Van Air Systems FD400-FD1600 blast-pak User Manual

Page 4

PAGE 4

FD-400 QTY

1

1

2

1

1

1

-

-

1

-

-

1

-

-

1

8

-

1

-

-

1

1

1

1

1

1

-

1

1

FD-800 QTY

1

1

2

1

1

-

1

-

-

1

-

-

1

-

1

10

1

-

1

-

1

1

1

1

1

1

1

1

1

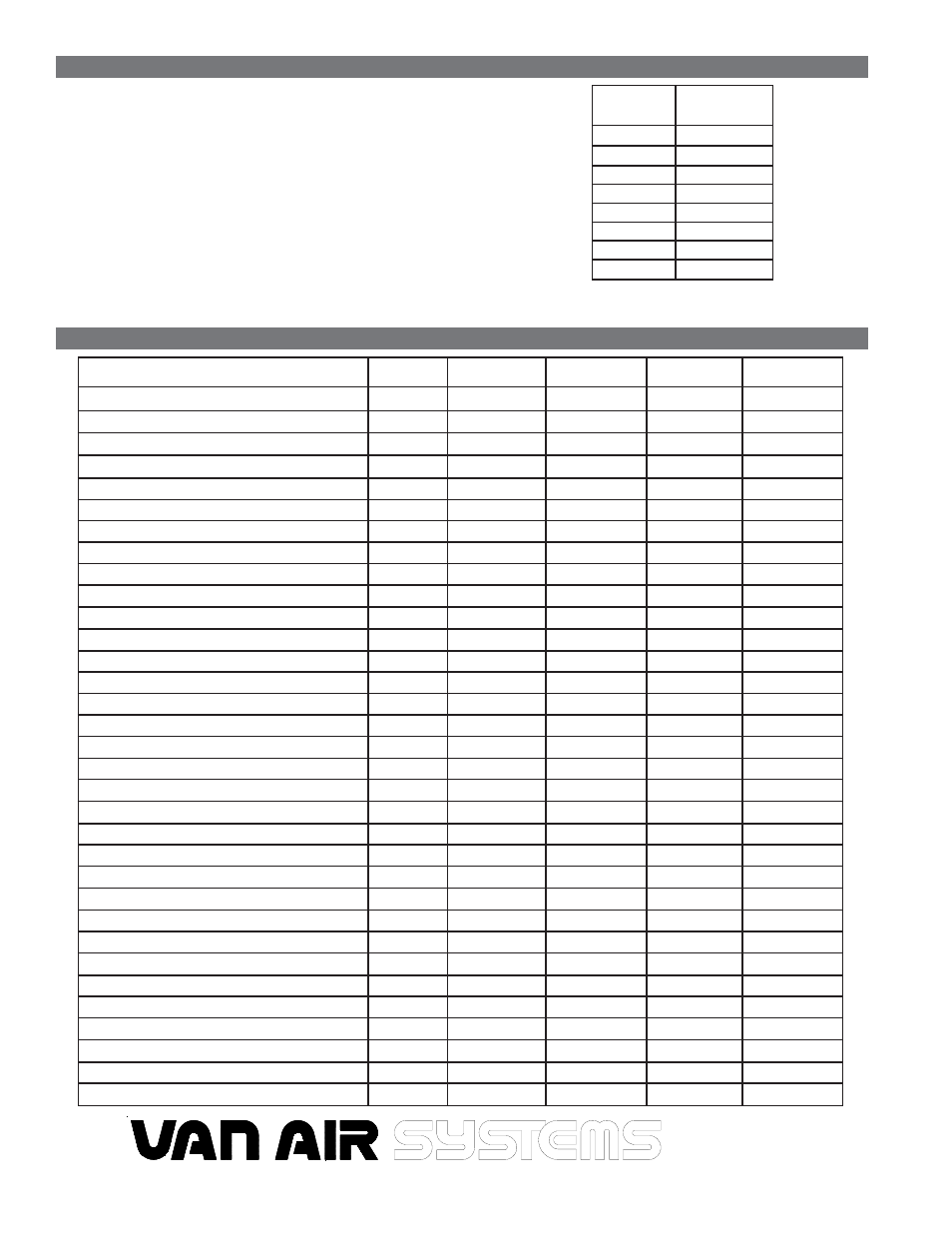

SECTION 5

MAINTENANCE

For special applications requiring desiccants other than DRY-O-LITE,

consult factory.

FLOW

SCFM

200

400

600

800

1000

1200

1400

1600

DRY-O-LITE

LBS/YEAR

264

528

792

1056

1320

1584

1848

2112

SECTION 6

REPLACEMENT PARTS

DESCRIPTION

Gasket for 4"x6" hatch cover

Hatch Cover, 4" x 6"

Sight Window

Manual Drain Valve 1" NPT

Manual Drain Valve 1/2" NPT

Air Motor for Aftercooler

Air Motor for Aftercooler

Air Motor for Aftercooler

Filter-Regulator-Lubricator

Filter-Regulator-Lubricator

Filter-Regulator-Lubricator

Element for FRL

Element for FRL

Element for FRL

Oil for Lubricator (Quart)

DESICCANT

DRY-O-LITE Desiccant, 50 LB BAG

DRY-O-LITE Desiccant, 506 LB DRUM

OPTIONAL EQUIPMENT

Relief Valve 3/4" NPT 200# set pressure

Relief Valve 1-1/2" NPT 200# set pressure

Relief Valve 1-1/2" NPT 175# set pressure

Pressure gauge kit

Pressure gauge only

Temperature gauge kit

Temperature gauge only

Thermowell only

Combination pressure/temperature gauge

HLA-120 High level alarm kit

Automatic drain valve PDV-500T

White touch up paint (9 oz. spray can)

PART NO.

18-0394

46-3003

26-0104

14-0451

14-0450

26-6277

34-0926

34-0925

26-7039

26-7009

26-6836

26-7056

26-7027

26-7030

26-7032

33-0311

33-0203

14-1800

14-2307

14-2308

29-0252

29-0151

29-0326

29-0108

29-0107

29-0200

26-3667

39-0284

45-0152

To use the chart, first determine the SCFM that is being processed

through the Blast Pak. Then locate the nearest flow rate listed on the

chart and interpolate as needed.

The desiccant bed level should be maintained to at least the sight

window level at all times to ensure optimum drying capabilities.

(This chart is based on 1 shift for a one year period (2,000 hours)@

100 psig inlet pressure and 75

o

F inlet temperature into dryer vessel,

100% RH.)

FD-1200 QTY

1

1

2

1

1

-

1

-

-

1

-

-

1

-

1

15

2

-

1

-

1

1

1

1

1

1

1

1

1

FD-1600 QTY

1

1

2

1

1

-

-

1

-

-

1

-

-

1

1

20

2

-

-

1

1

1

1

1

1

1

1

1

1

The consumption rate is proportional to the moisture loading. Each

20

o

F increase in inlet temperature changes the moisture loading by a

factor of nearly 2:1.

2950 Mechanic Street

Lake City, PA 16423-2095

Phone: 814-774-2631

www.vanairsystems.com