Van Air Systems Sentinel MDV-400L Series User Manual

Sentinel, Model mdv400l, Installation, operation & maintenance instructions

PAGE 1

October 2011

P/N 432-10035-B

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

SENTINEL

®

MOTORIZED BALL VALVE WITH ADJUSTABLE CYCLE TIME

Model MDV400L

WARNINGS

DO NOT REMOVE OR REPLACE ANY PART OF THE PRODUCT WHILE IT IS UNDER PRESSURE. SERIOUS PER-

SONAL INJURY AND/OR DAMAGE TO THE PRODUCT MAY RESULT.

DO NOT OPERATE THE PRODUCT IF THERE ARE ANY PRESSURE LEAKS. IF A LEAK IS PRESENT, THE PRODUCT

MAY BE UNSAFE TO OPERATE. REMOVE THE PRODUCT FROM SERVICE IMMEDIATELY.

DO NOT OPERATE THIS PRODUCT ABOVE ITS MAXIMUM OPERATING PRESSURE AND/OR TEMPERATURE.

WHEN INSTALLING THIS PRODUCT, BE SURE TO COMPLY WITH ALL LOCAL, STATE, INTERNATIONAL, AND/OR

GOVERNMENT LAWS, RULES, REGULATIONS AND CODES APPLICABLE TO YOUR INSTALLATION.

DO NOT INSTALL THIS PRODUCT IN A MANNER THAT DISCHARGES TOWARDS PEOPLE OR EQUIPMENT. SERI-

OUS INJURY AND/OR DAMAGE MAY RESULT.

PROPER DISPOSAL OF DRAINED LIQUIDS THROUGH THIS PRODUCT ARE THE RESPONSIBILITY OF THE USER.

Thank you for buying this product.

For optimum performance and safety, please read and understand all instructions before installation.

Personnel must use safe working practices and observe all applicable local and international regulations, safety, health and legal requirements when

installing and operating this product. Improper operation or maintenance of this product could be potentially dangerous resulting in an accident

causing injury or death. Van Air Systems cannot anticipate every possible circumstance, which represents a potential hazard. The Warnings in this

manual cover the most common potential hazards and are therefore not all-inclusive. The installation and maintenance of this product must be in

strict accordance with this instruction manual or the warranty will be invalidated

.

