Van Air Systems FD-250 User Manual

Blast pak, Warning, Operation and maintenance instructions for

PAGE 1

DO NOT OPERATE THIS SYSTEM ABOVE MAXIMUM WORKING

PRESSURE (MWP) AND/OR MAXIMUM OPERATING TEMPERA-

TURE (

O

F) SHOWN ON THE VESSEL ASME DATA PLATE.

THIS ASME CODE VESSEL MUST BE PROTECTED BY A

PRESSURE RELIEF VALVE. Refer to OSHA 1910.169 Par.

b, Sub. Par (3) and ASME Boiler and Pressure Vessel Code,

Section VIII, Division 1, UG-125 through UG-136. Also comply

with all applicable state and local codes.

DO NOT ATTEMPT TO REMOVE OR REPAIR ANY PART OF THE

SYSTEM UNTIL IT IS COMPLETELY DEPRESSURIZED. SERI-

OUS PERSONAL INJURY MAY RESULT IF THIS SAFETY RULE

IS NOT FOLLOWED.

DO NOT WELD, GRIND, OR SAND VESSEL, THIS WILL MAKE

IT UNSAFE TO OPERATE. (Note: Any alteration to the vessel

will void the ASME Code Certification and the warranty.)

INSPECT VESSEL, INSIDE AND OUT, REGULARLY FOR

BULGES, CORROSION, DENTS, GOUGES, LEAKS OR SIGNS

OF FIRE. IF DAMAGED, REMOVE FROM SERVICE IMMEDI-

ATELY AND NOTIFY YOUR CERTIFYING AUTHORITY.

DO NOT TRY TO TIGHTEN A LEAKING HATCH COVER. IM-

MEDIATELY SHUT OFF THE AIR SUPPLY AND DEPRESSUR-

IZE THE SYSTEM.

DO NOT ATTEMPT TO REMOVE THE HATCH COVER UNTIL

THE SYSTEM IS COMPLETELY DEPRESSURIZED. WHEN

THE VESSEL PRESSURE IS REDUCED TO ZERO, THE HATCH

COVER CAN BE REMOVED BY HAND.

INSTALL A NEW GASKET EVERY TIME THE HATCH COVER

IS REMOVED, OR AT LEAST ONCE PER YEAR. INSPECT THE

COVER AND SEALING SURFACE FOR DAMAGE SUCH AS

CORROSION, CRACKS, OR DISTORTION. IF THERE IS ANY

DAMAGE, REPLACE COVER. REPLACE THE HATCH COVER

EVERY FIVE YEARS REGARDLESS OF CONDITION. USE VAN

AIR AUTHORIZED PARTS ONLY.

DO NOT USE POWER TOOLS OR CHEATER BARS TO

TIGHTEN THE NUT ON THE HATCH COVER. TOO MUCH

FORCE CAN DISTORT THE COVER AND/OR THE GASKET. IF

DAMAGED BY OVERTIGHTENING, THE COVER CAN BLOW

OUT AND CAUSE SERIOUS INJURY. (Note: Tighten the nut

until it is snug. When the vessel is pressurized, the pressure

on the cover will complete the seal.)

THE USE OF CHEMICALS OTHER THAN VAN AIR DESICCANT

WILL VOID THE WARRANTY ON THE BLAST PAK.

