Maintenance, Warning – Van Air Systems D2 User Manual

Page 4

PAGE 4

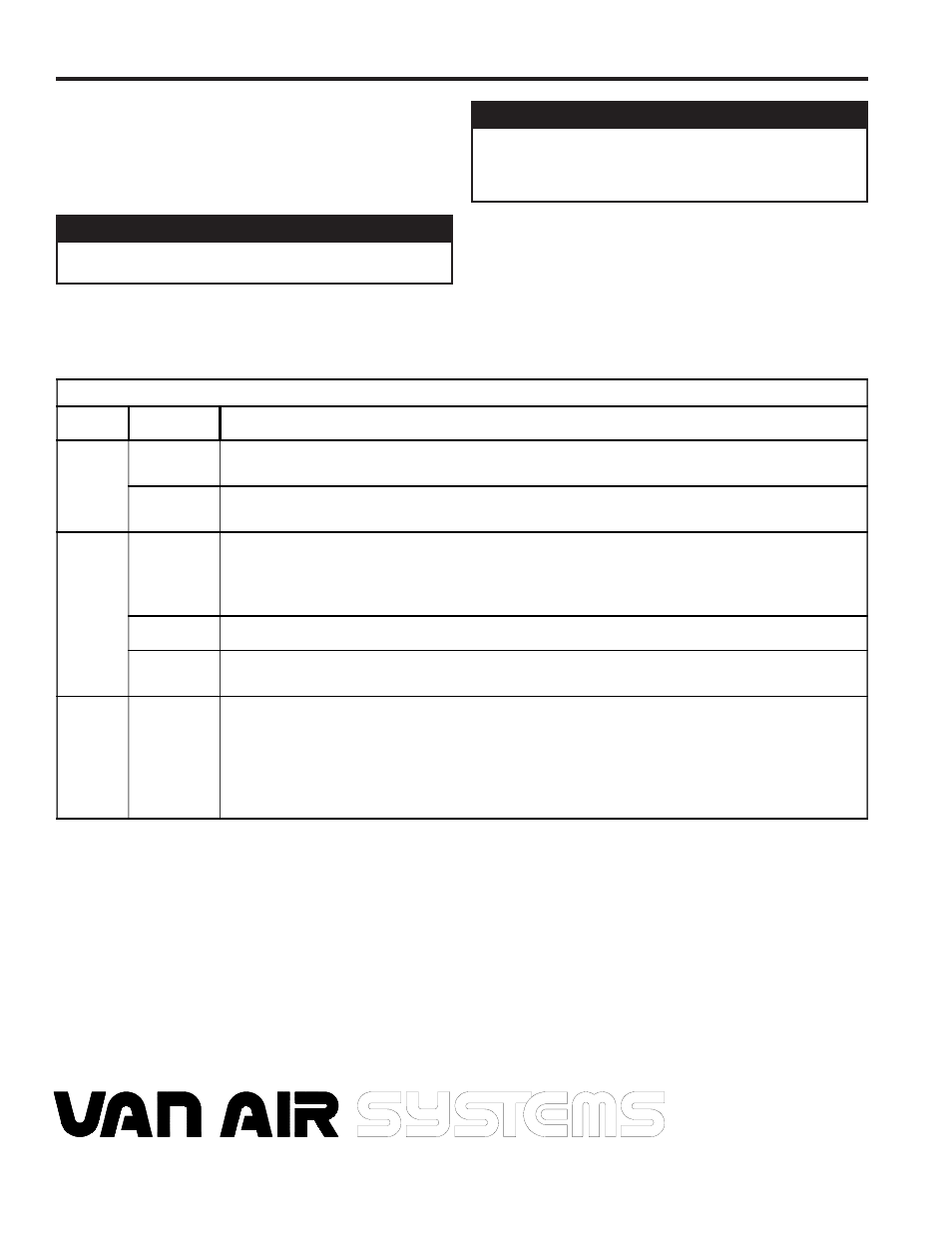

TROUBLE SHOOTING

CONDITION

POTENTIAL

CAUSE

RECOMMENDATION

Decreased

performance

or increased

desiccant

usage.

High inlet air

temperatures.

Check the aftercooler performance to make sure the airstream temperature is under 100°F. Make sure that the aftercooler was properly

sized and installed. Check the aftercooler operation manual for further details.

If an aircooler was not installed, one may be required.

High ambient

temperatures.

Check the location of the dryer for changes in ambient temperatures. If a piece of equipment or piping installed near the dryer is creating

the increase in temperature, relocate the dryer or equipment if possible. If relocation is not possible, correct the increased ambient

temperature through insulation or another method.

Liquid

downstream

of dryer.

Improper

draining.

Drain dryer at least once every 8 hours of operation.

Check the drain valve and piping for clogs. Repair or replace faulty valves. Clean any clogged piping. If freezing occurs, raise ambient

temperature or wrap piping and dryer with heat tracing and/or insulation.

Inspect separator. Remove water with better separation.

If a separator was not installed, one may be required.

Check the compressor capacity or air usage vs. the dryer rating.

Bypass valve

open or faulty

Check the dryer bypass valve. Replace or repair if necessary.

Low or no

desiccant in

dryer.

Check dryer desiccant bed level. Fill dryer as needed (Reference Figure 1).

Decreased

performance,

low

desiccant

usage.

Contaminated

desiccant bed.

Dryer can operate with normal amounts of compressor lubricant. If compressor manufacturer's recommended lubrication rate is exceeded,

the desiccant bed can become contaminated with lubricant.

Periodically check the desiccant bed. If tablets are discolored (deep yellow or brown), the bed is contaminated. If bed has become

contaminated, remove and discard desiccant, clean out dryer and install new desiccant. Remedy contamination problem before opening

bypass piping.

Check the compressor for proper operation. The compressor may be worn or over lubricated. Check the compressor operator's manual.

Check the atmospheric air near the compressor air intake. Heavy concentrations of acid fumes or smoke and dust will cause

contamination. Install a filter on the compressor intake. If it is not possible to reduce the amount of lubricants in the air system, install a

separator and/or coalescing filter upstream of the dryer.

MAINTENANCE

DO NOT OPERATE DAMAGED OR LEAKING DRYER, REMOVE

FROM SERVICE IMMEDIATELY.

WARNING

IF UNIT IS NOT DRAINED REGULARLY, FLOODING OF

DRYER MAY OCCUR. IF FLOODING OCCURS, ACCUMU-

LATED LIQUID MAY CARRY OVER AND RESULT IN DAM-

AGE TO DOWNSTREAM EQUIPMENT.

WARNING

Drain dryer at least once during each 8-hour shift.

Check desiccant bed weekly. Inspect the desiccant bed level

by looking through the sight glass window (Reference Figure

1). More tablets must be added when bed level falls below low

level (Reference Figure 1). Use Van Air Dry-O-Lite Desiccant

P/N: 33-0313 (50 lb pail).

1.

2.

2950 Mechanic Street

Lake City, PA 16423-2095

Phone: 814-774-2631

Fax: 814-774-3482

www.vanairsystems.com