•

•

•

•

•

•

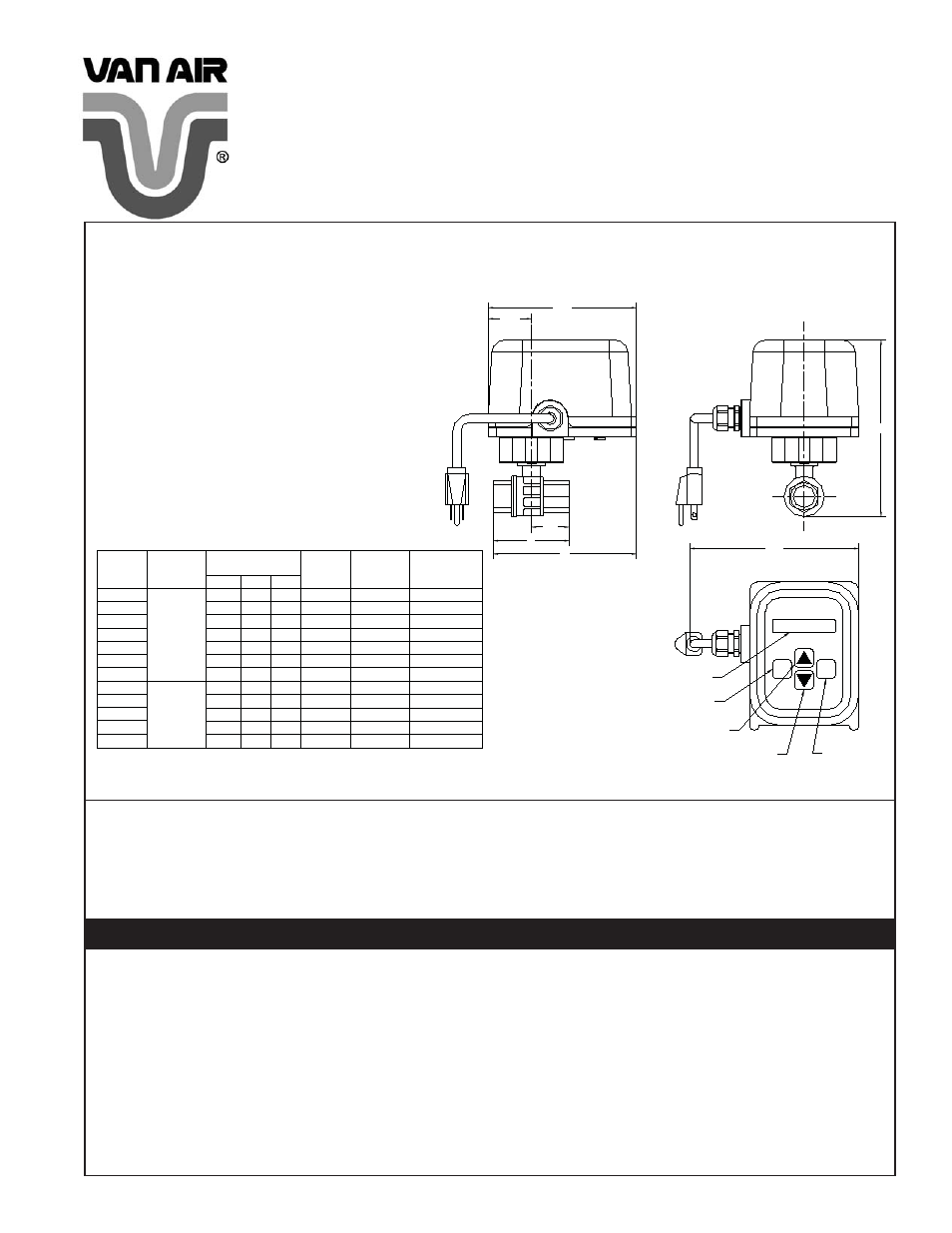

FIGURE 1

6.06

6.58

6.94

5.75

5.58

A

8.83

3.56

5.31

4.60

2.93

2.60

8.39

8.16

DIMENSIONS

B

10.65

12.96

1 1/2"

2"

3/4"

1/2"

1"

BRASS

1"

3/4"

2-1/2"

1/2"

3"

STAINLESS

STEEL

VALVE

SIZE

(NPT)

VALVE

MATERIAL

WEIGHT

(LBS)

ACTUATOR

TORQUE

(IN/LBS)

300

150*

150*

150*

150*

9.66

8.67

8.18

21.16

16.14

5.78

6.00

5.68

7.73

7.33

3.43

3.00

2.80

6.89

6.10

150*

150*

150*

600

600

B

C

7.51

10.86

11.65

7.78

7.93

8.43

9.13

7.83

9.72

7.02

C

6.81

6.00

1.72

B/2

1 1/2"

2"

10.23

9.48

6.51

6.98

5.40

4.46

14.88

11.65

150*

300

A

600

350

475

780

38

71

110

143

205

19

34

52

FLOW

COEFFICIENT

CV

(316 SS)

* ACTUATOR TORQUE FOR THESE UNITS WITH DC VOLTAGE IS 300 IN/LBS.

LCD DISPLAY

ENTER

ENTER

MODE

MODE

MODE BUTTON

ADJUST UP

BUTTON

ADJUST DOWN

BUTTON

ENTER BUTTON

NOTES:

1. RATED PRESSURE: BRASS

600 PSIG COLD WOG.

SS

900 PSIG COLD WOG

2. VALVES ARE FULL PORT 2 PIECE BALL VALVES

3. AVAILABLE ELECTRICAL: -115VAC-1PH-50/60HZ, MAX CURRENT: 1.7 AMPS

-230VAC-1PH-50/60HZ, MAX CURRENT: 0.9 AMPS

-12VDC, MAX CURRENT: 1.7 AMPS

-24VDC, MAX CURRENT: 0.9 AMPS

(DC VOLTAGE UNITS ARE SUPPLIED WITH POWER CORD BUT WITHOUT PLUG)

4. TIME SETTINGS:

OPEN TIME: 1 SECOND TO 99 MINUTES & 59 SECONDS AT 1 SECOND INCREMENTS.

CLOSED TIME: 1 MINUTE TO 99 HOURS & 59 MINUTES AT 1 MINUTE INCREMENTS.

5. ENCLOSURE RATING:

NEMA 1

6. AMBIENT TEMPERATURE OPERATING RANGE:

40 TO 120°F

†

7. VALVE INTERNAL MATERIALS:

BRASS VALVES;

BALL-CHROME PLATED BRASS

STEM-BRASS, NICKEL PLATED

SEAT-RTFE

316 SS VALVES;

BALL-316SS

STEM-316SS

SEATS-PTFE/TFM

† NOTE: Display may be sluggish at temperatures below 40°F and darkened at

temperatures approaching 110°F (for best results, keep out of direct sunlight).