4 mounting installation, 5 electrical installation, Figure 9 typical outline and mounting dimensions – Detcon FP-524D INSTRUCTION MANUAL User Manual

Page 11

Model FP-524D

FP-524D Instruction Manual

Rev. 1.4

Page 7 of 39

the active detector’s catalytic ability and cause a permanent reduction in the span sensitivity. Examples of

typical poisons are: silicone oils and greases, siloxanes (HMDS), H

2

S, anti-knock petrol additives, and

phosphate esters. Activated carbon filters can be used to provide additional protection from poisoning in most

cases.

The presence of such inhibitors and poisons in an area does not preclude the use of this sensor technology,

although it is likely that the sensor lifetime will be shorter as a result. Use of this sensor in these environments

may require more frequent calibration checks to ensure safe system performance.

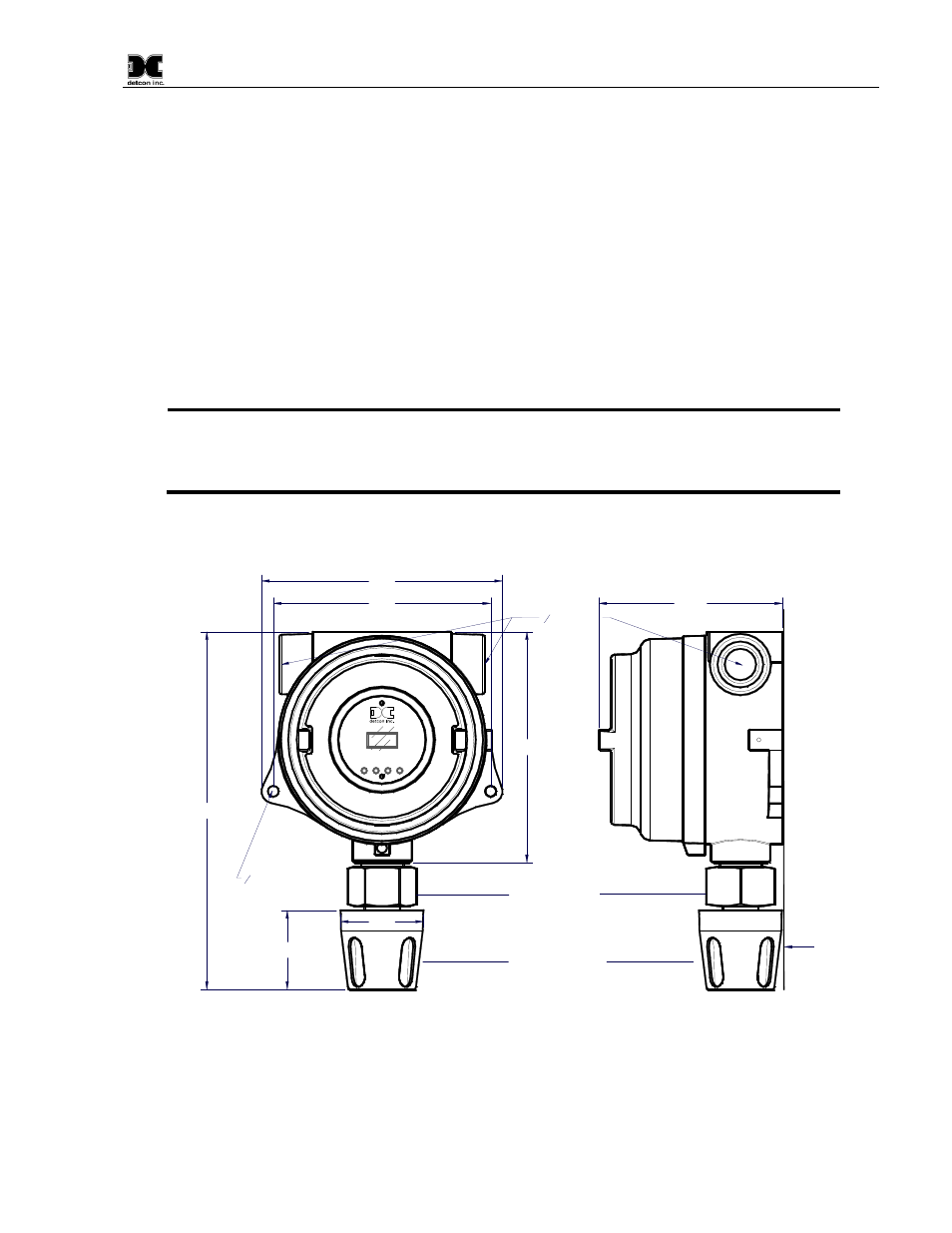

2.4 Mounting Installation

The FP-524D should be vertically oriented so that the sensor points straight downward. The explosion-proof

enclosure or junction box would then typically be mounted on a wall or pole (See Figure 9). Detcon provides

a selection of standard junction boxes in both Aluminum and Stainless Steel.

NOTE: Do not use Teflon Tape or any other type of Pipe Thread material on the ¾” threads

unless the unit is mounted in a severe or harsh environment. Metal-on-metal contact must be

maintained to provide a solid electrical ground path. If Teflon Tape is used the Sensor must be

externally grounded using a ground strap.

When mounting on a pole, secure the Junction Box to a suitable mounting plate and attach the mounting plate

to the pole using U-Bolts. (Pole-Mounting brackets for Detcon Junction Box’s are available separately.)

PGM

1

PGM

2

MODEL

FP-524D

HOUSTON, TEXAS

FLT

1

2

CAL

MicroSafe

LEL Gas Sensor

ALM ALM

TM

5.5"

6.1"

9.03"

2"

5.8"

4.65"

3

4

NPT Ports

1

4

" mounting holes

W

a

ll

(o

r

o

th

e

r

m

o

u

n

ti

n

g

s

u

rf

a

c

e

)

LEL Sensor

Splash Guard

2.1"

Figure 9 Typical Outline and Mounting Dimensions

2.5 Electrical Installation

The Sensor Assembly should be installed in accordance with local electrical codes. The sensor assemblies are

CSA/NRTL approved (US and Canada) for Class I, Division 1, Groups B, C, & D area classifications.