KROHNE PROFIFLUX IFS 5000 EN User Manual

Page 7

7

5

Installation in the pipeline

•

Installation material, refer to table on page 3.

•

Pipe flanges, and torques,

see Sect. 6, Page 7.

•

Pipe flange spacing (fitting dimension)

•

For arrangement of gaskets, see Sect. 7 “Grounding”.

•

Dimensions and order numbers of gaskets, see Sect. 9 and 11.

•

High-temperature pipelines

Where process temperatures exceed 100 °C/212 °F, provide for facilities to

compensate for longitudinal expansion on heat-up of the pipeline.

For short pipelines use resilient gaskets and

for long pipelines install flexible pipe elements (e.g. elbows).

•

Position of flanges

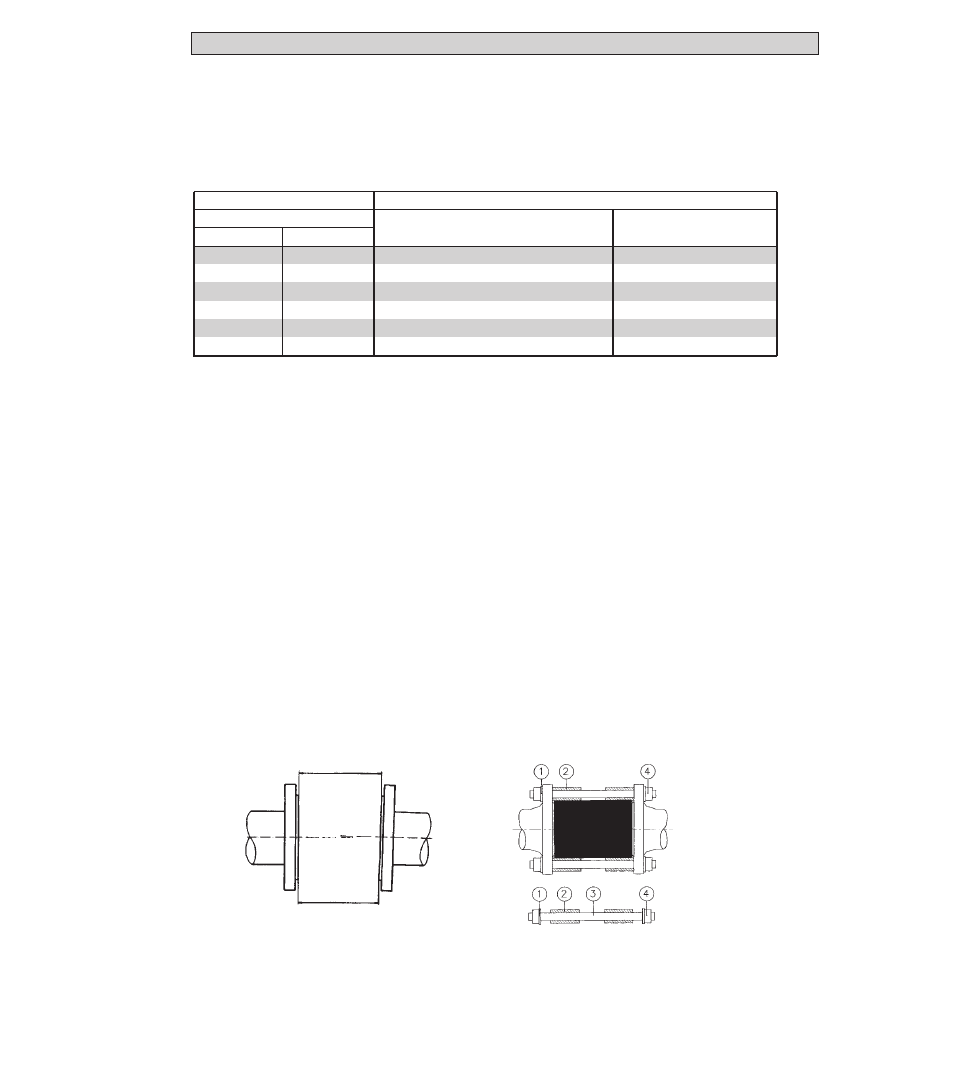

• Arrangement of centering sleeves

Install flowmeter in line with the pipe

1 washer

axis. Pipe flange faces must be

2 centering sleeve (

≥

DN 40 /

≥

1

1

/

2

”)

parallel to each other,

3 stud bolt

max. permissible deviation:

4 hex. nut

L

max

- L

min

≤

0,5 mm

≤

0.02”

L

max

L

min

1)

plus 2 x thickness of gasket D2 between grounding rings and pipe flanges,

gasket D2 not included with supply, customer supplied.

2)

incl. gasket D2 between grounding rings and pipe flanges.

3)

incl. gasket D3 between measuring tube and pipe flanges.

Flowmeter

Fitting dimensions “a” in mm (inch)

Meter size

with

without

DN mm

inch

grounding rings

grounding rings

2.5 - 15

1

/

10

” -

1

/

2

”

65 (2.56)

1)

–

25

1

68 (2.68)

2)

58 (2.28)

3)

40

1

1

/

2

”

93 (3.66)

2)

83 (3.27)

3)

50

2

113 (4.45)

2)

103 (4.06)

3)

80

3

163 (6.42)

2)

153 (6.02)

3)

100

4

213 (8.39)

2)

203 (7.99)

3)