Operation, Self diagnostic controller – A.O. Smith BTH 120 - 250 User Manual

Page 15

15

OPERATION

SEQUENCE OF OPERATION

Typical Control/Appliance Operating Sequence

1. When the control is powered, it should first display 0, then the input

line voltage (120), the calibration setting (12), then the actual water

temperature in the tank.

2. If the control determines that the actual water temperature inside the

tank is below the programmed temperature setpoint less the differential,

a call for heat is activated.

3. The control then performs selected system diagnostic checks. This

includes confirming the proper state of the air switch and ECO limit

device.

4. If all checks are successfully passed, the combustion blower is

energized for the pre-purge cycle.

5. When the pre-purge cycle is complete, power is applied to the ignitor

element for the ignitor warm-up period.

6. At the conclusion of the igniter warm-up period, the gas valve will open,

allowing gas to enter the burner chamber.

7. The igniter will remain on for a short predetermined time period, then will

be turned off.

8. After an additional 2 seconds, the control will monitor the flame sense

probe to confirm a flame is present. If a flame is not verified within this

time period, the gas valve will immediately be closed, and the blower will

continue to run for approximately 10 seconds. The control will then

return to step 2.

9. If a flame is confirmed, the control will enter the heating mode where it

will continue heating the tank water until the setpoint temperature plus

differential is reached. At this point, the gas valve is closed and the

control enters the post-purge cycle.

10.The combustion blower will run for the duration of the post purge cycle

to purge the system of all combustion gases. When the post purge

cycle is complete, the blower is de-energized and will coast to a stop.

11. The control will now enter the idle state while continuing to monitor the

internal tank water temperature and the state of other system devices.

If the temperature drops below the setpoint value less differential, the

control will automatically return to step 2 and repeat the entire operating

cycle. During this idle state, if the control detects an improper operating

state for external devices such as the ECO switch, vent switch, pressure

switch, etc., the appropriate LED(s) on the Display Board will be

illuminated indicating the nature of the fault.

SELF DIAGNOSTIC CONTROLLER

This controller is designed for ignition lockout after three consecutive failed

attempts to light. If lockout occurs, the display lights will match Figure 18.

Along with this, a numeric message will appear in the display. The following

list of ERROR CODES illustrates possible numeric failures.

FIGURE 18

GAS VALVE LED FLASHING

This condition results from a failure to establish burner ignition after three

successive trials. In such cases:

1. Investigate the possible cause and remedy any observations.

2. Momentarily depress the button on the display panel to reset the lockout

condition.

3. Confirm proper appliance operation.

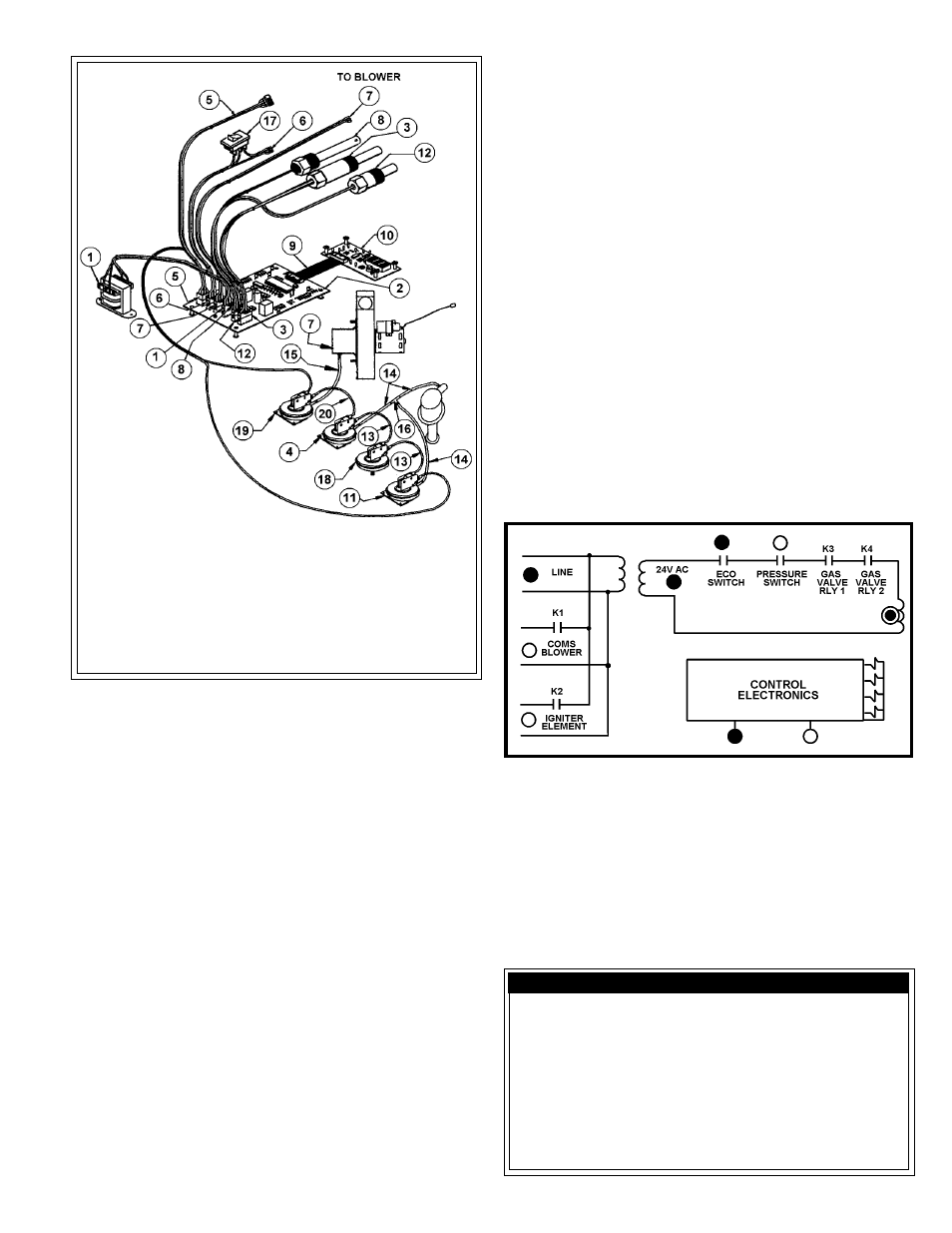

FIGURE 17

14. Tubing-Pressure

15. Tubing-Pressure

16. Connector-Tubing

17. Switch-On/Off

18. Low Gas Pressure

Switch

19. Bocked Inlet Switch

20. Wire Assembly-Air

Flow Switch

ITEM DESCRIPTION

1. Transformer

2. Control Board

3. E.C.O./Temperature Probe

4. Blower Proving Air Switch

5. Low Voltage Cable Assembly

6. Line Voltage Cable Assembly

7. Blower/Motor Assembly

8. Igniter Assembly

9. Cable To Control Display Board

10. Control Display Board

11. Blocked Outlet Exhaust Switch

12. Lower Temperature Probe

13. Wire Assembly-Gas Pressure

Switch

Possible Cause

Remedy

1. Burner ground wire broken

1. Check wire and connection

or corroded

at burner

2. Connectors unplugged

2. Check connections

3. Igniter broken

3. Replace igniter

4. Flame probe faulty

4. Replace flame probe

5. Gas shut off

5. Turn on gas supply

6. Clogged gas valve

6. Replace gas valve

7. Faulty gas valve

7. Replace gas valve

8. Defective control

8. Replace control

9. Burner improperly adjusted

9. Adjust burner

10. Dirty burner

10. Clean burner