A.O. Smith BTH 120 - 250 User Manual

Page 8

8

IMPORTANT

The vent system must terminate so that proper clearances are maintained

as cited in local codes or the latest edition of the National Fuel Gas Code,

ANSI Z223.1,7.3.4e and 7.8a,b, as follows:

1. Do not terminate the exhaust vent terminal over public area where

condensate or vapor can cause nuisance or hazard.

2. For direct vent, the venting system shall terminate at least 1 foot below,

1 foot horizontally from or 1 foot above any door, window, or gravity air

inlet into building.

3. For horizontal the venting system shall terminate 4 foot below, 4 foot

horizontally from or 1 foot above any door, window, or gravity air inlet

into building.

4. The manufacturer also recommends the vent system terminations not

be installed closer than 3 feet from an inside corner of an L shaped

structure. And not less than 1 foot above grade or anticipated snow

level.

5. The vent termination shall not be mounted directly above or within 3 feet

horizontally from an oil tank vent or gas meter to avoid potential freeze-

up from condensation.

6. The vent shall terminate a minimum of 12" above expected snowfall

level to prevent blockage of vent termination.

Plan the vent system layout so that proper clearances are maintained from

plumbing and wiring.

Vent pipes serving power vented appliances are classified by building

codes as "vent connectors". Required clearances from combustible

materials must be provided in accordance with information in this manual

under LOCATION OF HEATER and CLEARANCES, and with National Fuel

Gas Code and local Codes.

IMPORTANT

Plan the layout of the vent system backwards from the vent termination to

the appliance.

WARNING

USE ONLY THE VENT TERMINALS SUPPLIED WITH THIS UNIT. TERMINATION

OF A VENT SYSTEM WITH A DEVICE OTHER THAN THE SUPPLIED VENT

TERMINATIONS WILL AFFECT SYSTEM PERFORMANCE AND RESULT IN A

SAFETY HAZARD.

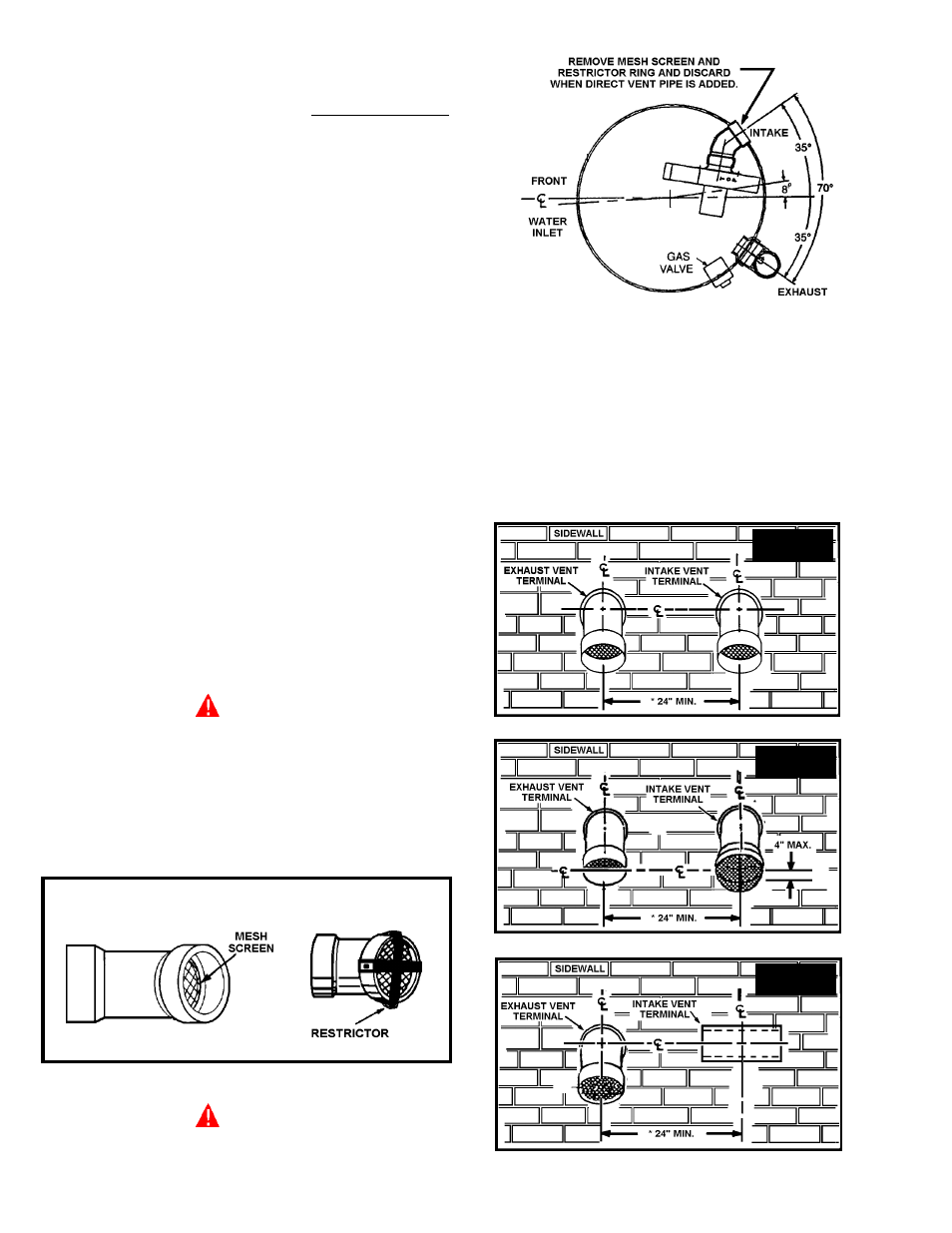

DIRECT VENTING

The air intake provided on the unit contains a mesh screen (see Figure 7)

to prevent large particles from entering the unit.

FIGURE 7

WARNING

WHEN THE UNIT IS TO BE SETUP AS A DIRECT VENT, THE MESH SCREEN

MUST BE REMOVED. THE INLET VENT PIPE MAY THEN BE GLUED TO THE

AIR INTAKE (see Figure 8) PROVIDED ON THE UNIT.

FIGURE 8

DIRECT VENT TERMINAL INSTALLATION

IMPORTANT

THIS UNIT CONSISTS OF TWO VENT TERMINALS - AN INTAKE VENT

TERMINAL AND AN EXHAUST VENT TERMINAL. THE INTAKE VENT

TERMINAL IS A 3" 45°PVC ELBOW (OR 3" PVC TEE FOR BTH 250) WITH A

MESH WIRE SCREEN AND THE EXHAUST VENT TERMINAL IS A 3" 45°PVC

ELBOW WITH A MESH WIRE SCREEN.

FIGURE 9

3" 45° PVC ELBOW WITH MESH SCREEN

BTH 120

BTH 150

& 199

BTH 250