7 remote mounting installation – Detcon FP-524D INSTRUCTION MANUAL User Manual

Page 14

Model FP-524D

FP-524D Instruction Manual

Rev. 1.4

Page 10 of 39

d) Plug the Transmitter Module into the connector PCB and replace the junction box cover.

NOTE: A 6-32 or 8-32 threaded exterior ground point is provided on most junction boxes for

an external ground. If the Sensor Assembly is not mechanically grounded, an external ground

strap must be used to ensure that the sensor is electrically grounded.

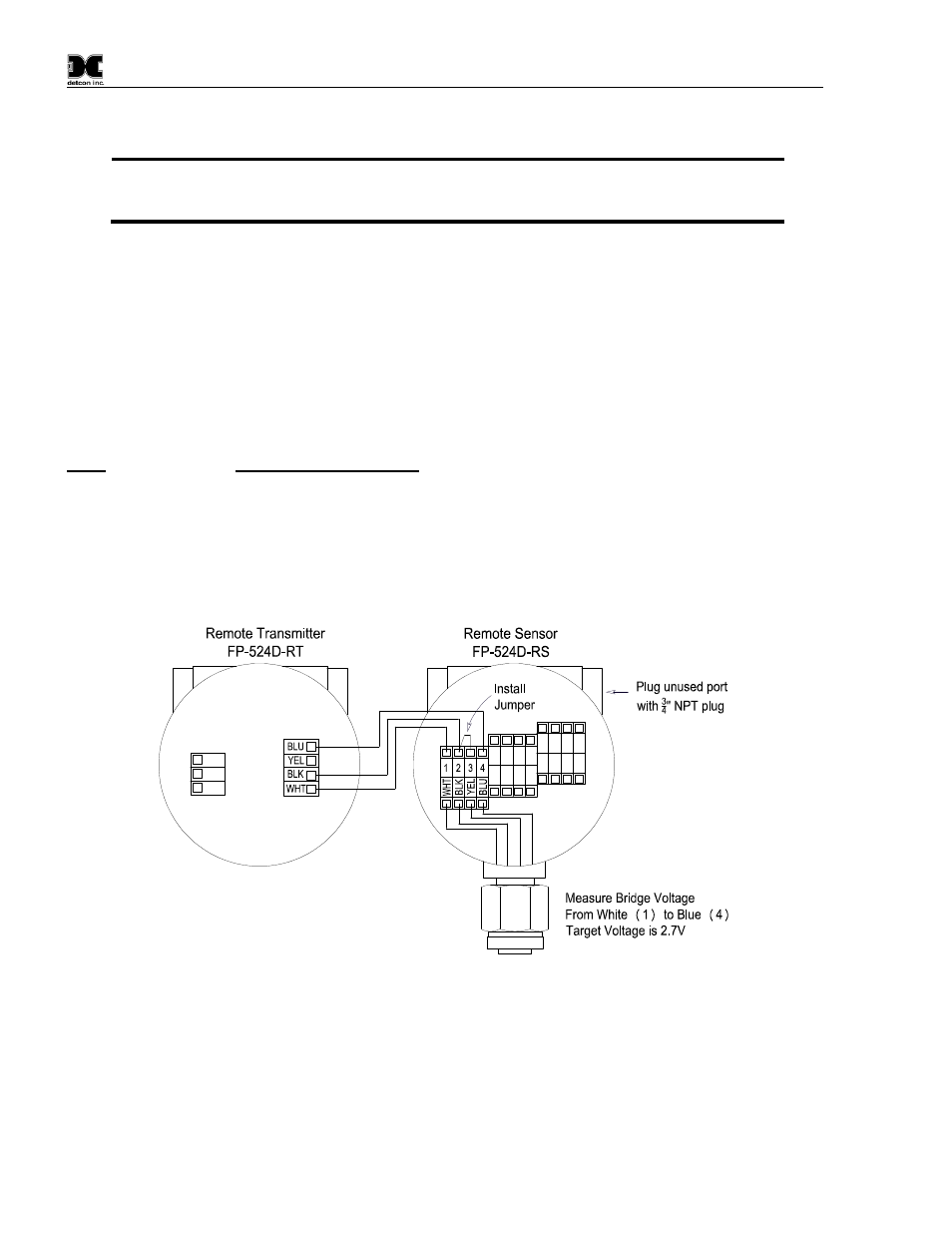

2.7 Remote Mounting Installation

Some sensor mounting applications require that the gas sensor head be remotely mounted away from the

sensor transmitter. This is usually true in instances where the gas sensor head must be mounted in a location

that is difficult to access. Such a location creates problems for maintenance and calibration activities. Detcon

provides the FP-524D sensor in a remote-mount configuration in which the sensor (Model FP-524D-RS) and

the transmitter (Model FP-524D-RT) are provided in their own condulet housing and are interfaced together

with a three conductor cable. There is a limit 0.5 ohm maximum resistance drop per wire over the separation

distance.

AWG

Maximum Separation (feet)

20

50

18

75

16

125

14

175

Reference Figure 12 for wiring diagram. Also note the jumper that is required on the remote sensor connector

board. Failure to install this jumper will cause a sensor fault condition.

Figure 12 Remote Sensor Wiring Diagram

2.7.1

Bridge Voltage Adjustment

When a sensor is remote mounted, consideration must be given to the lengths of cable used and how it affects

the sensor bridge voltage. Differing lengths of cables will have varying amounts of resistance which will shift

the sensor bridge voltage. Because of this, the bridge voltage will need to be adjusted after initial power up.