Connections, Load connection, general, Load connection, local sensing – KEPCO ATE (all models) QUICK START GUIDE User Manual

Page 4

4

228-1757

021012

KEPCO, INC. 131-38 SANFORD AVENUE FLUSHING, NY. 11355 U.S.A. TEL (718) 461-7000 FAX (718) 767-1102

http://www.kepcopower.com email: [email protected]

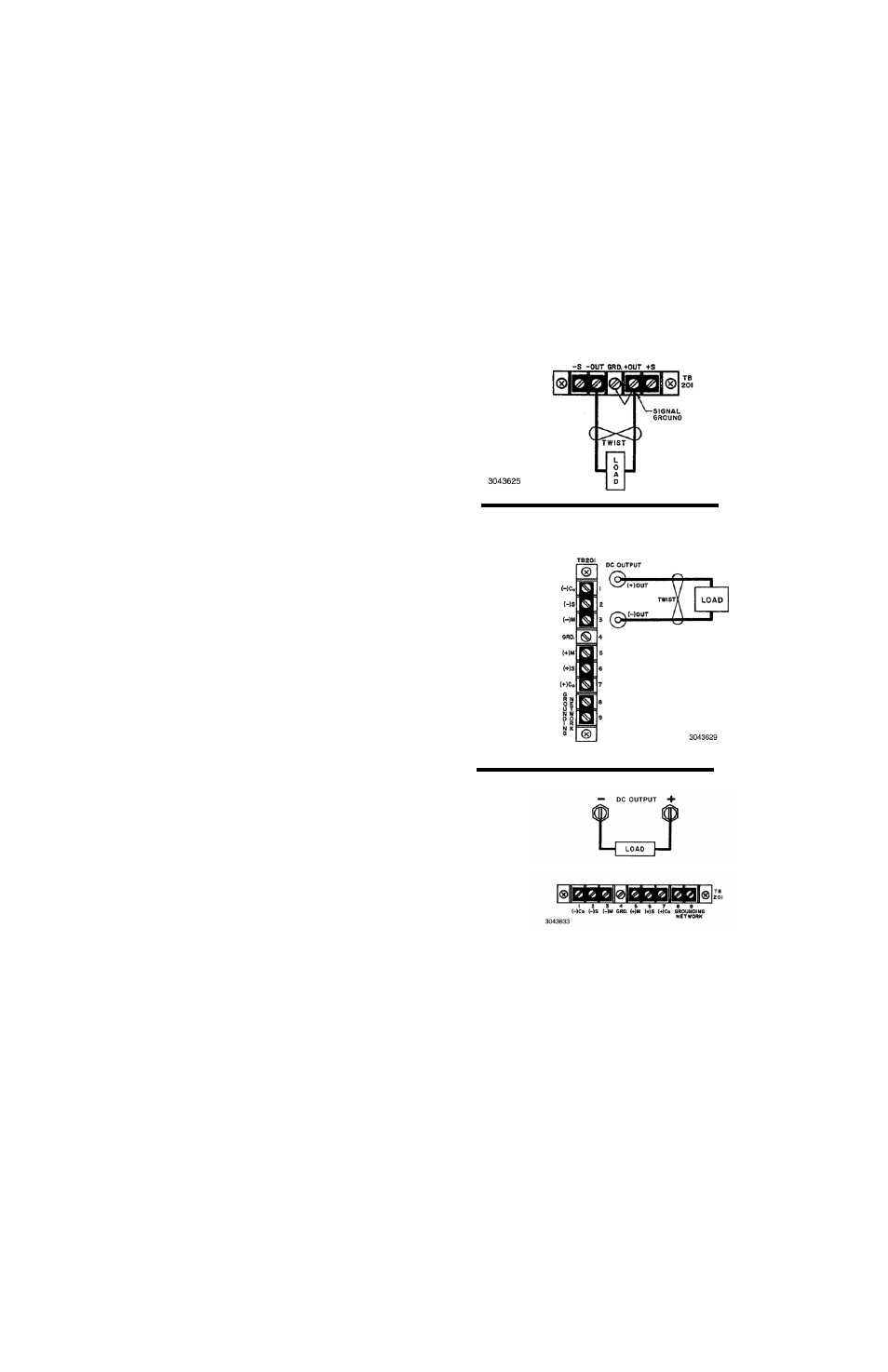

3.4. CONNECTIONS. Connections are made using

the rear panel terminations (see Figure 3).

3.4.1. LOAD CONNECTION, GENERAL. Connect the

load between –OUT and +OUT output power terminals at

the rear panel (see Figure 3. Sense connections are

required, either local or remote, must be used; other-

wise the unit will not operate.

See PAR. 3.4.2 for local sensing, see PAR. 3.4.3 for

remote sensing. Refer to the full Operator Manual (see

PAR. 1.1) if step changes in the load are expected if, for

example, the load is rapidly changing in value, or if the

power supply is programmed with step functions (square

wave, pulse, etc.) and maximum dynamic performance is

expected. If so, set the unit to “fast” mode by referring to

the full Operator Manual (see PAR. 1.1). Note that ripple

in “fast” mode will be higher than for the default “slow”

mode.

Terminals on the programming connector at the rear panel

and on the barrier strip (TB201) permit maximum flexibility

in power supply/load interface techniques. The program-

ming connector supplied has been pre-wired with jumpers

configured for front panel (local) control of output voltage,

output current and VP crowbar level with the power supply

operating in the “slow” mode.

The rear programming connector MUST be installed for

power supply to operate.

To configure the programming connector to allow remote

programming of the power supply, “fast mode,” or to use a

user-configured unwired PC 12 programming connector

(or to modify the programming connector supplied), refer

to the full Operator Manual (see PAR. 1.1). If the program-

ming connector jumper configuration has been altered,

make sure that all wires are properly soldered: loose con-

nections at the programming connector will cause the

power supply to malfunction.

3.4.2. LOAD CONNECTION, LOCAL SENSING. Figure

2 illustrates load connection using local sensing. Refer to

the full Operator Manual for load wire selection guidelines.

The output power leads should be twisted or tied together

to reduce EMI.

FIGURE 2. LOCAL SENSING

3/4 Rack

500W,

Full Rack

1000W

1/2 Rack

250W

1/4 Rack

50W, 100W