October 2010

P/N 32-0294

Rev A

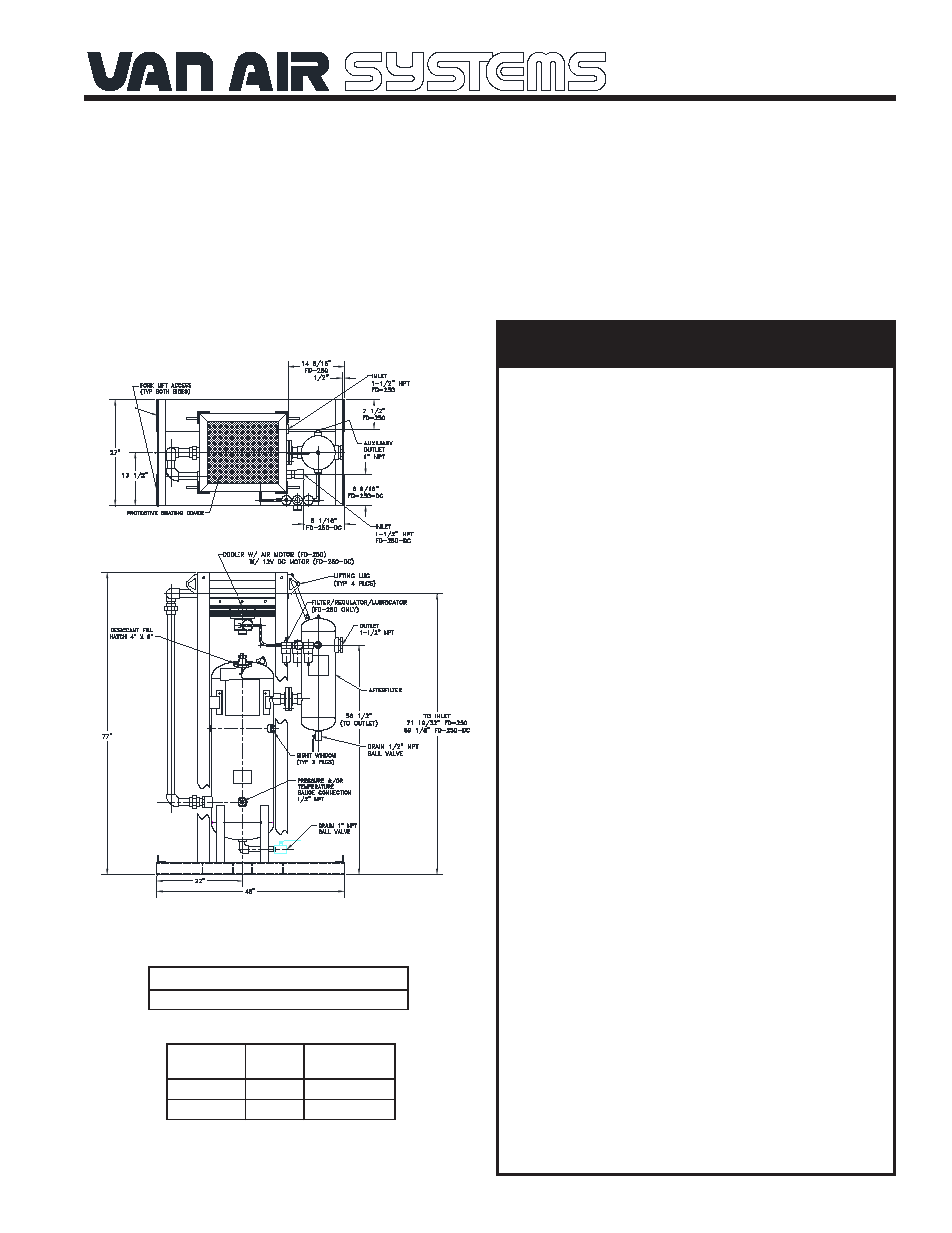

OPERATION AND MAINTENANCE INSTRUCTIONS

FOR

BLAST PAK

PACKAGED COMPRESSED AIR TREATMENT SYSTEM

MODELS:

FD-250 & FD-250-DC

WARNING

REGULATOR SETTING FOR AIR MOTOR

22 PSIG TO GET 3450 RPM

MODEL

FD-250

FD-250-DC

WEIGHT

660 lbs

675 lbs

DRY-O-LITE

DESICCANT *

250 lbs

250lbs

* - ORIGINAL FILL OF DESICCANT SUPPLIED - CUSTOMER

TO INSTALL