KROHNE VARIFLUX 6000 EN User Manual

Page 9

Installation instructions VARIFLUX 6000

9

VARIFLUX 6000 separate flow sensor with terminal box

• A functional ground FE must always be connected.

• Signal converters with a field power supply of > 125 mA / > 60 V:

Because of the higher field current from the signal converter, a PE protective conductor

must be connected to the VARIFLUX 6000 flow sensor, see grounding diagrams.

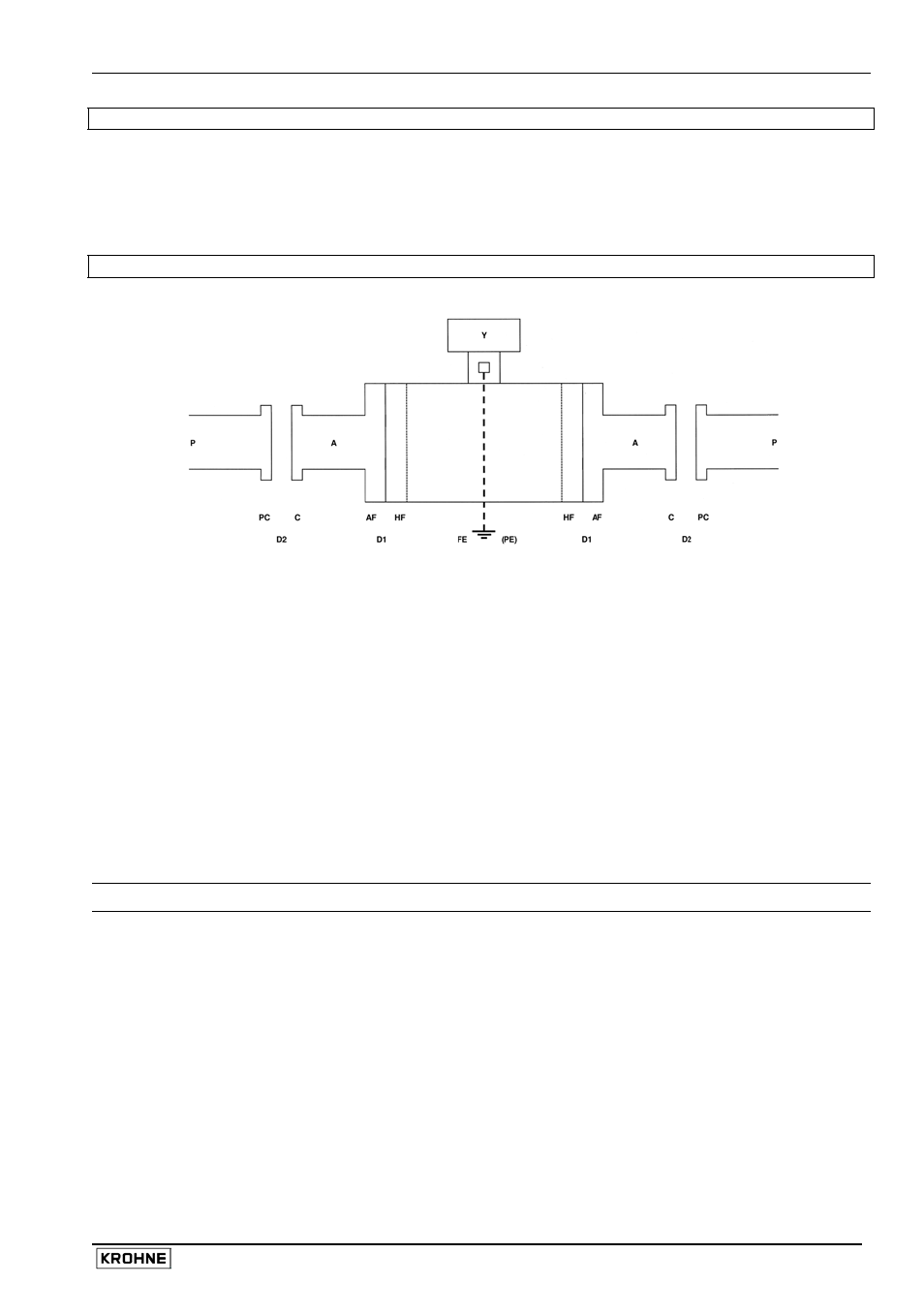

Grounding diagram

Flowmeter with adapters

A

Adapter complete, ready assembled

AF

Adapter flange

C

Adapter connection

D1

L-shaped gasket

D2

Gaskets not included in supply, to be provided by customer

FE

Functional ground, wire

≥ 4 mm

2

Cu, (10 AWG).

HF

Housing flange for adapter

P

Pipeline

PC

Pipe connection not included in supply, to be provided by customer

PE

Protective conductor required if the VARIFLUX 6000 is operated with a signal converter

that supplies a field current of > 125 mA / > 60 V. Wire

≥ 4mm

2

Cu (10 AWG), not included

with flowmeter, to be provided by customer

Y

Signal converter or connection box

8

Replacement of the separate flow sensors

Switch off power source before commencing work !

1) Note down terminal assignment before dismantling the “old” flow sensor.

2) Install the new flow sensor as described in the supplied installation instructions.

3) Make electrical connection at the signal converter as described in the installation and

operating instructions for the signal converter.

4) Specific calibration data are defined during factory calibration for each flow sensor, which are

indicated on the instrument nameplate.

This includes the primary constant GK and the magnetic field frequency.

These data need to be reset in the signal converter.

5) If the size of flow sensor is also different from the old one, the full-scale range Q

100%

and the

meter size will need to be reset.

6) After resetting the signal converter, carry out a zero point check.

7) If necessary, reset the internal electronic totalizer of the signal converter.