Van Air Systems FD-250 blast-pak User Manual

Page 4

PAGE 4

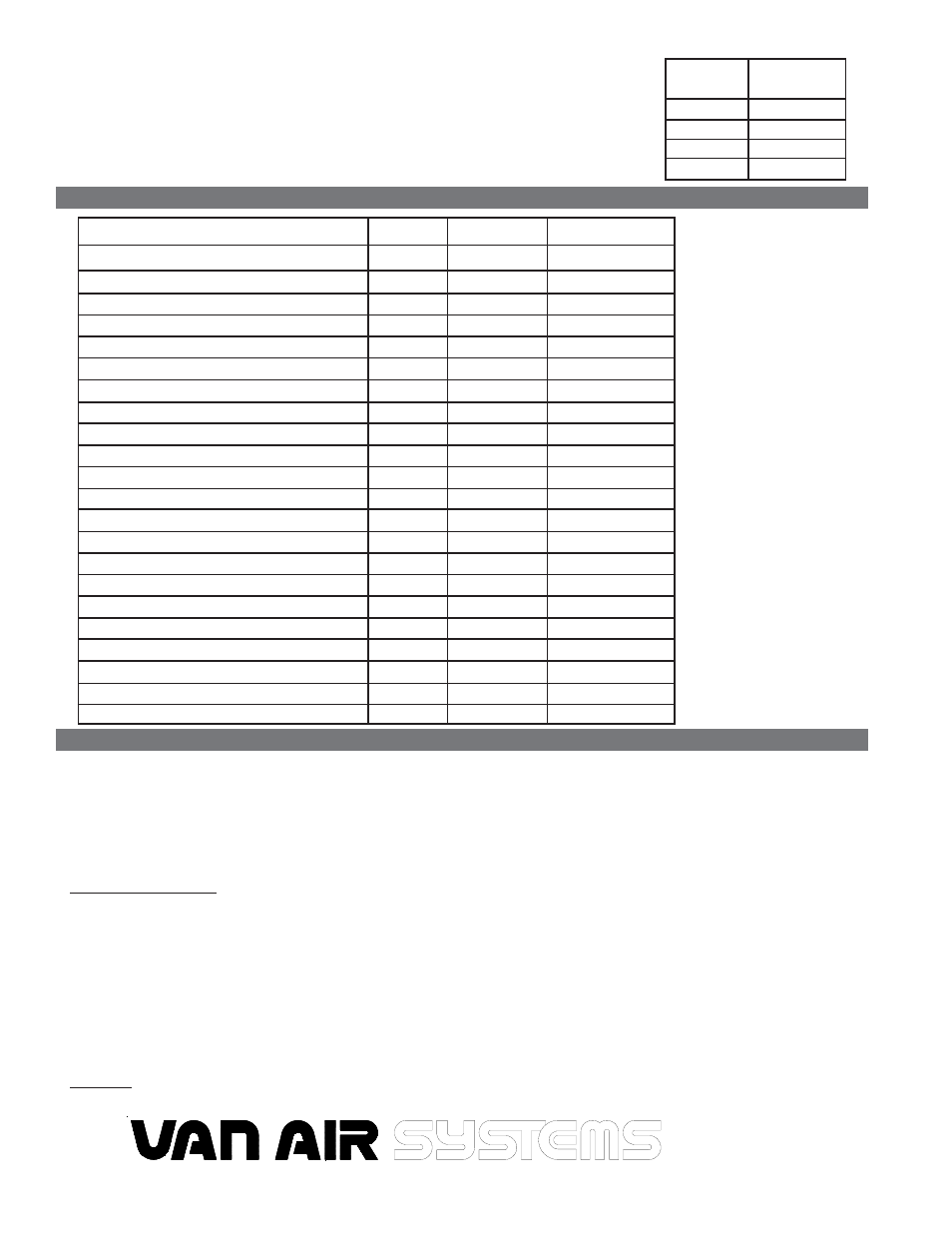

FD-250 QTY

1

1

2

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

-

FD-250-DC QTY

1

1

2

1

1

-

-

-

-

2

-

1

1

1

1

1

1

1

1

1

1

SECTION 6

REPLACEMENT PARTS

DESCRIPTION

Gasket for 3"x4" hatch cover

Hatch Cover, 3" x 4"

Sight Window

Manual Drain Valve 1" NPT

Manual Drain Valve 1/2" NPT

Air Motor for Aftercooler

Filter-Regulator-Lubricator

Element for FRL

Oil for Lubricator (Quart)

DESICCANT - DRY-O-LITE, 50 LB BAG

Flushing Solvent

OPTIONAL EQUIPMENT

Relief Valve 1/2" NPT 200# set pressure

Pressure gauge kit

Pressure gauge only

Temperature gauge kit

Temperature gauge only

Thermowell only

Combination pressure/temperature gauge

Automatic drain valve PDV-500T

White touch up paint (9 oz. spray can)

Male connector for 12 VDC motor wires

PART NO.

18-0391

46-3002

26-0104

14-0451

14-0450

26-6277

26-7039

26-7056

26-7032

33-0311

26-7157

14-1810

29-0252

29-0151

29-0326

29-0108

29-0107

29-0200

39-0284

45-0152

26-7178

2950 Mechanic Street

Lake City, PA 16423-2095

Phone: 814-774-2631

www.vanairsystems.com

The air motor on the FD-250 cooler needs to be flushed to remove excessive dirt, foreign particles, moisture and/or oil that accumulate in the air

motor during normal operation. Flushing helps to maintain proper motor performance and extend service life. Perform flushing procedure when

BlastPak is to be idle for more than 5 days, or if it is to be placed in storage.

Use Van Air Flushing Solvent (p/n 26-7157). DO NOT use kerosene or ANY other combustible solvents to flush the air motor.

Shutdown the air supply to the BlastPak and open the afterfilter drain valve to completely depressurize the system.

FLUSHING PROCEDURE

1. Remove the 1/4" NPT plug from the tee in the air line at air motor.

2. Remove the exhaust muffler from the air motor.

3. Spray flushing solvent (Van Air p/n 26-7157) directly into tee where plug was removed for 5 to 10 seconds.

4. Rotate motor shaft/fan, by hand in both directions for several revolutions.

5. Install the 1/4" NPT plug back into the tee and cover the motor exhaust port with a cloth.

6. You must wear eye protection for this step. Restart the air motor at a low pressure (approx. 10 PSIG) and run it until there is no trace of

solvent in the exhaust air.

7. Listen for changes in the sound of the motor. If the motor sounds smooth, the BlastPak is ready for storage. If the motor is not running

smooth, it will need to be serviced.

8. Disassemble the exhaust muffler that was removed in step 2. Clean the felt and reassemble the exhaust muffler.

9. Install the exhaust muffler on the air motor.

STORAGE

Store the Blast Pak in a location that is free from extreme humidity and corrosive gasses, which can cause damage to the unit.

SECTION 7

PREPARATION FOR STORAGE (FD-250 only)

FLOW

SCFM

100

150

200

250

DRY-O-LITE

LBS/YEAR

132

198

264

330

(This chart is based on 1 shift for a one year period (2,000 hours)@ 100 psig inlet pressure and 75

o

F inlet

temperature into dryer vessel, 100% RH.)

The consumption rate is proportional to the moisture loading. Each 20

o

F increase in inlet temperature

changes the moisture loading by a factor of nearly 2:1.

For special applications requiring desiccants other than DRY-O-LITE, consult factory.