Modbus protocol – KROHNE MFC 300 Modbus User Manual

Page 20

6

MODBUS PROTOCOL

20

MFC 300

www.krohne.com

11/2009 - 4000744801 - AD Modbus MFC 300 R01 en

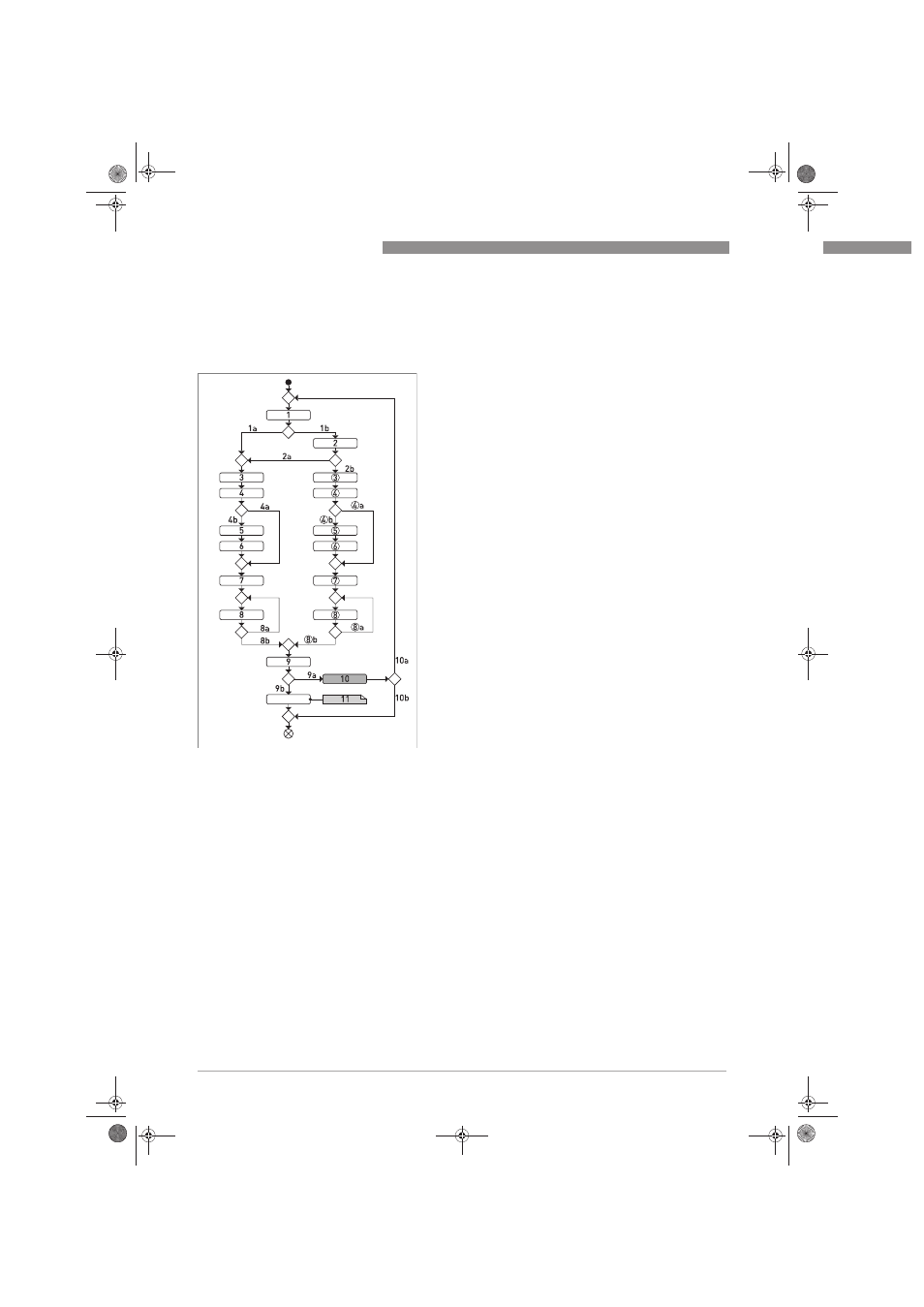

6.10.4 Two Point Density Calibration

After first calibration pint, fluid inside the meausing sensor must be changed and the calibration

procedure started again.

1

Read densisty calibration status:

Read densisty calibration status:

Read densisty calibration status:

Read densisty calibration status:

Read Holding Register 44000 type byte

(Modbus Fct. 0x03)

1a / 1b

[status = 0] / [status = 1]

2

User selects calibration point:

User selects calibration point:

User selects calibration point:

User selects calibration point:

2a

Repeat 1st calibration point

2b

Start 2nd calibration point

3 & 3

User selects actual density type:

User selects actual density type:

User selects actual density type:

User selects actual density type:

0: Empty; 1: pure water; 2: town water; 3: other

4

Write DCF1 value (density type):

Write DCF1 value (density type):

Write DCF1 value (density type):

Write DCF1 value (density type):

Write Holding Register 44001 type byte

(Modbus Fct. 0x10)

4a / 4b

[DCF1 <> 3: Not Other] / [DCF1 = 3: Other]

4

Write DCF5 value (density type):

Write DCF5 value (density type):

Write DCF5 value (density type):

Write DCF5 value (density type):

Write Holding Register 44002 type byte

(Modbus Fct. 0x10)

4a

[DCF5 <> 3: Not Other]

4b

[DCF5 = 3: Other]

5 & 5

User enters actual density value:

User enters actual density value:

User enters actual density value:

User enters actual density value:

6

Write DCF2 value (density value in kg/m

Write DCF2 value (density value in kg/m

Write DCF2 value (density value in kg/m

Write DCF2 value (density value in kg/m

3

33

3

):

Write Holding Register 43004 type float

(Modbus Fct. 0x10)

6

Write DCF6 value (density value in kg/m

Write DCF6 value (density value in kg/m

Write DCF6 value (density value in kg/m

Write DCF6 value (density value in kg/m

3

33

3

):

Write Holding Register 43010 type float

(Modbus Fct. 0x10)

7

Start density calibration 1st point:

Start density calibration 1st point:

Start density calibration 1st point:

Start density calibration 1st point:

Set single coil 2002 to 1 (Modbus Fct. 0x05)

7

Start density calibration 2nd point:

Start density calibration 2nd point:

Start density calibration 2nd point:

Start density calibration 2nd point:

Set single coil 2003 to 1 (Modbus Fct. 0x05)

8

Check status of calibration:

Check status of calibration:

Check status of calibration:

Check status of calibration:

Read single coil 2002 (Modbus Fct. 0x01)

8a

[2002 = 1: calibration running]

8b

[2002 = 0: calibration complete]

8

Check status of calibration:

Check status of calibration:

Check status of calibration:

Check status of calibration:

Read single coil 2003 (Modbus Fct. 0x01)

8a

[2003 = 1: calibration running]

8b

[2003 = 0: calibration complete]

9

Read Calibration Result

Read Calibration Result

Read Calibration Result

Read Calibration Result

Read Input Register 20000 type byte

(Modbus Fct. 0x04)

9a / 9b

[20000 = 1: fail] / [20000 = 0: pass]

10

User tries to improve the calibration situation

User tries to improve the calibration situation

User tries to improve the calibration situation

User tries to improve the calibration situation

10a

Improvement done

10b

Improvement not possible -Break-

11

This results in a warm start of the device.

Will take maximum 5s.

.book Page 20 Tuesday, November 24, 2009 1:48 PM