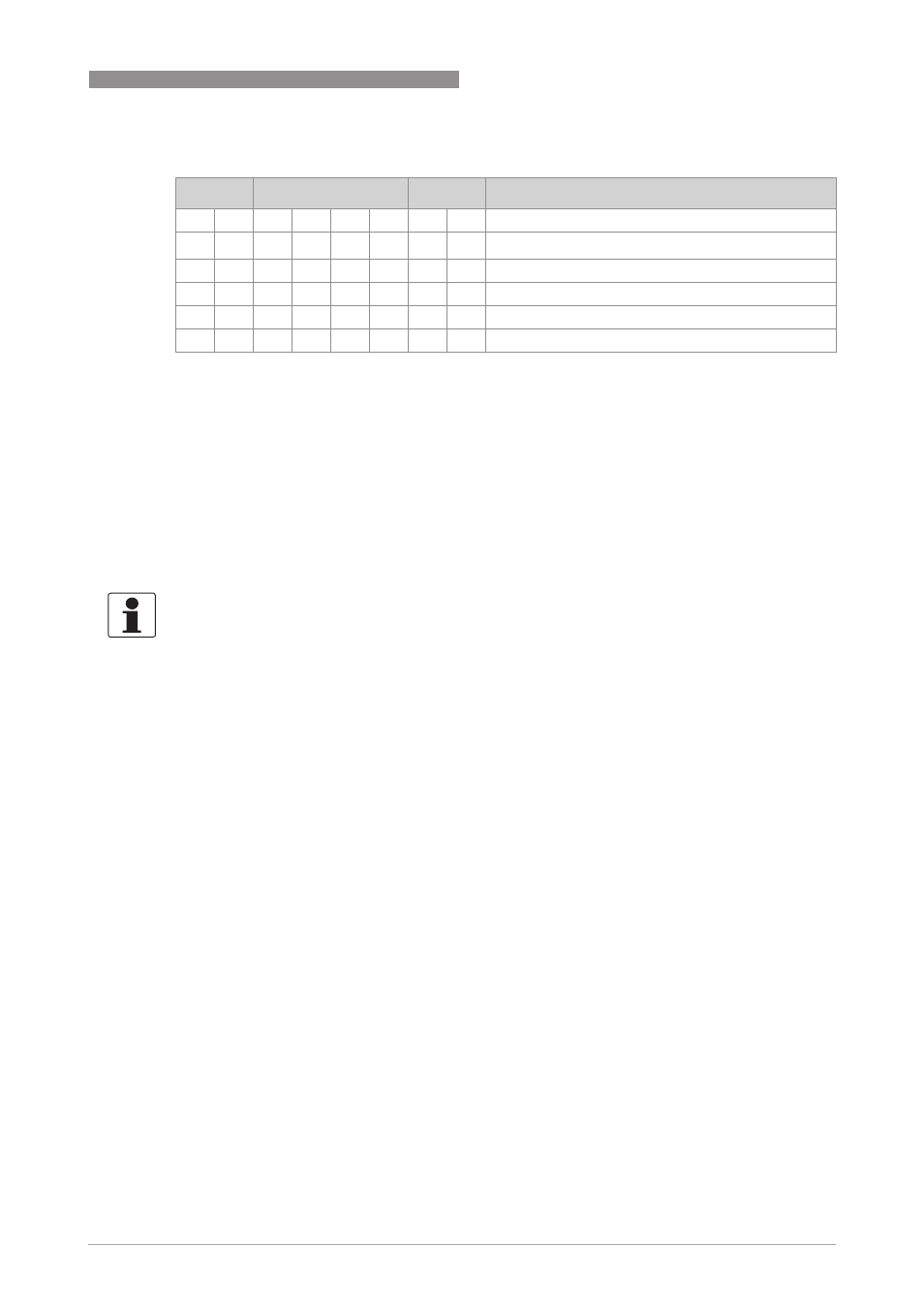

Diagnosis to control system in case of

• Manufacturer specific Ident. Number (4550hex)

• Profile specific Ident. Number (9700hex)

Quality

Quality substatus

Limits

Gr

Gr

QS

QS

QS

QS

Qu

Qu

2

7

2

6

2

5

2

4

2

3

2

2

2

1

2

0

0

0

= ok

0

1

= low limited

1

0

= high limited

1

1

= constant

INFORMATION!

The status should be monitored because a number will be transmitted even if the status of the

measurement value is bad or uncertain. This is the only way to check the quality of the

transmitted measurement values.