KROHNE PROFIFLUX IFS 5000 EN User Manual

Page 11

11

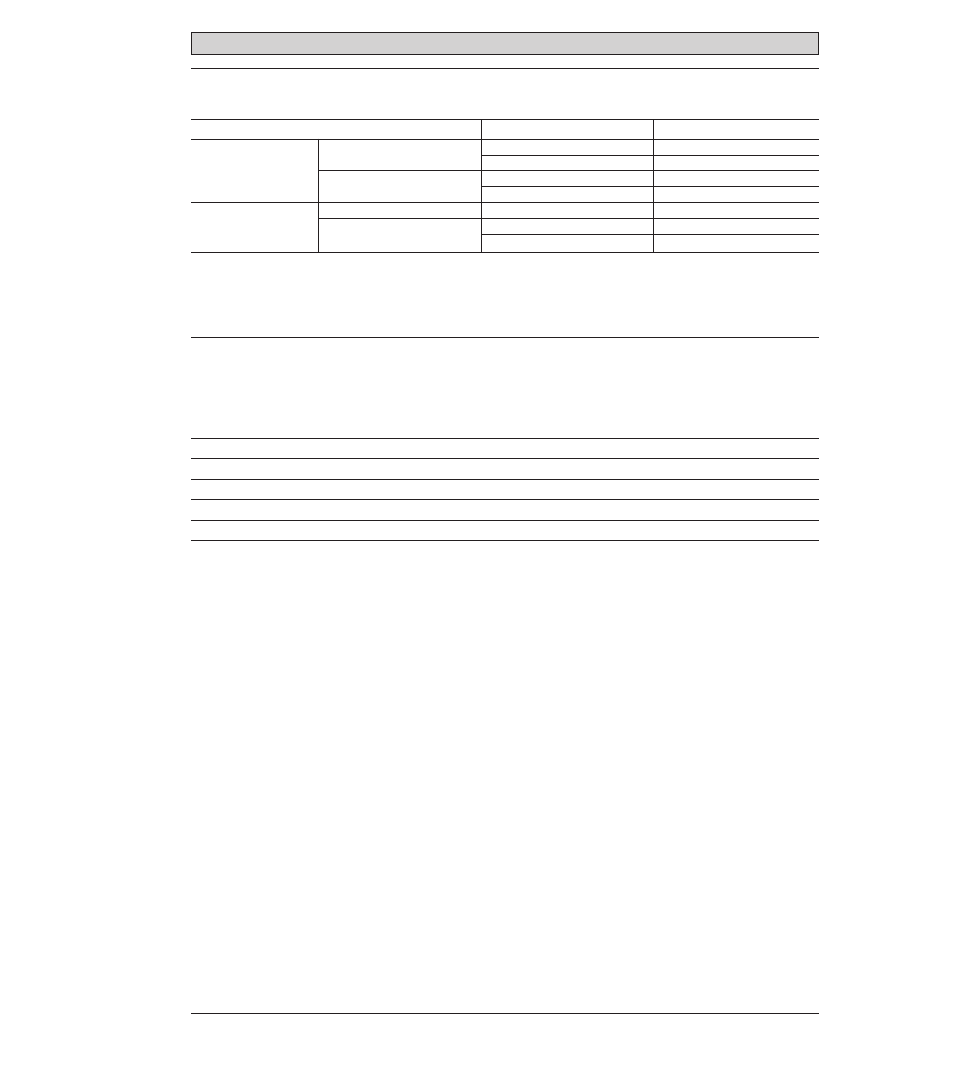

10. Technical data

Electrical conductivity

DN 2.5,

1

/

10

”

≥

10

µ

S/cm

≥

20

µ

S/cm for demineralized cold water

DN 4 - 100,

1

/

8

” - 4”

≥

5

µ

S/cm

Temperatures

Ambient temperature

Process temperature

Compact systems:

Standard

-25 to +60 °C (-13 to +140 °F)

-60 to +

0

60 °C (-76 to +140 °F)

-25 to +40 °C (-13 to +104 °F)

-60 to +140 °C (-76 to +284 °F)

EEx version

-25 to +60 °C (-13 to +140 °F)

-20 to +

0

60 °C (- 4 to +140 °F)

-25 to +40 °C (-13 to +104 °F)

-20 to +140 °C (- 4 to +284 °F)

IFS 5000 F (separate)

Standard

-25 to +60 °C (-13 to +140 °F)

-60 to +180 °C (-76 to +356 °F)

EEx version

-25 to +60 °C (-13 to +140 °F)

-20 to +

0

60 °C (- 4 to +140 °F)

-25 to +40 °C (-13 to +104 °F)

-20 to +150 °C (- 4 to +302 °F)

Temperature change

DN 2.5-15/

1

/

10

”-

1

/

2

”

DN 25-100/1”-4”

Temperature rising

in 10 minutes:

∆

T = 150 °C or 302 °F

∆

T = 150 °C or 302 °F

for sudden change:

∆

T = 120 °C or 248 °F

∆

T = 120 °C or 248 °F

Temperature falling

in 10 minutes:

∆

T = 120 °C or 248 °F

∆

T = 100 °C or 212 °F

for sudden change:

∆

T =

1

90 °C or 194 °F

∆

T =

1

80 °C or 176 °F

Max. operating pressure (at product temperature

≤

180 °C/

≤

356 °F)

DN 2.5 - 80

40 bar or 580 psig

DN 100

16 bar or 230 psig (option 25 bar/360 psig)

1

/

10

” - 4”

16 bar or 230 psig, for 150 lb pipe flanges

1

/

10

” - 3”

40 bar or 580 psig, for 300 lb pipe flanges (option)

4”

25 bar or 360 psig, for 300 lb pipe flanges (option)

Vacuum load

0 mbar abs. or 0 psia

Insulation class of field coils

H

Electrode design

fused-fitted electrodes

Power supply for field coils

max. 60 V from signal converter

Protection category (IEC 529 / EN 60 529)

IP 67, equivalent to NEMA 6

Materials

Measuring tube

Fused aluminium oxide, 99.7% Al

2

O

3

Electrodes

DN 2.5 - 15 /

1

/

10

” -

1

/

2

”

CERMET

DN 25 - 100 / 1” - 4”

Platin

Housing

DN 2.5 - 15 /

1

/

10

” -

1

/

2

”

stainless steel 1.4462/ Duplex

DN 25 - 100, 1” - 4”

stainless steel 1.4301 or SS 304 - AISI

Terminal box

Die-cast aluminium, with polyurethane finish

Grounding rings

stainless steel 1.4571 or SS 316 Ti - AISI, others on request

Gaskets between primary head

and grounding rings

DN 2.5 -

0

15 /

1

/

10

” -

1

/

2

”

Viton O-rings, optionally EPDM or Kalrez

DN 25 - 100, 1” - 4”

Gylon 3500 (beige) gaskets

(application range similar to that of PTFE),

optionally Chemotherm (graphite) gaskets

Gaskets between primary head or grounding rings

and pipe flanges (DN 25 to 100, 1” - 4”)

Gylon 3500 (beige) gaskets

(application range similar to that of PTFE),

optionally Chemotherm (graphite) gaskets

Centering material

DN 2.5 - 25 /

1

/

10

” - 1”

EPDM rings

DN 40 - 100 / 1

1

/

2

” - 4”

Rubber sleeves

Stud bolts

Steel electrogalvanized,

as option stainless steel 1.4301 or SS 304 - AISI

}