Operation – Van Air Systems ID35 User Manual

Page 3

PAGE 3

2.2-E DESICCANT INSTALLATION

IMPORTANT

This dryer was shipped WITH the desiccant installed.

See Section 3.3 of this manual for desiccant replacement.

SECTION 2

INSTALLATION

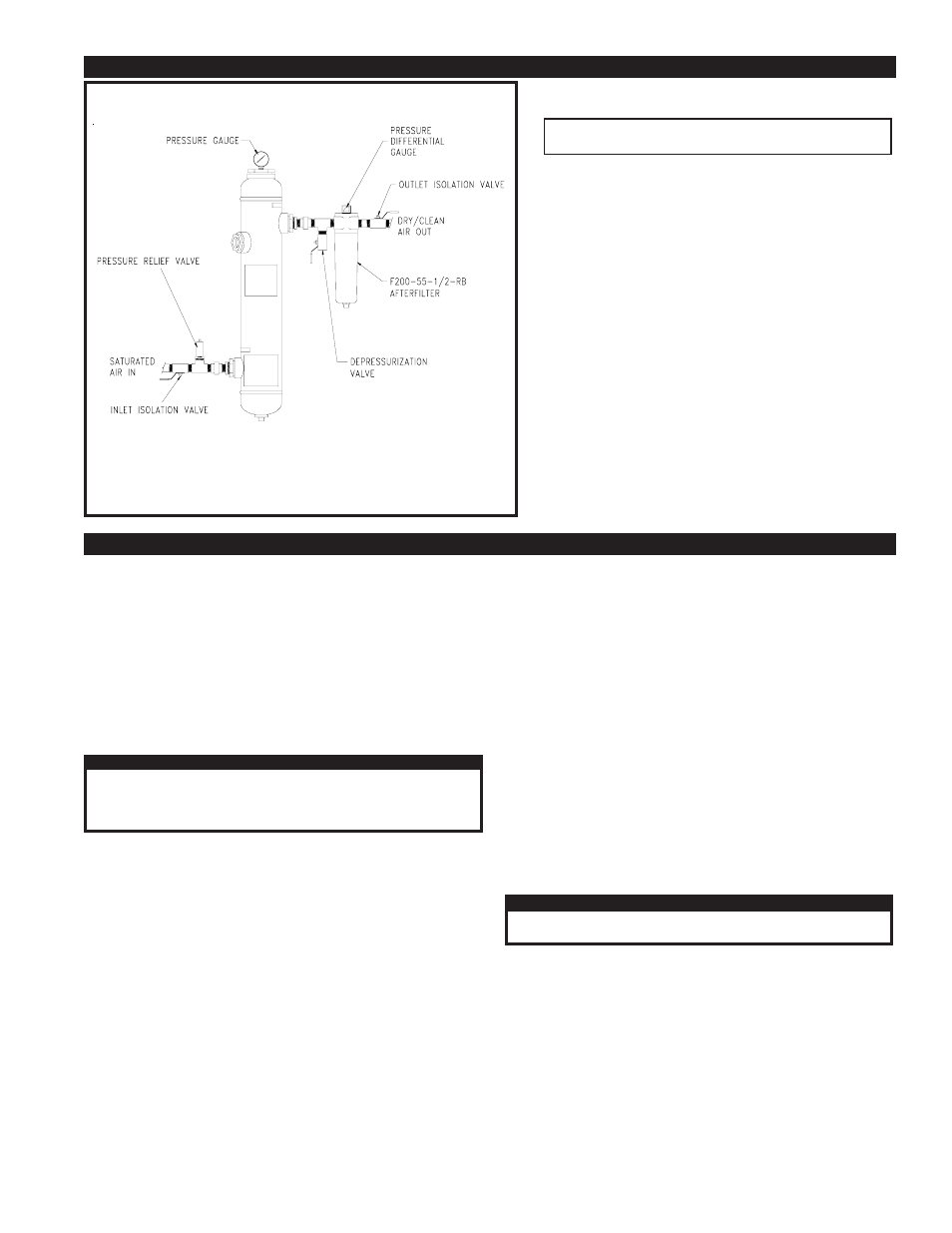

FIGURE 3 RECOMMENDED INSTALLATION DRAWING

NOTE:

ITEMS CALLED OUT IN THIS DRAWING

ARE NOT SUPPLIED WITH THE DRYER.

REFERENCE FIGURE 1 FOR ITEMS

INCLUDED WITH DRYER.

SECTION 3

OPERATION

3.3 REPLACING THE ADSORBENT DESICCANT

Close the inlet and outlet isolation valves (if installed).

Slowly open the depressurization valve to completely depressurize the

unit.

Remove the desiccant drain plug from the bottom of the vessel and

drain the old desiccant.

Replace the drain plug. Use pipe thread compound as needed.

Remove the fill port plug from the top of the vessel.

Fill the vessel with adsorbent desiccant. It takes approximately 8

pounds of indicating silica gel to fill the vessel.

Replace the fill port plug.

Start up the dryer per section 3.1.

3.3 USING THE SIGHT WINDOW

WARNING

IF SIGHT WINDOW IS DAMAGED IN ANY WAY, REPLACE IT

IMMEDIATELY WITH VAN AIR PART NO. 26-0104 only.

When using indicating silica gel, look into the sight window to check the

color of the desiccant bed. Pink silica gel is moist and blue silica gel is

dry. Replace the silica gel when the sight window shows pink.

3.1 START UP PROCEDURES

Make sure all isolation valves are closed.

Pressurize the system.

SLOWLY open the inlet isolation valve to bring the unit up to line

pressure.

SLOWLY open the outlet isolation valve to put the unit on stream.

If the vessel was installed without isolation valves, SLOWLY pressurize

the air system.

CAUTION

Make sure that the dryer is not subjected to sudden flow

surges. Always open valves slowly to permit gradual

equalization of pressure between the dryer and the air supply

lines.

3.2 OPERATING THE DRYER

On a new installation, drain all downstream traps for several days (or

until no water is evident) after dryer is installed. This period is required

to dry out any accumulated water in the compressed air system. Once

the water is removed, the downstream traps should not need to be

drained again.

If silica gel desiccant is used in the vessel, it should be replaced when

the color in the sight window changes. Pink silica gel is moist and blue

silica gel is dry.

If other adsorbents are used, they should be replaced on a scheduled

basis, or when downstream measurement equipment indicates it.